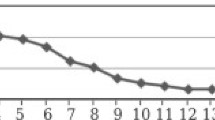

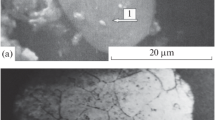

The production of powder alloy AD33 containing additional 1% Fe is examined. The structurization and properties of the powders and alloys formed under high-pressure water atomization are analyzed. There is a complex dependence of the particle size and nature of oxide films on their surface on the melt temperature, which has to be no more than 900°C. The strength of the powder alloy compacted under different conditions increases by 60–70% as compared with the conventional alloy (without iron) and corresponds to the strength of high-alloy aluminum alloys.

Similar content being viewed by others

References

Metallurgy and Metallography of Nonferrous Metals. To the 80thBirth Anniversary of Academician A. A. Bochvar [in Russian], Nauka, Moscow (1982), p. 248.

Yu. V. Mil’man, “New high-strength aluminum alloys,” in: Pressing Problems of Modern Materials Science (in 2 vols.), Vol. 1 [in Russian], Akademperiodika, Kiev (2008), pp. 597–612.

A. G. Kostornov, Materials Science of Fine and Porous Metals and (in 2 vols.), Vol. 1 [in Russian], Naukova Dumka, Kiev (2002), p. 573.

V. G. Gopienko, V. P. Cherepanov, and E. A. Savchenko, “New processes of producing powder parts from aluminum and its alloys,” Tsvet. Met., No. 2, 10–15 (1991).

A. F. Sanin, E. A. Dzhur, and S. A. Bozhko, “Predicting the particle size of melt-atomized metal powders,” Kosm. Nauka Tekhnol., 10, No. 1, 79–82 (2004).

I. S. Miroshnichenko, Melt Quenching [in Russian], Metallurgiya, Moscow (1982), p. 176.

A. S. Drachinskii, A. V. Krainikov, and G. F. Sarzhan, “Structure and strength of powder metallurgy aluminum alloy AK-6,” Powder Metall. Met. Ceram., 37, No. 3–4, 145–148 (1998).

K. V. Levochko, A. F. Lednyanskii, and A. F. Sanin, “Studying the particle shape of atomized powders made of iron-doped aluminum alloy,’ in: Proc. 7th Int. Conf. Equipment and Processes of Thermal Treatment of Metals and Alloys [in Russian], Vol. 2, National Scientific Center Kharkov Fiz. Tekh. Inst., Kharkov (2006), pp. 118–121.

O. S. Nichiporenko, A. V. Pomosov, and S. S. Naboinichenko, Copper Powders and Alloys [in Russian], Metallurgiya, Moscow (1988), p. 206.

Yu. F. Ternovoi, S. S. Kudievskii, and N. N. Pashetneva, Engineering Calculations of Molten Metal Atomization Processes [in Russian], Izd. Zaporozh. Gos. Inzh. Akad., Zaporozh’e (2005), p. 149.

A. F. Sanin and O. S. Nichiporenko, “Effect of water pressure on the particle shape of powder in atomization,” Powder Metall., Met. Ceram., 27, No. 9, 677–680 (1988).

K. V. Bechke, A. F. Sanin, and A. F. Lednyanskii, “Physical and chemical processes in water atomization of aluminum alloys,” in: Proc. Int. Conf. HighMatTech, Kiev (2009), p. 399.

K. V. Levochko and S. A. Shcherbina, “Predicting the properties of atomized alloy powders with different melting temperatures,” Visn. Mizhnar. Slov. Univ., Ser. Tekh. Nauki, 11, No. 1, 7–11 (2008).

K. V. Levochko and A. F. Sanin, “Effect of production conditions on the grain-size composition of wateratomized aluminum alloy powders,” Visn. Dnipropetr. Univ., 2, No. 10, 82–86 (2006).

K. V. Levochko and A. F. Lednyanskii, “Studying the formation of hydroxide films on water-atomized aluminum powders,” Kosm. Nauka Tekhnol., 11, No. 1, 48–50 (2005).

A. K. Lokenbakh, V. V. Strod, and N. V. Nekrasova, “Initial oxidation of highly-dispersed aluminum,” Izv. AN LatvSSR, No. 5, 627–628 (1984).

J. E. Hatch, Aluminum: Properties and Physical Metallurgy, ASM, Metals Park, Ohio (1984).

M. M. Myshlyaev, “Structure, phase state, and high-speed superplasticity of Al–Li nanostructured alloys after severe plastic deformation,” in: Proc. 5th Int. Conf., Materials and Coatings in Extreme Conditions: Research, Application, Pollution-Free Production and Disposal of Products (September 22–26, 2008, Bol’shaya Yalta, Zhukovka, Crimea) [in Russian], Inst. Probl. Materialoved. NAN Ukrainy, Kiev (2008), p. 176.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Poroshkovaya Metallurgiya, Vol. 49, No. 5–6 (473), pp. 19–27, 2010.

Rights and permissions

About this article

Cite this article

Bechke, K.V., Sanin, A.F. Structure and properties of water-atomized aluminum powder alloy. Powder Metall Met Ceram 49, 266–271 (2010). https://doi.org/10.1007/s11106-010-9232-6

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11106-010-9232-6