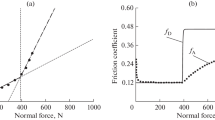

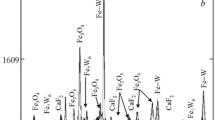

The paper examines the effect of nickel and phosphorus on the performance characteristics of antifriction graphite-bronze powder materials under high pressures (to 20 MPa), at substantial sliding velocities (1–2 m/sec), and with a liquid lubricant supplied from an oil-impregnated felt pad. It is established that Cu-Ni-P-C graphite bronze of the optimal composition has a friction coefficient of 0.028–0.045 and can perform till 150°C in the above conditions. The material is microheterogeneous: the bearing structural component is α solid solution of nickel in copper with the hardening phase being evenly distributed along its boundaries (Cu3P mesh with inclusions of phosphide eutectic (Cu-Ni) + Cu3P); the antifriction structural component represents graphite inclusions evenly distributed in the material matrix.

Similar content being viewed by others

References

I. M. Fedorchenko and L. I. Putina, Antifriction Sintered Composite Materials [in Russian], Naukova Dumka, Kiev (1980), p. 440.

V. N. Klimenko and I. M. Fedorchenko, GOST 26719-85: Antifriction Copper-Based Powder Materials. Grades [in Russian], Introduced December 19, 1985.

Powder Metallurgy Abroad: Signal Information on Company Documentation [in Russian], Issue 1–2, Kiev (1977).

V. V. Saklinskii, Properties of Metal Ceramics and Their Application in Mechanical Engineering [in Russian], Moscow (1964), p. 36.

Properties of Metal Powders, Refractory Compounds, and Sintered Materials: Handbook [in Russian], Naukova Dumka, Kiev (1978), p. 182.

V. I. Pavlenko and D. S. Yas', Modern Copper and Graphite-Bronze Materials and Their Application in Light Industry (Express Information, Textile Industry) [in Russian], TsNII Inf. Tekh. Ékon. Issled. Legk. Prom.

S. A. Chernavskii, Sliding Bearings [in Russian], Mashgiz, Moscow (1963), p. 243.

A. G. Kostornov, Yu. M. Simeonova, O. I. Fushchich, et al., “Determining impact of the tribological synthesis of new structures in the friction zone on operating properties of antifriction materials,” in: Friction and Wear Problems (Collected Scientific Papers) [in Ukrainian], Issue 46, Aviat. Univ. (2006), pp. 109–121.

A. G. Kostornov, O. I. Fushchich, T. M. Chevychelova, and O. D. Kostenko, “Effect of alloying components on the tribotechnical properties of iron-based powder material,” in: Friction and Wear Problems (Collected Scientific Papers) [in Ukrainian], Issue 47, Aviat. Univ. (2007), pp. 121–131.

Yu. V. Naidich, V. M. Perevertailo, and G. M. Nevodnik, “Wetting of graphite by nickel as affected by the liquid-phase dissolution process of carbon,” Powder Metall. Met. Ceram., 10, No. 1, 45–47 (1971).

I. V. Kragel'skii and V. V. Alisin (eds.), Friction, Wear, and Lubrication [in Russian], Vol. 1, Mashinostroenie, Moscow (1978).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Poroshkovaya Metallurgiya, Vol. 47, No. 9–10 (463), pp. 68–76, 2008.

Rights and permissions

About this article

Cite this article

Fushchich, O.I., Varchenko, V.T. Effect of alloy components on the performance characteristics of antifriction graphite-bronze powder material. Powder Metall Met Ceram 47, 557–562 (2008). https://doi.org/10.1007/s11106-008-9058-7

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11106-008-9058-7