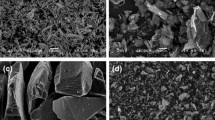

A novel powder metallurgy method, based on preparation of powder mixtures of copper with 0.5, 1, 1.5, 2, 2.5, 3, and 5 wt.% of nanographite particles ~50 nm in size, is used to produce Cu-nanographite electrical contact materials with flake microstructure. The dispersion of graphite nanoparticles in the Cu matrix is examined by scanning electron microscopy (SEM) and energy dispersive spectroscopy (EDS). Morphology, particle size, and apparent density of flake powders are investigated. Microstructure, density, electrical conductivity, and hardness are studied for green and sintered samples. The composites reinforced with lower graphite nanoparticles content (0.5 wt.%) exhibit much lower agglomeration content, while the composites reinforced with higher graphite nanoparticles content (5 wt.%) showed higher agglomeration content. It is found out that the electrical conductivity of the sintered Cu-nanographite electrical contact materials decreased from 76.92 to 68.28 IACS by graphite nanoparticle addition. The maximal (~34) and minimal (~20) Brinell hardness is obtained for the monolithic Cu sample and 5 wt.% graphite nanoparticle reinforced Cu electrical contact materials, respectively.

Similar content being viewed by others

References

Ö. Güler and E. Evin, “The investigation of contact performance of oxide reinforced copper composite via mechanical alloying,” J. Mater. Process Technol., 209, No. 3, 1286–1290 (2009).

Z. Mu, H. R. Geng, M. N. Li, et al., “Effects of Y2O3 on the property of copper based contact materials,” Composites: Part B, 52, 51–55 (2013).

S. S. Feng, H. R. Geng, and Z. Q. Guo, “Compaction study on Cu-based electrical contact materials by warm,” J. Funct. Mater., 42, 106–109 (2011).

W. Z. Shao, Y. S. Cui, and D. Z. Yang, “The development and current status of electrical contact materials,” Electr. Eng. Mater., 1,11–35 (1999).

T. Futami, M. Ohira, H. Muto, and M. Sakai, “Indentation contact behavior of copper–graphite particulate composites: correlation between the contact parameters and the electrical resistivity,” Carbon, 46, No. 4, 671–678 (2008).

D. Zhang and Z. Zhan, “Strengthening effect of graphene derivatives in copper matrix composites,” J. All. Compd., 654, 226–233 (2016).

J. Wang, R. Zhang, J. Xu, et al., “Effect of the content of ball-milled expanded graphite on the bending and tribological properties of copper–graphite composites,” Mater. Des., 47, 667–671 (2013).

P. Queipo, M. Granda, R. Santamaria, and R. Menendez, “Preparation of pitch-based carbon–copper composites for electrical applications,” Fuel, 83, Nos. 11–12, 1625–163 (2004).

G. S. Upadhayaya, Powder Metallurgy Technology, Cambridge International Science Publishing, England (2002), p. 159.

K. Rajkumar and S. Aravindan, “Tribological behavior of microwave processed copper-nanographite composites,” Tribol. Int., 57, 282–296 (2013).

M. Bravunovic, V. V. Konchits, and N. K. Myshkin, Electrical Contacts: Fundamentals, Applications and Technology, CRC Press, New York (2006), p. 646.

A. Azimi, A. Shokuhfar, and O. Nejadseyfi, “Mechanically alloyed Al7075–TiC nanocomposite: Powder processing, consolidation and mechanical strength,” Mater. Des., 66, Part A, 137–141 (2015).

M. Taskin, U. Caligulu, and A. K. Gur, “Modeling adhesive wear resistance of Al–Si–Mg/SiCp PM compacts fabricated by hot pressing process, by means of ANN,” Int. J. Adv. Manuf. Technol., 37, No. 7, 715–721 (2008).

M. Kök, “Computational investigation of testing parameter effects on abrasive wear behaviour of Al2O3 particle-reinforced MMCS using statistical analysis,” Int. J. Adv. Manuf. Technol., 52, No. 1, 207–215 (2011).

