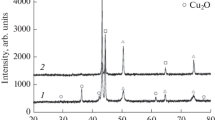

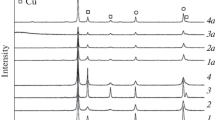

The phase composition and structurization of three types of copper and molybdenum composite materials, 0.8 to 5 mm thick, which were condensed from the vapor phase at substrate temperatures 700 and 900°C, are considered: precipitation-strengthened composites, microlayered composites with alternating copper and molybdenum layers 1 to 10 μm thick, and bulk nanocrystalline composites with alternating layers thinner than 0.5 μm. Standard precipitation-strengthened Cu- and Mo-based materials condensed from the vapor phase at substrate temperatures 700–900°C can be produced over a relatively narrow composition range of the strengthening phase (0.1–3 wt.% Mo). When Mo content is 3–5 wt.%, the molybdenum particles change their shape from round to acicular and become discontinuous chains oriented perpendicularly to the vapor flow. If there is more than 5 wt.% of the second phase, the condensed composite materials (CCMs) show a layered structure. The layered structure can be observed in other CCM types (Cu–W, Cu–Cr, NiCrAlTi–Al2O3). Layered copper and molybdenum CCMs, 6 mm thick, produced on a rotating substrate heated to 700 ± 30°C have been experimentally confirmed to belong to bulk nanocrystalline materials.

Similar content being viewed by others

References

R. F. Bunshah, “Vacuum evaporation—history, recent development, and application,” Z. Metallkd., 75, No. 11, 840–846 (1984).

I. L. Roikh, L. N. Koltunova, and S. N. Fedosov, Application of Protective Coatings in Vacuum [in Russian], Mashinostroenie, Moscow (1976), p. 362.

B. A. Movchan and I. S. Malashenko, Oxidation-Resistant Coatings Deposited in Vacuum [in Russian], Naukova Dumka, Kyiv (1983), p. 250.

A. Kushner (ed.), Surface Quality Improvement and Metal Cladding [in Russian], Metallurgiya, Moscow (1984), p. 376.

A. I. Kostorzhitskii and O. V. Lebedinskii, Multicomponent Vacuum Coatings [in Russian], Mashinostroenie, Moscow (1987), p. 207.

B. A. Movchan and K. Yu. Yakovchuk, “Electro-beam units for evaporation and deposition of inorganic materials and coatings,” Spets. Elektrometall., No. 2, 10–15 (2004).

N. I. Grechanyuk, P. P. Kucherenko, and I. N. Grechanyuk, “New electron-beam equipment and technologies for producing modern materials and coatings,” Avtomat. Svarka, No. 5, 36–41 (2007).

N. I. Grechanyuk, P. P. Kucherenko, A. G. Melnik, et al., “New electron-beam equipment and technologies for producing modern materials by melting and evaporation in vacuum developed by Eltekhmash Research and Manufacturing Company,” Avtomat. Svarka, No. 5–6, 53–60 (2016).

N. I. Grechanyuk, “Capabilities of electron-beam production of composite materials,” in: Electrical Contacts and Electrodes Series (Collected Papers) [in Russian], Inst. Probl. Materialoved. NAN Ukrainy, Kyiv (2010), pp. 44–53.

N. I. Grechanyuk, “Composite materials with a metal matrix condensed from the vapor phase. I. Precipitation-strengthened materials,” in: Physicochemical Principles for Powder Material Technology. Modern Problems of Physical Materials Science Series (Collected Papers) [in Russian], Inst. Probl. Materialoved. NAN Ukrainy, Kyiv (2010), Issue 19, pp. 3–9.

N. I. Grechanyuk, “Composite materials with a metal matrix condensed from the vapor phase. II. Microlayered materials,” in: Physicochemical Principles for Powder Material Technology. Modern Problems of Physical Materials Science Series (Collected Papers) [in Russian], Inst. Probl. Materialoved. NAN Ukrainy, Kyiv (2010), Issue 19, pp. 10–16.

