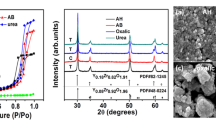

Uniformly dispersed yttrium aluminum garnet (Y3Al5O12, YAG) ultrafine powders are synthesized by coprecipitating a mixed solution of aluminum and yttrium nitrates with ammonium hydrogen carbonate in the presence of sodium dodecyl sulfate (SDS) as a dispersing agent. The primary purpose of introducing SDS is to protect YAG particles from agglomeration. The evolution of phase composition and microstructure of the as-synthesized YAG powders are characterized by thermogravimetry/differential scanning calorimetry, X-ray diffraction, infrared spectra, and scanning electron microscopy. The results show that phase-pure YAG powders can be achieved by calcination of the precursor at 900°C for 2 h. Uniformly dispersed YAG powders with a particle size of approximately 90–100 nm are obtained with the optimum molar ratio of Al3+ to SDS of 2, and excessive SDS restrains good dispersion of the YAG powders. The dispersion mechanism of SDS in the preparation process is discussed.

Similar content being viewed by others

References

B. Cockayne, “The uses and enigmas of the Al2O3–Y2O3 phase synthesis,” J. Less-Common Met., 144, 199–206 (1985).

T. A. Parthasarathy, T. Mah, and K. Keller, “High-temperature deformation, behavior of polycrystalline yttrium aluminum garnet (YAG),” Ceram. Eng. Sci. Proc., 12, 1767–1773 (1991).

J. G. Li, T. Ikegami, J. H. Lee, et al., “Reactive yttrium aluminate garnet powder via co-precipitation using ammonium hydrogen carbonate as the precipitant,” J. Mater. Res., 15, 1864–1867 (2000).

A. Ikesue, T. Kinoshita, K. Kamata, and K. Yoshida, “Fabrication and optical properties of highperformance polycrystalline Nd:YAG ceramics for solid-state lasers,” J. Am. Ceram. Soc., 78, 1033–1040 (1995).

J. R. Lu, J. H. Lu, T. Murai, et al., “Development of Nd : YAG ceramic lasers,” Adv. Sol.-St. Lasers., 68, 507–517 (2002).

J. R. Lu, K. Ueda, H. Yagi, et al., “Neodymium doped yttrium aluminum garnet (Y3Al5O12) nanocrystalline ceramics—a new generation of solid state laser and optical materials,” J. All. Compd., 341, 220–225 (2002).

J. R. Lu, M. Prabhu, J. Song, and C. Li, “Optical properties and highly efficient laser oscillation of Nd : YAG ceramics,” Appl. Phys., B71, 469–473 (2000).

D. Messier and G. Gazza, “Synthesis of MgAl2O4 and Y3Al5O12 by thermal decomposition of hydrated nitrate mixtures,” Am. Ceram. Soc. Bull., 51, 692–697 (1972).

Y. G. Wang, L. G. Zhang, Y. Fan, et al., “Synthesis, characterization and optical properties of pristine and doped yttrium aluminum garnet nanopowders,” J. Am. Ceram. Soc., 88, 284–286 (2005).

J. Su, Q. L. Zhang, C. J. Gu, et al., “Preparation and characterization of Y3Al5O12 (YAG) nanopowder by co-precipitation method,” Mater. Res. Bull., 40, 1279–1285 (2005).

C. C. Chiang, M. S. Tsai, C. S. Hsiao, and M. H. Hon, “Synthesis of YAG : Ce phosphor via different aluminum sources and precipitation processes,” J. All. Compd., 416, 265–269 (2006).

Y. T. Nien, Y. L. Chen, I. G. Chen, et al., “Synthesis of nanoscaled yttrium aluminum garnet phosphor by co-precipitation method with HMDS treatment,” Mater. Chem. Phys., 93, 79–83 (2005).

S. H. Tong, T. C. Lu, and W. Guo, “Synthesis of YAG powder by alcohol–water co-precipitation method,” Mater. Lett., 61, 4287–4289 (2007).

S. Ramanathan, S. K. Roy, and Y. J. Bhat, “Transparent YAG from powder prepared by homogeneous precipitation reaction-Al(NO3)3 + Y(NO3)3 + (NH4)2SO4 + CO(NH2)2,” J. Mater. Sci. Lett., 20, 2119–2121 (2001).

N. Matsushita, N. Tsuchiya, K. Nakatsuka, and T. Yanagitani, “Precipitation and calcination processes for yttrium aluminum garnet precursors synthesized by the urea method,” J. Am. Ceram. Soc., 82, 1977–1984 (1999).