M. A. Milton, V. U. Alejandro, P. Rodrigo, and M. Edgar, “In situ production of tantalum carbide nanodispersoids in a copper matrix by reactive milling and hot extrusion,” J. All. Compd., 598, 126–132 (2014).

K. Dash, B. C. Ray, and D. Chaira, “Synthesis and characterization of copper–alumina metal matrix composite by conventional and spark plasma sintering,” J. All. Compd., 516, 78–84 (2012).

I. Celikyurek, N. O. Korpe, T. Olcer, and R. Gurler, “Microstructure, properties and wear behaviors of (Ni3Al)p reinforced Cu matrix composites,” J. Mater. Sci. Technol., 27, No. 10, 937–943 (2011).

L. Jiang, Z. Li, G. Fan, L. Cao, “The use of flake powder metallurgy to produce carbon nanotube (CNT)/ aluminum composites with a homogenous CNT distribution,” Carbon, 50, No. 5, 1993–1998 (2012).

W. Zhang, Z. Li, L. Jiang, et al., “Flake thickness effect of Al2O3/Al biomimetic nanolaminated composites fabricated by flake powder metallurgy,” Mater. Sci. Eng. A, 594, 324–329 (2014).

X. Kai, Z. Li, G. Fan, et al., “Strong and ductile particulate reinforced ultrafine-grained metallic composites fabricated by flake powder metallurgy,” Scr. Mater., 68, No. 8, 555–558 (2013).

X. Z. Kai, Z. Q. Li, G. L. Fan, et al., “Enhanced strength and ductility in particulate-reinforced aluminum matrix composites fabricated by flake powder metallurgy,” Mater. Sci. Eng. A., 587, 46–53 (2013).

H. H. Zhu, J. Y. H. Fuh, and L. Lu, “The influence of powder apparent density on the density in direct laser-sintered metallic parts,” Int. J. Mach. Tools Manuf., 47, No. 2, 294–298 (2007).

R. M. German, Particle Packing Characteristics, Metal Powder Industries Federation, New Jersey (1989), p. 443.

K. Rajkumar and S. Aravindan, “Microwave sintering of copper–graphite composites,” J. Mater. Process Technol., 209, No. 15–16, 5601–5605 (2009).

S. M. Uddin, T. Mahmud, C. Wolf, et al., “Effect of size and shape of metal particles to improve hardness and electrical properties of carbon nanotube reinforced copper and copper alloy composites,” Compos. Sci. Technol., 70, No. 16, 2253–2257 (2010).

O. Hjortstam, P. Isberg, S. Söderholm, and H. Dai, “Can we achieve ultra-low resistivity in carbon nanotube-based metal composites,” Appl. Phys A., 78, No. 8, 1175–1179 (2004).

M. Yusoff, R. Othman, and Z. Hussain, “Mechanical alloying and sintering of nanostructured tungsten carbide-reinforced copper composite and its characterization,” Mater. Des., 32, No. 6, 3293–3298 (2011).

S. Mahdavi and F. Akhlaghi, “Effect of the graphite content on the tribological behavior of Al/Gr and Al/30SiC/Gr composites processed by in situ powder metallurgy (IPM) method,” Tribol. Lett., 44, No. 1, 1–12 (2011).

Acknowledgments

This study has been supported by the Scientific and Technological Research Council of Turkey (TUBITAK) with the project number 114M070. The authors would like to express their sincere thanks and appreciations to The Scientific and Technological Research Council of Turkey (TUBITAK) for the financial assistance.

Author information

Authors and Affiliations

Corresponding author

Additional information

Published in Poroshkovaya Metallurgiya, Vol. 55, Nos. 7–8 (510), pp. 60–72, 2016.

Rights and permissions

About this article

Cite this article

Varol, T., Canakci, A. The Effect of Flake Microstructure on the Preparation and Properties of Cu–Graphite Sintered Nanocomposites. Powder Metall Met Ceram 55, 426–436 (2016). https://doi.org/10.1007/s11106-016-9823-y

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11106-016-9823-y