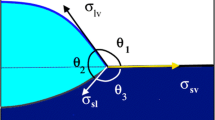

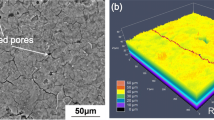

The contact and capillary processes that occur in the interaction of eutectic Nb melts containing Co, Ni, and Fe with Al2O3–SiO2 and AlN–TiN solid substrates at 1400–1450°C in 10–3 Pa vacuum have been considered. The microstructure and phase composition of the interaction products in the contact area have been examined, and thermodynamic analysis of potential reactions has been performed. The effect of the solvent metal for niobium on these processes has been determined, and explanation for the different wettabilities of the same substrates has been proposed in terms of the properties (composition and structure) of the solid phase formed at the metal–ceramic interface. An example of the potential application of these melts for brazing nonmetallic materials is provided.

Similar content being viewed by others

References

I.I. Metelkin, M.A. Pavlova, and N.V. Pozdeev, Welding of Ceramics with Metals [in Russian], Moscow (1997), p. 159.

M.L. Shalz, B.J. Dalgleish, A.P. Tomsia, R.M. Cannon, and A.M. Glaeser, “Ceramic joining: III. Bonding of alumina via Cu/Nb/Cu interlayers,” J. Mater. Sci., 29, No. 14, 3678–3690 (1994).

J.D. Sugar, J.T. McKeown, and R.A. Marks, “Liquid-film-assisted formation of alumina/niobium interfaces,” J. Am. Ceram. Soc., 85, No. 10, 2523–2530 (2002).

J.T. McKeown, J.D. Sugar, R. Gronsky, and A.M. Glaeser, “Effects of impurities on alumina–niobium interfacial microstructures,” Mater. Charact., 57, 50–57 (2006).

O.F. De Lima, M. Krehl, and M. Schuzek, “Wetting characteristics of copper on niobium,” J. Mater. Sci., 20, 2464–2470 (1985).

A.P. Tomsia, E. Saiz, S. Foppiano, and R.M. Cannon, “Reactive wetting: Ridging, adsorption, and compound formation,” in: Proc. 2nd Int. Conf. High Temperature Capillarity HTC–97 (Cracow, Poland, 1997), Cracow (1998), pp. 59–80.

V.S. Zhuravlev, N.Yu. Taranets, A.Yu. Koval, M.V. Karpets, and Yu.V. Naidich, “Wetting and interface microstructure in the system of Al2O3–SiO2 based ceramics/Nb-containing melts,” Open Ceram. Sci. J., 2, 8–14 (2012).

Yu.V. Naidich, V.S. Zhuravlev, V.G. Chuprina, and L.V. Strashinskaya, “Adhesion, wetting, and formation of intermediate phases in systems composed of a titanium-containing melt and an oxide,” Powder Metall. Met. Ceram., 12, No. 11, 895–899 (1973).

FACT, Fact-Web, Reaction-Web-properties of a species or chemical reaction, URL: http://www.crct.polymtlca/fact.

T.B. Massalski and H. Okamoto, Binary Alloy Phase Diagrams, 2nd ed., Ohio, USA (1990), p. 3589.

F. Valenza, M.L. Muolo, A. Passerone, and A.M. Glaeser, “Wetting and phenomena in joining of alumina via Co/Nb/Co interlaуers,” J. Eur. Ceram. Soc., 33, 539–547 (2013).

I.S. Kulikov, Thermal Dissociation of Compounds [in Russian], Moscow (1969), p. 574.

G.V. Samsonov, Nitrides [in Russian], Kyiv (1969), p. 377.

Y. Nakao, K. Nishimoto, and K. Saida, “Reaction layer in nitride ceramics (Si3N4 and AlN) to metal joints bonded with active filler metals,” ISIJ Int., 30, No. 12, 1142–1150 (1991).

T.N. Rezukhina, L.I. Kravchenko, and B.S. Pokarev, “Thermodynamic properties of Laves phases,” in: Metal Physics (Republican Interagency Collection of Papers) [in Russian], Kyiv (1973), Issue 46, pp. 21–28.

V.I. Alekseev, G.B. Petrov, and G.V. Shcherbediiskii, “Study of thermodynamic properties of Ni–Nb alloys,” Izv. Akad. Nauk SSSR. Met., No. 5, 59–62 (1978).

V.N. Drobyshev, Thermodynamic Study of Some Alloys of Molybdenum and Niobium with Iron Group Metals [in Russian], Author’s Abstract of PhD Thesis in Chemical Sciences, Moscow (1965), p. 14.

V.S. Zhuravlev, N.Yu. Taranets, A.Yu. Koval, M.V. Karpets, and Yu.V. Naidich, “Scientific and technical fundamentals for use of niobium of an adhesive component in metallic brazes for joining oxide and nitride materials,” Adhez. Rasp. Paika Mater., No. 43, 78–90 (2010).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Poroshkova Metallurgiya, Vol. 57, Nos. 9–10 (523), pp. 94–104, 2018.

Rights and permissions

About this article

Cite this article

Zhuravlev, V.S., Sydorenko, T.V., Karpets, M.V. et al. Contact and Capillary Processes in Systems Promising for Brazing: Eutectic Melts of Niobium with Cobalt, Nickel, and Iron–Nonmetallic Al2O3–SiO2 and AlN–TiN Materials. Powder Metall Met Ceram 57, 573–581 (2019). https://doi.org/10.1007/s11106-019-00018-7

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11106-019-00018-7