Q. M. Lu, W. S. Dong, H. J. Wang, et al., “A novel way to synthesize yttrium aluminum garnet from metal–inorganic precursors,” J. Am. Ceram. Soc., 85, 490–492 (2002).

P. Vaqueiro and M. A. López-Quintela, “Synthesis of yttrium aluminum garnet by the citrate gel process,” J. Mater. Chem., 8, 161–163 (1998).

M. B. Kakade, S. Ramanathan, and S. K. Roy, “Synthesis of YAG powder by aluminum nitrate–yttrium nitrate-lycine reaction,” J. Mater. Sci. Lett., 21, 927–929 (2002).

S. A. Hassanzadeh-Tabrizi, E. Taheri-Nassaj, and H. Sarpoolaky, “Synthesis of an alumina–YAG nanopowder via sol–gel method,” J. All. Compd., 456, 282–285 (2008).

X. D. Zhang, H. Liu, W. He, et al., “Novel synthesis of YAG by solvothermal method,” J. Cryst. Growth, 275, 1913 –1917 (2005).

K. Y. Jung, D. Y. Lee, and Y. C. Kang, “Morphology control and luminescent property of Y3Al5O12 : Tb particles prepared by spray pyrolysis,” Mater. Res. Bull., 40, 2212–2218 (2005).

J. Marchal, T. John, R. Baranwal, et al., “Yttrium aluminum garnet nanopowders produced by liquid-feed flame spray pyrolysis (LF-FSP) of metalloorganic precursors,” Chem. Mater., 16, 822–831 (2004).

F. G. Qiu, X. P. Pu, J. Li, et al., “Thermal behavior of the YAG precursor prepared by sol–gel combustion process,” Ceram. Int., 31, 663–665 (2005).

Y. P. Fu, “Preparation of Y3Al5O12 : Ce powders by microwave-induced combustion process and their luminescent properties,” J. All. Compd., 414, 181–185 (2006).

J. Li, Y. B. Pan, F. G. Qiu, et al., “Nanostructured Nd : YAG powders via gel combustion: The influence of citrate-to-nitrate ratio,” Ceram. Int., 34, 141–149 (2008).

J. Li, Y. B. Pan, F. G. Qiu, et al., “Synthesis of nanosized Nd : YAG powders via gel combustion,” Ceram. Int., 33, 1047–1052 (2007).

H. Z. Wang, L. Gao, and K. Niihara, “Synthesis of nanoscaled yttrium aluminum garnet powder by the coprecipitation method,” Mater. Sci. Eng. A, 288, 1–4 (2000).

P. Palmero, C. Esnouf, L. Montanaro, and G. Fantozzi, “Influence of the co-precipitation temperature on phase evolution in yttrium-aluminum oxide materials,” J. Eur. Ceram. Soc., 25, 1565–1573 (2005).

F. L. Yuan and H. Ryu, “Ce-doped YAG phosphor powders prepared by co-precipitation and heterogeneous precipitation,” Mater. Sci. Eng. B, 107, 14–18 (2004).

G. G. Xu, X. D. Zhang, W. He, et al., “Preparation of highly dispersed YAG nano-sized powder by coprecipitation method,” Mater. Lett., 60, 962–965 (2006).

J. G. Li, T. Ikegami, J. H. Lee, et al., “Co-precipitation synthesis and sintering of yttrium aluminum garnet (YAG) powders: the effect of precipitant,” J. Eur. Ceram. Soc., 20, 2395–2405 (2000).

L. Wen, X. D. Sun, Z. M. Xiu, et al., “Synthesis of nanocrystalline yttria powder and fabrication of transparent YAG ceramics,” J. Eur. Ceram. Soc., 24, 2681–2688 (2004).

G. G. Xu, X. D. Zhang, W. He, et al., “The study of surfactant application on synthesis of YAG nano-sized powders,” Powder Technol., 163, 202–205 (2006).

Author information

Authors and Affiliations

Corresponding author

Additional information

Published in Poroshkovaya Metallurgiya, Vol. 48, Vol. 48, No. 7–8 (468), pp. 59–65, 2009.

Rights and permissions

About this article

Cite this article

Li, X., Wang, W. & Hu, ZG. Preparation of uniformly dispersed YAG ultrafine powders by coprecipitation method with SDS treatment. Powder Metall Met Ceram 48, 413–418 (2009). https://doi.org/10.1007/s11106-009-9149-0

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11106-009-9149-0