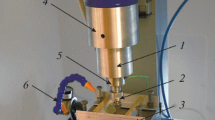

The structure, phase composition, and hardness of electrode materials produced by hot pressing of TiC–(Fe–9% Cr–1.5% Si–2% Al) alloys were examined. The binder amount in the alloys varied from 20 to 90 wt.%. The phase composition, hardness, and oxidation resistance of the electrosparkdeposited coatings made of the developed materials were studied at 900°C with holding for 35 h, and their abrasive wear resistance was tested. It was determined how hot-pressing temperature of the electrode alloys and the spark discharge energy influenced the cathode (steel 45) weight increment in the electrospark deposition process employing an ELITRON-22A unit. The developed electrode materials were used to make a coating 120–160 μm thick, with the total thickness of the strengthened layer and transition zone being 240–270 μm, with 8.5–14.5 GPa microhardness (depending on the binder content of the alloys). The abrasive wear resistance and oxidation resistance of the electrospark-deposited coatings made of the developed alloys are two to three times higher than those of the coatings made of TiC hard alloys with Co–Cr, Co–Ni, and Ni–Mo binders.

Similar content being viewed by others

References

A.D. Verkhoturov and I.M. Mukha, Technology of Electrospark Alloying of Metallic Surfaces [in Russian], Tekhnika, Kyiv (1988), p. 181.

C.C. Degnan, P.H. Shipway, and J.V. Wood, “Elevated temperature sliding wear behavior of TiCreinforced steel matrix composites,” Wear, No. 251, 1444–1451 (2001).

M. Komac and S. Novak, “Mechanical and wear behavior of TiC cemented carbides,” Int. J. Refract. Met. Hard Mater., No. 4, 21–26 (1985).

Yu.G. Gurevich, V.K. Narva, and N.R. Frage, Carburized Steels [in Russian], Metallurgiya, Moscow (1988), p. 144.

J. Kübarsepp, Hard Alloys with a Steel Binder [in Russian], Valgus–TUU, Tallinn (1991), p. 164.

A.I. Rakitskii, T.L. Kuznetsova, and I.E. Poryadchenko, “Study of some properties of high-chromium cast iron–chromium alloys,” Metallofiz. Noveish. Tekhnol., 19, No. 6, 74–77 (1997).

V.A. Maslyuk, R.V. Yakovenko, O.A. Potazhevska, and A.A. Bondar, “Hard powder alloys and carburized chromium steels in the Cr–Fe–C system,” Powder Metall. Met. Ceram., 52, No. 1–2, 47–57 (2013).

V.P. Gavrilyuk, V.G. Ivanchenko, and V.A. Loktionov-Remizovskii, “Effect of aluminum and carbon on the wear resistance of iron–chromium alloys,” Metalloznav. Obrob. Met., No. 3, 47–49 (2005).

Yu.S. Borisov, Yu.A. Kharlamov, S.L. Sidorenko, and E.I. Ardatovska, Thermal Sprayed Coatings from Powder Materials [in Russian], Naukova Dumka, Kyiv (1987), p. 544.

J.D. Bolton and A.J. Gant, “Structure development and sintering kinetics of ceramic reinforce high speed steel,” Powder Metall., 40, No. 2, 143–151 (1997).

Yu.G. Tkachenko, D.Z. Yurchenko, V.F. Britun, L.P. Isaeva, and V.T. Varchenko, “Structure and properties of wear-resistant spark-deposited coatings produced with a titanium carbide alloy anode,” Powder Metall. Met. Ceram., 52, No. 5–6, 306–313 (2013).

Yu. G. Tkachenko, D. Z. Yurchenko, V.F. Britun, M.A. Vasilkovska, and V.T. Varchenko, “Electrosparkdeposited coatings from titanium and tungsten carbide alloys: mass transfer kinetics, structurization, and properties,” Powder Metall. Met. Ceram., 54, No. 5–6, 309–317 (2015).

M.M. Khrushchev and M.A. Babichev, Abrasive Wear [in Russian], Nauka, Moscow (1980), p. 160.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Poroshkova Metallurgiya, Vol. 57, Nos. 7–8 (522), pp. 119–129, 2018.

Rights and permissions

About this article

Cite this article

Tkachenko, Y.G., Yurchenko, D.Z., Timofeeva, I.I. et al. Effect from the Composition of Electrodes Produced from TiC–(Fe–Cr–Al–Si) Alloys on the Formation, Phase Composition, and Properties of Wear- and Oxidation-Resistant Electrospark-Deposited Coatings on Steel. Powder Metall Met Ceram 57, 465–472 (2018). https://doi.org/10.1007/s11106-018-0005-y

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11106-018-0005-y