Abstract

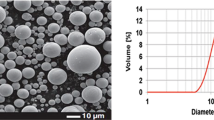

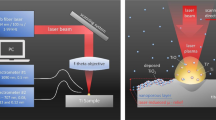

The paper describes the selective laser fusion of spherical titanium powders with a titanium base in which solid-state (YAG: Nd3+) laser is used as a radiation source. Metallographic data on single-layer coatings of spherical titanium powders show that the liquid-phase formation of metal contacts resulting from the surface fusion of powder particles underlies the mechanism of selective laser sintering of porous materials.

Similar content being viewed by others

References

M. Shakery, S. T. S. Al-Hassani, and T. J. Davies, “Discharge powder compaction,” Powder Met., 11, No. 3, 120–124 (1979).

A. Ph. Ilyschenko, V. V. Savich, K. E. Belyavin, and D. V. Minko, “Technology of powder metallurgy and spraying protective coatings for implants production,” in: Proc. 3rd Symposium Orthopedic and Prosthetic Engineering (IOP 2001), Bialystok (2001), pp. 57–65.

E. A. Doroshkevich, V. K. Sheleg, A. A. Radchenko, et al., Forty Years of Powder Metallurgy in Republic of Belarus' [in Russian], Minsk (2000), p. 347.

N. M. Aleksandrov and P. Z. Arzhantsev, Jaw Fractures [in Russian], Meditsina, Leningrad (1986), p. 286.

J. Hanninen, “Direct metal laser sintering,” Adv. Mat. Proc., 33–35 (2002).

A. Godavarty, A. Agarwal, N. B. Dahotre, “Neural networks in studies on oxidation behavior of laser surface engineered composite boride coatings,” Appl. Sur. Sci., 161, 131–138 (2000).

F. T. Cheng, C. T. Kwork, and H. C. Man, “Laser surfacing of S31603 stainless with engineering ceramics for cavitation erosion resistance,” Surf. Coat. Techn., 139, 14–24 (2001).

N. N. Rykalin and A. A. Uglov, “Plasma-assisted laser treatment of metals at high gas pressures,” Kvant. Élektron, 8, No. 6, 1193–1201 (1981).

S. A. Astapchik, V. S. Golubev, A. G. Maklakov, and V. V. Vaganov, “Producing cutting tools by laser welding,” Svarshchik v Belarusi, No. 1, 8–11 (2003).

O. G. Devoino, Formation of Wear-Resistant Surfaces by Laser Alloying [in Russian], Minsk (2001), p. 180.

N. K. Tolochko, S. E. Mozzharov, N. V. Sobolenko, et al., “Problems and prospects of selective layer-by-layer laser sintering of powders,” Powder Metall. Met. Ceram., 34, No. 3–4, 142–145 (1996).

N. K. Tolochko, I. A. Yadroitsev, S. E. Mozzarov, and V. B. Michailov, “Selective laser sintering,” in: Proc. PM 98 World Congress (Granada, Spain, 1998), Granada (1998), Vol. 5, pp. 407–412.

V. V. Bar'yash, “Basic principles of using permeable compression plates for the ostheosynthesis of traumatic lower jaw fractures,” in: Pressing Problems of Biology and Medicine [in Russian], Minsk (1996), pp. 362–363.

Yu. G. Shaposhnikov, Endoprosthetics Replacement in Traumatology and Orthopedics [in Russian], Moscow (1993), p. 383.

O. P. Chudakov and V. V. Bar'yash, “Indications and contra-indications to the ostheosynthesis with porous titanium compression plates in traumatic lower jaw fractures,” in: Pressing Problems of Biology and Medicine, Minsk (1996), pp. 487–488.

S. S. Kiparisov and G. A. Liberson, Powder Metallurgy [in Russian], Metallurgiya, Moscow (1971), p. 528.

K. E. Belyavin, D. V. Min'ko, R. P. Bykov, and O. O. Kuznechik, “Examining the effect of pulse-periodic laser radiation on the stability of liquid-metal contacts between powder particles in selective laser sintering,” Poroshk. Metall., Minsk, Issue 29, 29–32 (2006).

K. E. Belyavin, D. V. Min'ko, R. P. Bykov, and O. O. Kuznechik, “Modeling the deposition process in pulse-periodic laser impact on titanium powder”, Welding and Related Processes, Issue 8, Minsk (2006).

S. A. Astapchik, “Phase and structural transformations in steels and alloys in laser heating,” Izv. AN BSSR, Ser. Fiz.-Tekh. Nauk, No. 4, 3–35 (1982).

K. E. Belyavin, V. V. Mazyuk, D. V. Min'ko, and V. K. Sheleg, Theory and Practice of Electric Pulse Sintering of Powder Materials [in Russian], Remiko Ltd., Minsk (1997), p. 180.

D. V. Min'ko, O. O. Kuznechik, Yu. Chivel', and V. K. Pavlenko, Powder Stereolithography Laser Facility [in Russian], Patent No. 2299787, Russian Federation, Published October 21, 2004.

Author information

Authors and Affiliations

Corresponding author

Additional information

__________

Translated from Poroshkovaya Metallurgiya, Vol. 47, No. 7–8 (462), pp. 155–160, 2008.

Rights and permissions

About this article

Cite this article

Belyavin, K.E., Min’ko, D.V., Kuznechik, O.O. et al. Solid-state laser fusion of spherical titanium powders. Powder Metall Met Ceram 47, 500–504 (2008). https://doi.org/10.1007/s11106-008-9049-8

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11106-008-9049-8