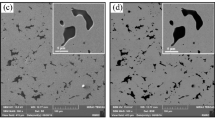

The effect of boron additives on the structure, magnetic properties, and corrosion resistance of Ni– P-clad iron-based soft magnetic materials is studied. The iron powder (with a particle size of 250 to 350 μm) is clad with nickel–phosphorus through thermochemical reduction of nickel chloride by sodium hypophosphite, and boron (1 and 3 wt.%) is added to activate the formation of a liquid phase during high-temperature sintering and reduce the porosity of the prepared composites. It is shown that the cladding of iron powder with nickel–phosphorus increases its corrosion resistance by two points on the scale of ISO 11130:2010 and decreases the depth corrosion index from 0.6457 mm/year to 0.0269 mm/year, which is likely due to the high corrosion resistance of the nickel-phosphorus coating. Moreover, the cladding of iron powder with nickel–phosphorus substantially decreases (2–2.5 times) the magnetic loss in ac fields at a frequency of 50 Hz. The microstructure of the Fe–Ni–P–B composites with different boron contents is heterophase and consists of iron-based ferritic grains, pores, and a liquid phase based on the γ-Fe + Fe2B, α-Fe + Fe3P, and Ni + Ni3B eutectics. The boron content of the material should not exceed 1% because a decrease in the volume of the ferromagnetic component reduces the magnetic induction and permeability. The addition of boron to the clad iron powder increases the hardness and strength of the material produced.

Similar content being viewed by others

References

Y. Shimada, “Development of high performance sintered soft magnetic material,” Powder Metall., 53, No. 8, 686–6952 (2006).

J. A. Bas, J. A. Calero, and M. J. Dougan, “Sintered soft magnetic materials. Properties and applications,” J. Magn. Magn. Mat., 254–255, 391–398 (2003).

A. Kunevich and A. Maksimov, “Modern soft magnetic materials for power electronics,” Élektronika, No. 4, 32–35 (2008).

M. A. Belen’kii and A. F. Ivanov, Electrodeposition of Metal Coatings [in Russian], Metallurgiya, Moscow (1985), pp. 275.

O. A. Panasyuk, V. A. Maslyuk, H. Danninger, at el., “Origination and investigation of powder magnetic-soft materials, based on the iron powders, clad with metal and non-metal components,” in: Proc. Conf. Euro PM (Austria Centre, October 17–21, 2004), Vol. 4, Austria (2004), pp. 577–583.

V. G. Lyul’ko, V. A. Maslyuk, O. A. Panasyuk, et al., “Preliminary analysis and selection of Fe–P composite powders for making sintered soft magnetic materials,” in: Proc. Int. Sci. Conf. PM, Tonpik, Minsk (2004), pp. 46–48.

I. A. Novokhatskii, V. Z. Kisun’ko, and V. I. Lad’yanov, “Structural transformations in liquid iron and melts on its basis,” Stal’, No. 8, 33–37 (1982).

S. Z. Bokshtein, Structure and Properties of Metal Alloys [in Russian], Metallurgiya, Moscow (1971), p. 496.

Yu. N. Taran and V. I. Mazur, Structure of Eutectic Alloys [in Russian], Metallurgiya, Moscow (1977), p. 312.

V. M. Zalkin, Nature of Eutectic Alloys and Effect of Contact Melting [in Russian], Metallurgiya, Moscow (1987), p. 152.

D. Brandon and W. Kaplan, Microstructural Characterization of Materials, J. Wiley, New York (1999).

System of Image Analysis and Modeling Structures SIAMS 600 [in Russian], SIAMS Ltd. (http://siams.com), Ekaterinburg.

Corrosion of Metals and Alloys. Alternative Testing by Immersion in Salt Solution [in Ukrainian], ISO 11130:2010, Ukrmetrteststandart, Kiev (2010), p. 27.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Poroshkovaya Metallurgiya, Vol. 51, No. 5–6 (485), pp. 3–11, 2012.

Rights and permissions

About this article

Cite this article

Boshitskaya, N.V., Vlasova, O.V., Uvarova, I.V. et al. Effect of boron additives on the structure and properties of soft magnetic composites produced from nickel-clad iron powders. Powder Metall Met Ceram 51, 253–259 (2012). https://doi.org/10.1007/s11106-012-9425-2

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11106-012-9425-2