N. I. Grechanyuk, “Composite materials with a metal matrix condensed from the vapor phase. III. Microporous materials,” in: Electron Microscopy and Strength of Materials. Physical Materials Science, Structure, and Properties of Materials Series (Collected Papers) [in Russian], Inst. Probl. Materialoved. NAN Ukrainy, Kyiv (2012), Issue 18, pp. 162–169.

H. Gleiter, “Nanostructured materials: basic concepts and microstructure,” Acta Metall., 48, 1–29 (2000).

V. V. Skorokhod, I. V. Uvarova, and A. V. Ragulya, Physicochemical Kinetics in Nanostructured Systems [in Ukrainian], Akademperiodika, Kyiv (2001), p. 179.

S. I. Sidorenko, “Limit states in thin metallic films,” in: Inorganic Materials Science. Fundamentals of Materials Science [in Russian], Naukova Dumka, Kyiv (2008), Vol. 1, pp. 459–481.

Zhov Ling-ping, Wang-Ming-pu, Peng Kun, et al., “Structure characteristic and evolution of Cu–W films prepared by dual-target magnetron sputtering deposition,” Trans. Nonferrous Met. Soc. China, 22, 2700–2706 (2012).

B. A. Movchan and A. V. Demchishin, “Study of the structure and properties of thick vacuum condensates of nickel, titanium, tungsten, and alumina,” Fiz. Met. Metalloved., 28, No. 4, 653–660 (1969).

D. M. Karpinos (ed.), Composite Materials: Handbook [in Russian], Naukova Dumka, Kyiv (1985), p. 591.

Yu. V. Naidich, Contact Phenomena in Metal Melts [in Russian], Naukova Dumka, Kyiv (1972), p. 196.

L. I. Maissel and R. Glang, Handbook of Thin Film Technology, McGraw-Hill, New York (1970).

G. G. Gnesin (ed.), Sintered Materials for Electrical Engineering and Electronics: Handbook [in Russian], Metallurgiya, Moscow (1981), p. 343.

A. V. Demchishin, Structure and Properties of Thick Vacuum Condensates of Metallic and Nonmetallic Materials and Scientific Principles for Their Production [in Russian], Author’s Abstract of ScD Thesis, Kyiv (1981), p. 35.

V. G. Grechanyuk, Physicochemical Principles for Producing Copper-Based Coatings from Composite Materials Condensed from the Vapor Phase [in Ukrainian], Author’s Abstract of ScD Thesis, Kyiv (2013), p. 40.

V. V. Shcherbitskii, N. I. Grechanyuk, and P. P. Kucherenko, “Electron-beam unit for producing multilayered materials,” Probl. Spets. Elektrometall., No. 16, 51–53 (1982).

N. I. Grechanyuk, V. A. Osokin, I. N. Grechanyuk, et al., “Copper and molybdenum composite materials for electrical contacts condensed from the vapor phase. Structure, properties, and technology. II. Fundamentals of electron-beam technology for producing materials for electrical contacts,” Sovr. Elektrometall., No. 2 (83), 9–19 (2006).

V. A. Rabinovich and Z. Ya. Khavin, Concise Chemical Handbook [in Russian], Khimiya, Leningrad (1978), p. 392.

B. A. Movchan, V. A. Osokin, L. V. Pushechnikova, and N. I. Grechanyuk, “Electron-beam evaporation of copper through an intermediate bath,” Probl. Spets. Elektrometall., No. 3, 58–61 (1991).

G. Zinsmeister, “The direct evaporation of alloys,” Vak. Tech., No. 8, 233–240 (1964).

N. I. Grechanyuk, E. V. Onoprienko, and V. G. Grechanyuk, “Structural zones in vacuum condensates,” in: Electrical Contacts and Electrodes. Composite Layered and Gradient Materials and Coatings Series (Collected Papers) [in Russian], Inst. Probl. Materialoved. NAN Ukrainy, Kyiv (2012), pp. 179–183.

N. P. Lyapishev (ed.), Phase Diagrams of Binary Metallic Systems: Handbook, 3 Vols. [in Russian], Mashinostroenie, Moscow (1997), Vol. 2, pp. 275–276.

