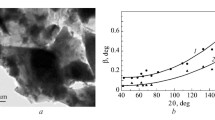

Heating elements with a resistive layer composed of Si3N4 and 13.5 vol.% ZrC with an average grain size varying from 1 to 46 μm are produced by hot pressing. The phase and grain-size composition and morphology of zirconium carbide grains are examined with X-ray diffraction, sedimentation analysis, and scanning electron microscopy. Microstructural images of the hot-pressed composites are taken with an optical microscope. Direct current resistivity is studied by voltmeter–ammeter method in the temperature range between 20 and 600°C. Different types of structure may form at different dielectric–conductor diameter ratios. These structures considerably differ in resistivity. The resistivity of the composites depends on the specific surface area of the conductive particles and effective cross-sectional area of the conductive cluster (resistivity increases by one order of magnitude with transition from statistical to matrix structure). It is shown that the structure and resistivity can be controlled by introducing a bimodal mixture of coarse and fine conductive particles. The matricity of the composite is evaluated by measuring its resistivity.

Similar content being viewed by others

References

V. Ya. Petrovsky and Z. S. Rak, “Densification, microstructure and properties of electroconductive Si3N4–TaN composites. Part II: Electrical and mechanical properties,” J. Eur. Ceram. Soc., 21, No. 2, 237–244 (2001).

J. L. Huang, S. Y. Chen, and M. T. Lee, “Microstructure, chemical aspects and mechanical properties of TiB2/Si3N4 and TiN/Si3N4 composites,” J. Mater. Res., 9, No. 9, 2349–2354 (1994).

A. Yu. Dovzhenko and V. A. Bunin, “Effect of the shape and size of conducting phase particles on the formation of a percolation cluster in a ceramic composite,” Zh. Tekh. Fiz., 3, No. 8, 123–125 (2003).

V. Ya. Petrovskii, “Use of conducting composites based on Si3N4 in broadband electric heaters. I. Fabrication of the functional element,” Powder Metall. Met. Ceram., 37, No. 3–4, 174–181 (1998).

V. Ya. Petrovskii, “Use of conducting composites based on Si3N4 in broadband electric heaters. II. Energy characteristics of an all-ceramic heater,” Powder Metall. Met. Ceram., 37, No. 5–6, 291–297 (1998).

V. Ya. Petrovskii, “Application of conducting Si3N4 composites in wide-range electric radiators. III. Load life of ceramic radiators,” Powder Metall. Met. Ceram., 37, No. 7–8, 386–389 (1998).

Kyocera Group, www.global.kyocera.com/prdct/fc/product/usage/heater/index.html.

Y. G. Gogotsi, “Review: particulate silicon nitride based composite,” J. Mater. Sci., 29, No. 10, 2541–2556 (1994).

Z. Yao, J. Stiglich, and T. S. Sudarshan, “Molybdenum silicide based materials and their properties,” J. Mater. Eng. Perform., 8, No. 3, 291–304 (1999).

S. Köbel, J. Pluschke, U. Vogt, and T. J. Graule, “MoSi2–Al2O3 electroconductive ceramic composites,” Ceram. Int., 30, No. 8, 2105–2110 (2004).

W. W. Wu, G. J. Zhang, Y. M. Kan, and P. L. Wang, “Reactive hot pressing of ZrB2–SiC–ZrC ultra high-temperature ceramics at 1800°C,” J. Am. Ceram. Soc., 89, No. 9, 2967–2969 (2006).

G. Blugan, M. Hadad, J. Janszak-Rusch, et al., “Microstructure, mechanical properties and fractography of commercial silicon nitride-titanium nitride composites for wear applications,” J. Am. Ceram. Soc., 88, No. 4, 926–933 (2005).

V. V. Skorokhod, “Theory of the physical properties of porous and composite materials and the principles for control of their microstructure in manufacturing processes,” Powder Metall. Met. Ceram., 34, No. 1–2, 48–63 (1995).

A. S. Skal, “Topology of a two-component disordered system below and above the percolation threshold,” Phil. Mag. B, 45, No. 3, 335–346 (1982).

M. Ambrožic, A. Dakskobler, and M. Valant, “Numerical analysis of steric influence on conductivity percolation threshold,” Eur. Phys. J. Appl. Phys., 30, No. 1, 23–31 (2005).

A. B. Khanikaev, A. B. Granovskii, and J. P. Clerc, “Influence of the size distribution of granules and of their attractive interaction on the percolation threshold in granulated alloys,” Phys. Sol. State, 44, No. 9, 1537–1539 (2002).

M. Ambrožic and A. Dakskobler, “Some aspects of numerical analysis of conductivity percolation threshold,” J. Eur. Ceram. Soc., 27, No. 2–3, 541–544 (2007).

S. A. Bagnich and A. V. Konash, “Effect of inhomogeneous properties of the system on two-dimensional process,” Fiz. Tverd. Tela, 43, No. 12, 2215–2222 (2001).

N. F. Uvarov, “Estimation of composites conductivity using a general mixing rule,” Solid State Ionics, 136, 1267–1272 (2000).

C. M. Mari and G. Dotelli, “How to forecast the electrical behavior of ionic conductor composites?” J. Math. Sci., 36, No. 5, 1141–1147 (2001).

D. S. McLachlan, M. Blaszkiewicz, and R. E. Newnham, “Electrical resistivity of composites,” J. Am. Ceram. Soc., 73, No. 8, 2187–2203 (1990).

V. Petrovsky, “Electrical response on microstructure evolution of multicomponent ceramic matrix materials,” J. Mat. Sci. Eng., 4, No. 2, 39–51 (2010).

V. Ya. Petrovskii and V. V. Skorokhod, “Physical principles and technological aspects of the production of gradient composites based on an oxygen-free ceramics,” Powder Metall. Met. Ceram., 38, No. 3–4, 115– 125 (1999).

G. G. Gnesin, V. M. Kirilenko, and V. Ya. Petrovskii, “Quality control of hot-pressed silicon nitride dielectric materials,” Powder Metall. Met. Ceram., 21, No. 3, 204–208 (1982).

G. V. Samsonov, Nitrides [in Russian], Naukova Dumka, Kiev (1969), p. 380.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Poroshkovaya Metallurgiya, Vol. 51, No. 5–6 (485), pp. 73–83, 2012.

Rights and permissions

About this article

Cite this article

Brodnikovska, I.V., Soltis, M.V., Kirilenko, K.V. et al. Effect of the particle size of conductive inclusions on the structurization and resistivity of Si3N4–ZrC ceramics. Powder Metall Met Ceram 51, 307–315 (2012). https://doi.org/10.1007/s11106-012-9433-2

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11106-012-9433-2