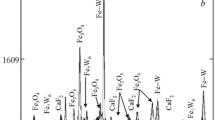

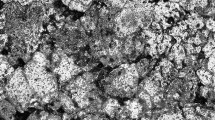

The paper examines the tribological characteristics of a Fe–W–CaF2 composite antifriction material (CAM) in combination with 65G steel during dry friction in air at a high sliding velocity (15 m/sec) and insignificant (0.64–1.28 MPa) pressures. It is established that with twofold increase in pressure (from 0.64 to 1.28 MPa), CAM friction coefficient decreases from 0.25 to 0.20 (by 20%) and wear increases from 0.0158 to 0.03085 mg/km (by 49%) but remains insignificant. The factors acting in the friction process lead to the formation of secondary lubricating films. They prevent mechanical contact between the rubbing surfaces and provide necessary antifriction and operating properties. It is shown that the secondary lubricating films as thin layers with inclusions of solid lubricants differ from the starting material in chemical and phase composition, structural state, and better mechanical characteristics.

Similar content being viewed by others

References

I. M. Fedorchenko and L. I. Pugina, Sintered Composite Antifriction Materials [in Russian], Naukova Dumka, Kiev (1980), p. 440.

V. N. Miroshnikov and Yu. F. Shevchuk, “Choice of solid lubricants,” Powder Metall. Met. Ceram., 10, No. 11, 911–915 (1971).

Okage Sai and Okage Masahiko, Complex Materials Resistant to High-Temperature Oxidation in Air Containing Fluorides as Lubricants [Russian translation], Japan Patent 48-17684, Publ. 31 May (1973).

I. M. Fedorchenko, Yu. F. Shevchuk, and V. N. Miroshnikov, Antifriction Iron-Based Metal Ceramics [in Russian], USSR Inventor’s Certificate No. 433234, Bulletin No. 23, Publ. (1974).

L. I. Pugina, I. M. Fedorchenko, et al., Sintered Antifriction Nickel-Based Material [in Russian], USSR Inventor’s Certificate No. 456015, Bulletin No. 1, Publ. (1975).

I. M. Fedorchenko, V. D. Zozulya, and Yu. F. Shevchuk, “Lubricating properties of calcium fluoride,” Powder Metall. Met. Ceram., 9, No. 10, 818–820 (1970).

I. L. Knunyants et al. (ed.), Great Russian Encyclopedia: Chemical Encyclopedia (in 5 Vols.) [in Russian], Moscow (1992), Vol. 3, p. 639.

Antifriction Powder Materials. Method of Determining Tribotechnical Properties, GOST 26614–85 [in Russian], Goskomstandart, Moscow (1985), p. 9.

S. M. Firstov, V. F. Gorban’, É. P. Pechkovskii, and N. A. Mameka, “Indentation equation,” Dop. NAN Ukrainy, No. 12, 100–106 (2007).

A. G. Kostornov, Yu. M. Simeonova, O. I. Fushchich, et al., “Defining influence of the tribosynthesis of new structures in the friction area on the service properties of antifriction materials,” in: Friction and Wear Friction (Collected Scientific Papers) [in Ukrainian], Issue No. 46, NAU, Kiev (2006), pp. 84–94.

A. G. Kostornov, Yu. M. Simeonova, O. I. Fushchich, et al., “Effect of factors governing dry friction on structure formation for the tribological synthesis zone in composites based on copper,” Powder Metall. Met. Ceram., 45, No. 3–4, 118–123 (2006).

A. G. Kostornov, O. I. Fushchich, T. M. Chevychelova, et al., “Friction, wear, and targeted synthesis of rubbing surfaces of self-lubricating composites,” Powder Metall. Met. Ceram., 46, No. 3–4, 111–117 (2007).

A. G. Kostornov, O. I. Fushchich, V. F. Gorban’, et al., “Dependence of antifriction properties of self-lubricating copper-based composite on the elastoplastic characteristics of tribosynthesis region,” Powder Metall. Met. Ceram., 47, No. 11–12, 674–679 (2008).

A. G. Kostornov, O. I. Fushchich, T. M. Chevychelova, et al., “Structural and phase transformations in the tribosynthesis area of copper-based self-lubricating composite material,” Powder Metall. Met. Ceram., 48, No. 5–6, 358–364 (2009).

I. V. Kragel’skii, Friction and Wear [in Russian], Mashinostroenie, Moscow (1968), p. 478.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Poroshkovaya Metallurgiya, Vol. 51, No. 7–8 (486), pp. 48–58, 2012.

Rights and permissions

About this article

Cite this article

Kostornov, A.G., Fushchich, O.I., Gorban, V.F. et al. Effect of dry friction parameters on the tribosynthesis of secondary structures on composite antifriction iron-based material. Powder Metall Met Ceram 51, 412–419 (2012). https://doi.org/10.1007/s11106-012-9449-7

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11106-012-9449-7