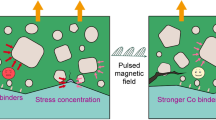

The influence of magnetic treatment on fracture of the WC–Co detonation-sprayed coating–St3 steel substrate system is studied in bending tests. It is established that magnetic treatment leads to the redistribution of elements at the coating–substrate interface. It is shown that magnetic treatment improves the mechanical properties of the coating–substrate system: plastic strain of the system increases from 0.15% to 0.35% when coating starts cracking and stresses developed at fracture increase from 700 to 1300 MPa. The improvement of properties is due to better adhesion at the coating–substrate interface resulting from diffusion-controlled redistribution of elements during magnetic treatment.

Similar content being viewed by others

References

L. A. Chebotkevich, A. A. Urusovskaya, and V. V. Veter, Kristallografiya, 10, No. 4, Issue 2, 688 (1965).

L. A. Chebotkevich, A. A. Urusovskaya, V. V. Veter, and A. D. Ershov, “Interaction of Bloch surfaces with dislocations in weak fields,” Fiz. Tverd. Tela, 9, No. 4, 1093–1097 (1967).

S. Hayashi, S. Takahashi, and M. Yamamoto, “Plastic deformation of nickel single in an alternating magnetic field,” J. Phys. Soc. Jpn., 25, 910 (1968).

S. Hayashi, S. Takahashi, and M. Yamamoto, “Magneto-plastic effect in nickel single crystals,” J. Phys. Soc. Jpn., 30, No. 2, 381–387 (1971).

S. Hayashi, S. Takahashi, and M. Yamamoto, “Magneto-plastic effect in nickel and nickel-cobalt alloy single crystals,” J. Phys. Soc. Jpn., 32, No. 4, 949–957 (1972).

S. Hayashi, S. Takahashi, and M. Yamamoto, “Effect of an alternating magnetic field on the flow stress of Ni and Ni–Co,” Phys. Lett., 42, 171–172 (1972).

E. L. Frankevich, V. I. Lesin, and A. I. Pristupa, “Spin-dependent reactions between structural defects and their effect on the plasticity of crystals in the magnetic field,” Pis’ma Zh. Éksp. Teor. Fiz., 75, Issue 2 (8), 415–427 (1978).

Yu. I. Golovin, “Magnetic plasticity of solids,” Fiz. Tverd. Tela, 46, No. 5, 769–803 (2004).

V. E. Oliker, T. Ya. Gridasova, V. L. Sirovatka, et al., “Effect of magnetic abrasive treatment on hightemperature oxidation of NiAl and NiAl–Re coatings,” Powder Metall. Met. Ceram., 48, No. 7–8, 466–477 (2009).

V. E. Oliker, E. N. Eliseeva, T. Ya. Gridasova, et al., “Effect of magnetic treatment on the microstructure of NiAl–Re alloy,” Powder Metall. Met. Ceram., 49, No. 3–4, 245–252 (2010).

V. E. Oliker, T. Ya. Gridasova, I. I. Timofeeva, et al., “Effect of magnetic treatment on the microstructure and abrasive resistance of WC–Co detonation-sprayed coatings,” Powder Metall. Met. Ceram., 51, No. 5–6, 345–352 (2012).

M. A. Verzhakovskaya, Heterodiffusion of Aluminum in Iron in Pulsed Magnetic Field [in Russian], Author’s Abstract of PhD Thesis, Samara (2007).

G. V. Spivak, R. V. Telesnin, I. S. Kolotov, et al., Break of Domain Walls in Ferromagnetic Materials under Magnetic Fields [in Russian], http://ross-nauka.narod.ru/06/06-159.html (1970).

L. I. Tushinskii and A. V. Plokhov, Studying the Structure and Mechanical Properties of Coatings [in Russian], Nauka, Novosibirsk (1986), p. 198.

Yu. N. Podrezov, Ya. I. Evich, and N. P. Korzhova, “Fracture toughness of coatings from a eutectic alloy based on L12 intermetallic in the Al–Ti–Cr ternary system,” Élektron. Microsc. Prochn. Mater., Issue 128, 93–99 (2007).

J. F. Knott, Fundamentals of Fracture Mechanics, John Wiley–Halsted Press, New York (1973).

T. P. Shmyreva and G. M. Vorob’ev, “X-ray determination of macrostreses in coatings,” Probl. Prochn., No. 8, 71–73 (1983).

V. A. Barvinok and V. I. Bogdanovich, “Calculation of residual stresses in plasma-deposited coatings considering growing process,” Fiz. Khim. Obrab. Mater., No. 4, 95–100 (1981).

I. M. Fedorchenko, E. I. Ischchenko, and A. I. Bezykornov, “Residual stresses in plasma-deposited coatings,” Zashch. Pokr. Met., Issue No. 14, 55–57 (1980).

Author information

Authors and Affiliations

Corresponding author

Additional information

Deceased (V. E. Oliker and T. Ya. Gridasova).

Translated from Poroshkovaya Metallurgiya, Vol. 51, No. 7–8 (486), pp. 136–144, 2012.

Rights and permissions

About this article

Cite this article

Oliker, V.E., Podrezov, Y.N., Yarmatov, I.T. et al. Effect of magnetic treatment on the microstructure and strength of WC–Co detonation-sprayed coatings. Powder Metall Met Ceram 51, 485–490 (2012). https://doi.org/10.1007/s11106-012-9458-6

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11106-012-9458-6