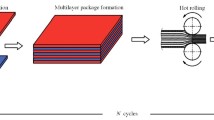

Multilayer materials (1.2–0.25 mm thick) are produced by sintering in a container at 850°C and cold rolling of ten-layer briquettes of commercially pure iron. It is shown that the tensile strength of the materials studied is proportional to the total true strain value by rolling and reaches 1400 MPa at percentage extension 1%. Endurance limit increases up to 670 MPa. With increasing strain degree by rolling, the structural elements inside layers reduce in size, when high interlayer strength between macro layers. The best correlation of endurance limit of materials with micro yield strength is observed, when 0.01% of residual strain.

Similar content being viewed by others

References

M. I. Karpov, V. P. Korzhov, V. M. Kiyko, et al., “Effect of pressure heat treatment on the structure of Ni/Al multilayer composites,” Perspekt. Mater., No. 13, 704–712 (2011).

V. P. Korzhov, M. I. Karpov, and D. V. Prokhorov, “Multilayer structure and high-temperature strength of heat-resistant materials based on Nb−Al−Si compounds produced of Nb−Al and Nb−Si composites,” Fiz. Tekh. Vys. Davl., 23, No. 1, 99–107 (2013).

S. Yu. Didenko, N. I. Il’chenko, I. M. Neklyudov, and S. L. Bondarenko, “Producing copper–steel multilayer and composite materials by vacuum hot rolling and studying their properties,” Vopr. Atom. Nauk. Tekh., No. 3, 158–160 (2003).

I. M. Neklyudov, V. A. Belous, V. N. Voyevodin, et al., “Prospects for the production and use of metal micro laminates produced by vacuum rolling,” Vopr. Atom. Nauk. Tekh., No. 5, 89–94 (2010).

Y. Saito, H. Utsunomiya, N. Tsuji, and T. Sakai, “Novel ultra-high straining process for bulk materials development of the accumulative roll-bonding (arb) process,” Acta Mater., 47, No. 2, 579–583 (1999).

S. A. Firstov, N. I. Danilenko, Yu. N. Podrezov, et al., “Investigation of the substructure of sintered iron powder by transmission electron microscopy,” Powder Metall. Met. Ceram., 29, No. 6, 468–471 (1990).

V. A. Kuzmenko, Acoustic and Ultrasonic Vibrations in Dynamic Tests of Materials [in Russian], AN UkrSSR, Kiev (1963), p. 152.

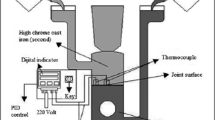

Yu. F. Logovskoi, “Procedure for bending fatigue tests of composites obtained by electron-beam evaporation,” Prob. Spets. Elektrometal., No. 4, 61–65 (1987).

Yu. N. Podrezov, N. I. Danilenko, and D. G. Verbilo, “Structural sensitivity of mechanical properties of prestressed BCC-metals,” in: Electron Microscopy and Strength of Materials, Ins. Prob. Mater. NAN Ukrainy, Kiev (1996), pp. 45–61.

S. A. Firstov, Yu. N. Podrezov, V. I. Kopylov, and N. I. Danilenko, “Structural sensitivity of mechanical properties of ECAP-processed armco iron,” Metally, No. 1, 54–62 (2004).

G. Langford and M. Cohen, “Strain hardening of iron by severe plastic deformation,” Trans. ASM, 62, 623–629 (1965).

V. T. Troshchenko and L. A. Sosnovskii, Fatigue Resistance of Metals and Alloys: Handbook [in Russian], Part 2, Nauk. Dumka, Kiev (1987), p. 1100.

V. F. Terentyev, “Cyclic strength of sibmicro- and nanocrystalline metals and alloys (Review),” Novi Mater. Tekhnol., No. 1, 8–24 (2010).

M. N. Stepnov, Statistical Methods for Processing Mechanical Test Results: Handbook [in Russian], Mashinostroyeniye, Moscow (1985), p. 232.

K. O. Gogaev, V. A. Nazarenko, and Yu. F. Lugovskyi, Method of Manufacturing Billets of Metal Laminated Materials [in Ukrainian], Patent for useful model No. 107192 Ukraine, Bull. No. 10, May 25 (2016).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Poroshkovaya Metallurgiya, Vol. 56, Nos. 5–6 (515), pp. 10–19, 2017.

Rights and permissions

About this article

Cite this article

Lugovskoi, Y.F., Podrezov, Y.N., Nazarenko, V.A. et al. Mechanical Properties and Fracture Mechanisms of Commercially Pure Multilayer Iron Produced by Strip Joint Rolling. Powder Metall Met Ceram 56, 245–252 (2017). https://doi.org/10.1007/s11106-017-9892-6

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11106-017-9892-6