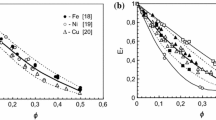

A continuum model based on the physical hypotheses of the discrete contact model is developed to describe the elastic and plastic properties of isotropic powder materials, taking into account the inhomogeneous deformation of the solid phase. The localization of elastic and plastic deformation is described by hypothesizing that deformable and nondeformable volumes form in the solid phase and that the resistance to deformation is associated only with the deformable volume. An analytical dependence of the deformable volume on the density of powder material is provided. The proposed model ensures high-accuracy fit to the experimental compaction curves at the stages of interparticle slip and plastic deformation of particles. At the beginning of plastic deformation, a particle is regarded as a cast one already plastically deformed and hardened to the level of the effective yield strength of the solid phase. The particle is further hardened as a cold-worked cast material is. Good agreement is reached between calculated and experimental data on the elastic moduli and plastic compaction of powders during isostatic pressing and deposition in a high-pressure chamber.

Similar content being viewed by others

References

V. V. Skorokhod, Rheology-Based Theory of Sintering [in Russian], Naukova Dumka, Kiev (1975), p. 151.

V. V. Skorokhod and L. I. Tuchinskii, “Condition of plasticity of porous bodies,” Powder Metall. Met. Ceram., 17, No. 11, 880–883 (1978).

A. K. Grigor’ev and A. I. Rudskoi, Deformation and Compaction of Powder Materials [in Russian], Metallurgiya, Moscow (1992), p. 192.

M. Yu. Bal’shin, Scientific Basis of Powder and Fiber Metallurgy [in Russian], Metallurgiya, Moscow (1972), p. 336.

A. L. Gurson, “Continuum theory of ductile rupture by void nucleation and growth: Part I. Yield criteria and flow rules for porous ductile materials,” Teor. Osn. Inzh. Rasch., No. 1, 1–16 (1975).

Ya. E. Beigel’zimer and A. P. Get’manskii, “A model of the development of plastic deformation of porous solids in the percolation theory approximation,” Powder Metall. Met. Ceram., 27, No. 10, 773–776 (1988).

E. V. Lomakin and Yu. N. Rabotnov, “Elastic relations for an isotropic bi-modulus body,” Mekh. Tverd. Tela, No. 6, 29–34 (1978).

A. F. Fedotov and P. I. Krasnoshchekov, “Model of plastic deformation of powder materials taking account of the proportion of contact volume,” Powder Metall. Met. Ceram., 44, No. 9–10, 420–425 (2005).

M. Oyane, S. Shima, and Y. Kono, “Theory of plasticity for porous metals,” Bull. JSME, 16, No. 99, 1254–1262 (1973).

A. F. Fedotov and P. I. Krasnoshchekov, “Calculating the effective elastic moduli of isotropic powder materials,” in: Proc. All-Rus. Sci. Conf. on Mathematical Modeling and Boundary-Value Problems, Part 1 [in Russian] (May 29–31, 2007), SamGTU, Samara (2007), pp. 262–265.

M. S. Koval’chenko, “Mechanical properties of isotropic porous materials. I. Elastic and rheological properties,” Powder Metall. Met. Ceram., 32, No. 3, 268–273 (1993).

G. S. Pisarenko, V. T. Troshchenko, and A. Ya. Krasovskii, “Investigation of the mechanical properties of porous iron in tension and torsion. Communication 2,” Powder Metall. Met. Ceram., 4, No. 7, 587–592 (1965).

A. P. Amosov and A. F. Fedotov, “Variant of the plasticity condition for powdered solids,” Powder Metall. Met. Ceram., 39, No. 3–4, 116–121 (2000).

Ya. E. Beigel’zimer, A. P. Getmanskii, and L. I. Alistratov, “Plasticity condition for hard-metal mixture powders,” Powder Metall. Met. Ceram., 25, No. 12, 952–956 (1986).

A. M. Dmitrieva and A. G. Ovchinnikova (eds.), Advanced Processes and Equipment for Forging Powder Parts [in Russian], Mashinostroenie, Moscow (1991), p. 320.

V. V. Skorokhod, M. B. Shtern, and I. F. Martynova, “Theory of nonlinearly viscous and plastic behavior of porous materials,” Powder Metall. Met. Ceram., 26, No. 8, 621–626 (1987).

N. V. Andreeva, I. D. Radomysel’skii, and N. I. Shcherban’, “Compressibility of powders,” Powder Metall. Met. Ceram., 14, No. 6, 457–464 (1975).

N. F. Kunin and B. D. Yurchenko, “Net compaction pressure of metal powders,” Powder Metall. Met. Ceram., 7, No. 8, 604–609 (1968).

N. F. Kunin, B. D. Yurchenko, and N. V. Myshkina, “Energy relations in the compaction of binary powder mixtures,” Powder Metall. Met. Ceram., 7, No. 9, 688–692 (1968).

M. Yu. Bal’shin and S. S. Kiparisov, Fundamentals of Powder Metallurgy [in Russian], Metallurgiya, Moscow (1978), p. 184.

I. F. Martynova, “Physics of the plastic deformation of porous bodies,” in: Rheological Models and Deformation of Porous, Powder, and Composite Materials [in Russian], Naukova Dumka, Kiev (1985), pp. 98–105.

A. V. Tret’yakov and V. I. Zyuzin, Mechanical Properties of Metals and Alloys Subject to Plastic Working [in Russian], Metallurgiya, Moscow (1973), p. 224.

Acknowledgement

The study was performed in line with the analytic departmental purpose-oriented program “Development of the Scientific Potential of Higher School (2009–2010)” (Project No. 2.1.2/1431).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Poroshkovaya Metallurgiya, Vol. 50, No. 5–6 (479), pp. 67–82, 2011.

Rights and permissions

About this article

Cite this article

Fedotov, A.F. Elastic and plastic properties of powder materials: a continuum model. Powder Metall Met Ceram 50, 301–312 (2011). https://doi.org/10.1007/s11106-011-9333-x

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11106-011-9333-x