M. V. Belous and K. M. Uimen, “Thermal effects in vapor condensation of thin films,” in: Proc. First Conf. Acicular Crystals and Nonferromagnetic Films [in Russian], Voronezh (1970), Part. II, pp. 101–107.

N. I. Grechanyuk, V. I. Topal, B. A. Movchan, and T. A. Molodkina, “Structure and properties of thick Cu–Mo condensates,” Spets. Elektrometall., No. 60, 38–43 (1986).

N. I. Grechanyuk, V. I. Topal, B. A. Movchan, et al., “Structure and properties of Cu–Mo condensates with directionally distributed particles of the second phase,” Spets. Elektrometall., No. 68, 53–57 (1990).

B. A. Movchan, N. I. Grechanyuk, V. A. Osokin, and T. A. Molodkina, “Structure, mechanical properties, and thermal stability of condensed precipitation-strengthened Cu–Y–Mo materials. Part I,” Probl. Spets. Elektrometall., No. 4, 27–32 (1991).

B. A. Movchan, T. A. Molodkina, Yu. F. Lugovskoi, et al., “Fatigue strength and dislocation structure of condensed Cu–Mo materials,” Fiz. Khim. Obrab. Mater., No. 1, 139–142 (1992).

B. A. Movchan, N. I. Grechanyuk, V. A. Osokin, et al., “Electrical conductivity, oxidation-resistance, and linear thermal expansion coefficient of condensed precipitation-strengthened Cu–Y–Mo materials. Part II,” Probl. Spets. Elektrometall., No. 1, 57–60 (1992).

B. A. Movchan, S. A. Fabritsiev, and N. I. Grechanyuk, “Radiation resistance of condensed precipitation-strengthened Cu–Y– Mo materials. Part III,” Probl. Spets. Elektrometall., No. 1, 61–64 (1992).

B. A. Movchan, N. I. Grechanyuk, V. A. Osokin, et al., “Effect of cold working on the structure and mechanical properties of condensed Cu–Y–Mo materials. Part IV,” Probl. Spets. Elektrometall., No. 1, 42–50 (1993).

B. A. Movchan, L. M. Nerodenko, T. A. Molodkina, et al., “Substructure and mechanical properties of precipitation-strengthened Cu–Y–Mo condensates deformed at different temperatures and rates,” Probl. Spets. Elektrometall., No. 4, 29–34 (1993).

V. A. Osokin, Structure, Properties, and Electron-Beam Production of Copper Composite Materials [in Russian], Author’s Abstract of PhD Thesis, Inst. Elektrosvark. NAN Ukrainy, Kyiv (1990), p. 29.

B. A. Movchan and N. I. Grechanyuk, “Structure and some properties of microlayered condensed materials,” Probl. Spets. Elektrometall., No. 20, 68–73 (1984).

N. I. Grechanyuk, G. G. Didikin, and B. A. Movchan, “Study of the hardness, strength, and plasticity of microlayered chromium–copper materials,” Probl. Spets. Elektrometall., No. 18, 57–59 (1983).

V. V. Bukhanovskii, N. I. Grechanyuk, N. P. Rudnitskii, et al., “Effect of the composition and process factors on the structure, mechanical properties, and fracture of copper–chromium composite materials,” Metalloved. Term. Obrab. Met., No. 8, 26–31 (2009).

N. I. Grechanyuk, Method for Producing Microlayered Heat-Resistant Materials [in Ukrainian], Ukrainian Patent 74155, publ. November 15 (2005).

N. I. Grechanyuk, Method for Producing Microlayered Heat-Resistant Materials [in Russian], Russian Federation Patent 2271404, publ. October 3 (2006).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Poroshkovaya Metallurgiya, Vol. 56, Nos. 11–12 (518), pp. 29–46, 2017.

Rights and permissions

About this article

Cite this article

Grechanyuk, N.I., Grechanyuk, V.G. Precipitation-Strengthened and Microlayered Bulk Copper- and Molybdenum-Based Nanocrystalline Materials Produced by High-Speed Electron-Beam Evaporation–Condensation in Vacuum: Structure and Phase Composition. Powder Metall Met Ceram 56, 633–646 (2018). https://doi.org/10.1007/s11106-018-9938-4

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11106-018-9938-4