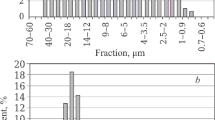

The potential use of a new-type mill developed at the Frantsevich Institute for Problems of Materials Science to produce copper and chromium powder mixtures intended for the manufacture of electrical-grade materials is studied. The mill ensures mechanical grinding of loose materials by mechanisms similar to those acting in vortex and jet mills. The greater powder refinement in this mill is due to the sliding interaction of particles with abrasive surfaces of the mill chamber. It is shown that common grinding of electrolytic copper and reduced or aluminothermic chromium for 10–30 min in argon promotes variation in the shape of particles, facilitates their mixing, and provides uniform distribution of components in the mixture.

Similar content being viewed by others

Notes

The samples were dynamically pressed by A. V. Laptev using equipment developed at the Frantsevich Institute for Problems of Materials Science.

References

L. Peng, X. Mao, K. Xu, and W. Ding, “Property and thermal stability of in situ composite Cu–Cr alloy contact cable,” J. Mater. Process. Technol., 166, No. 2, 193–198 (2005).

P. G. Slade, “Advances in material development for high power, vacuum interrupter contacts,” IEEE Trans. Compon. Packag. Manuf. Technol. Part A, 17, No. 1, 96–106 (1994).

E. V. Khomenko, A. V. Laptev, A. I. Tolochin, et al., “Structure and properties of Cr–Cu composites of various composition produced by solid-phase sintering in vacuum,” in: Electrical Contacts and Electrodes (Collected Scientific Papers) [in Russian], Inst. Probl. Materialoved. NAN Ukrainy, Kiev (2008), pp. 110– 115.

I. I. Kornilov and V. V. Glazova, Interaction of Refractory Metals of Transition Groups with Oxygen [in Russian], Nauka, Moscow (1967), p. 225.

T. E. Tietz and J. W. Wilson, Behavior and Properties of Refractory Metals, Arnold Publishing Co, London (1965).

G. G. Gnesin (ed.), Sintered Materials for Electrical Engineering and Electronics: Handbook [in Russian], Metallurgiya, Moscow (1981), p. 343.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Poroshkovaya Metallurgiya, Vol. 51, No. 3–4 (484), pp. 12–18, 2012.

Rights and permissions

About this article

Cite this article

Khomenko, O.V., Naida, Y.I. & Minakova, R.V. Analyzing the quality of grinding and mixing of copper and chromium powders in a new-type mill. Powder Metall Met Ceram 51, 137–141 (2012). https://doi.org/10.1007/s11106-012-9408-3

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11106-012-9408-3