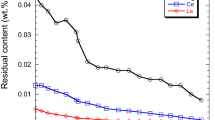

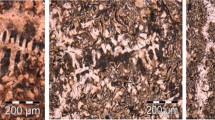

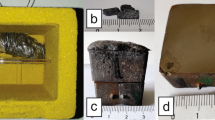

The features of dissolution of briquetted powder inoculants with different compositions (92% Fe–8% Mg; 42% Fe–8% Mg–50% Cu, and 92% Cu–10% Mg) in a cast iron melt, including their densities and geometric characteristics, are investigated. It is shown that the dissolubility of briquetted inoculants in the melt decreases with increasing porosity from 8 to 15%, while increases with increasing porosity up to 30%. The introduction of copper into the composition of briquetted inoculants enhances their dissolution intensity and degree of magnesium recovery by the cast iron melt. It is established that the application of Fe–Cu–Mg inoculants provides the maximum values of graphite particles shape factor and strength properties of the cast iron at optimal temperatures (1400 and 1420°C) of melt processing.

Similar content being viewed by others

References

V. E. Khrychikov and L. Kh. Ivanova, “Casting technique for mill rolls of multi-component inoculated cast irons,” Such. Prob. Metal., 9, 27–36 (2006).

E. V. Kolotilo, L. Kh. Ivanova, and Yu. K. Bunina, “Casting technique for producing mill rolls of multicomponent inoculated nodular cast irons,” Teor. Prakt. Metall., No. 6, 45–49 (2000).

L. Kh. Ivanova, Ya. S. Maymur, I. A. Osipenko, et al., “Multi-component inoculated roll-foundry irons,” Visn. Donbas. Derzh. Mashinobud. Akad., 32, No. 1, 75–79 (2014).

D. Löhe, O. Vöhringer, and E. Macherauch, “The influence of graphite shape on mechanical properties of ferritic cast iron,” Mechan. Behaviour Mater., 3, 179–188 (1980).

P. Canzar, Z. Tonkovic, and J. Kodvanj, “Microstructure influence on fatigue behaviour of nodular cast iron,” Mater. Sci. Eng. A, 556, No. 30, 88–99 (2012).

Q. Luo, J. Xie, and Y. Song, “Effects of microstructures on the abrasive wear behaviour of spheroidal cast iron,” Wear, 184, No. 1, 1–10 (1995).

V. I. Litovka, Improving Quality of As-Cast Ductile Iron [in Russian], Nauk. Dumka, Kiev (1987), p. 208.

Ya. E. Gol’dshtein and V. G. Midin, Inoculation and Micro-Alloying of Iron and Steel [in Russian], Mashinostroyenie, Moscow (1988) p. 272.

V. I. Litovka, V. A. Maslyuk, V. Ya. Kurovskii, et al., “Producing ductile cast iron with use of briquetted inoculants,” Lit. Proiz., No. 8, 7–12 (2003).

V. Ya. Kurovskii and G. A. Baglyuk, “Features of Cast Iron Treatment with Briquetted Powder Modifiers in Manufacturing of Forming Rolls,” in: Machines Technologies Materials (10th Int. Congress Proc. 10–12 September 2013, Varna, Bulgaria), Vol. 1, Varna, Bulgaria (2013), pp. 93–96.

I. A. Kurkostriga and O. V. Sotsenko, “Effect of charge composition on graphite shape in bar-rolling rolls,” Met. Lit. Ukr., 213, No. 2, 7–12 (2011).

V. Ya. Kurovskii, G. A. Baglyuk, and O. Y. Shynskyi, “Effect of composition and compacting conditions on properties of briquetted inoculants,” Nauk. Notatki, Mezhvuz. Zb., No. 25, Part 2, 128–133 (2009).

G. A. Baglyuk, V. Ya. Kurovskii, and O. Y. Shynskyi, “Effect of compacting procedure of powder inoculants on the kinetics of their dissolution in a molten cast iron,” Visn. NTUU “Kyiv. Polytekh. Ins.,” Series Mashinobud., No. 59, 27–30 (2010).

K. V. Makarenko and Yu. M. Ivashchenko, “Inoculation of nodular cast iron,” Polzun. Al’manakh, Nos. 1–2, 107–109 (2007).

“Effect of Micro Coolers on Microinhomogeneity of Steels and Alloys” [in Russian], in: All about Metallurgy, Path-to-source:http://metal-archive.ru/mikroneodnorodnost/873-vliyanie-mikroholodilnikov-namikroneodnorodnost-staley-i-splavov.html

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Poroshkovaya Metallurgiya, Vol. 56, Nos. 3–4 (514), pp. 3–12, 2017.

Rights and permissions

About this article

Cite this article

Baglyuk, G.A., Kurovskii, V.Y. Effect of Composition and Properties of Briquetted Powder Inoculants on the Features of Their Dissolution in a Molten Roll-Foundry Iron. Powder Metall Met Ceram 56, 123–129 (2017). https://doi.org/10.1007/s11106-017-9879-3

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11106-017-9879-3