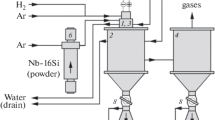

A more effective process of producing the Co–Cr–Al–Y–Si powder with 40–100 mm particles has been developed. This process yields 70% of this powder fraction, while other existing processes provide 50–60%. The proposed process involves melting of ingots in an electron-beam unit and their subsequent fragmentation using a press and strip rolling mill. It is shown that energy consumption is lower during this mechanical grinding compared to the use of crushers and mills and is almost 20 times higher in atomization. The developed process is waste-free: 40 μm powder fraction is remetled in the ingot production process. The method of producing the Co–Cr–Al–Y–Si powder has been patented. The powder is used as a heat-resistant sublayer of thermal protection coatings for blades of gas turbine engines.

Similar content being viewed by others

References

Yu. A. Litvenyuk, M. I. Grechanyuk, and D. F. Chernega, “Modern methods for smelting heat-resistant alloys for coatings,” Nauk. Visti NTUU KPI, No. 6, 75–79 (2007).

Yu. V. Latash, G. F. Torkhov, and V. K. Granovskii, “Studying arc plasma skull melting,” Probl. Spets. Élektrometall., No. 4, 31–38 (1998).

B. E. Paton, B. I. Medovar, and L. B. Medovar, “Potentialities of electroslag remelting in the production of intermetallics,” Probl. Spets. Élektrometall., No. 1, 9–10 (1998).

S. Mrowec and T. Werber, Modern Heat-Resistant Materials [Russian translation], Metallurgiya, Moscow (1986), p. 360.

Thermal Spray Facilities: Automatic Systems for HVOF, Plasma, Flame Spray, Arc Spray, and Rod Spray, Metallizing Equipment Company, http://www.mecpl.com.

Li Chang-Jiu and Li Wen-Ya, “Effect of sprayed powder particle size on the oxidation bexavior of MCrAlY materials during high velocity oxygen-fuel deposition,” Surf. Coat. Technol., 162, 31–41 (2002).

D. Seo, K. Ogawa, T. Shoji, and S. Murata, Effect of Particle Size Range on Thermally Grown Oxide Scale Formation on Vacuum Plasma Sprayed CoNi- and CoCrAlY Coatings,

http://asm.confex.com/data/manuscript/asm/itsc07/paper15657_manuscript_794_0.pdf.

C. T. Sims and N. S. Stoloff, Superalloys [Russian translation], Part 2, Metallurgiya, Moscow (1995), p. 384.

S. S. Naboichenko (ed.), Powders of Nonferrous Metals [in Russian], Metallurgiya, Moscow (1997), p. 540.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Poroshkovaya Metallurgiya, Vol. 51, No. 11–12 (488), pp. 18–25, 2012.

Rights and permissions

About this article

Cite this article

Grechanyuk, N.I., Gogaev, K.A. & Zatovskii, V.G. Production of Co–Cr–Al–Y–Si powder alloys. Powder Metall Met Ceram 51, 633–638 (2013). https://doi.org/10.1007/s11106-013-9479-9

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11106-013-9479-9