Abstract

The paper examines how temperature and strain rate influence the deformation of a porous powder billet made of an antifriction material. Copper and nickel-based alloy powders produced from industrial waste are used as the initial material. The ultimate strain in compression is established and used to calculate the mold sizes in tool development. Ambiguous temperature dependence of the mechanical and antifriction properties is obtained. Temperature and strain rate that ensure satisfactory mechanical and antifriction properties are found. Processes for producing parts from the antifriction material are proposed.

Similar content being viewed by others

References

I. D. Radomysel’kii, D. S. Yas’ and V. I. Pavlenko, Production and Use of Powder Parts in Light Industry [in Russian], Tekhnika, Kiev (1982), p. 175.

D. Dankly, “Towards higher performance PM,” Powder Metallurgy, 46, No. 2, 108–109 (2003).

A. V. Dovydenkova and I. D. Radomyselskii, “Production and properties of constructional parts from copper and copper alloy powders,” Powder Metall. Met. Ceram., 21, No. 3, 196–203 (1982).

L. A. Ryabicheva, Yu. N. Nikitin, A. T. Tsyrkin, et al., “Production of copper powder from current conductor waste,” Metalloobrabotka, No. 3, 40–42 (2004).

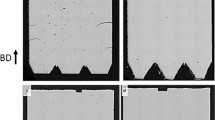

L. A. Ryabicheva, M. B. Shtern, and A. T. Tsyrkin, “Deformation and fracture of porous copper at high temperatures,” in: Proc. 1st Int. Conf. Deformation and Fracture of Materials (November 13–16, 2006), Moscow (2006), pp. 20–24.

Yu. G. Dorofeev, Dynamic Hot Pressing of Porous Materials [in Russian], Nauka, Moscow (1968), p. 122.

D. N. Garkunov, Triboengineering [in Russian], Mashinostroenie, Moscow (1989), p. 328.

Author information

Authors and Affiliations

Corresponding author

Additional information

__________

Translated from Poroshkovaya Metallurgiya, Vol. 47, No. 5–6 (461), pp. 44–51, 2008.

Rights and permissions

About this article

Cite this article

Ryabicheva, L.A., Nikitin, Y.N. Production and properties of copper-based powder antifriction material. Powder Metall Met Ceram 47, 299–303 (2008). https://doi.org/10.1007/s11106-008-9020-8

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11106-008-9020-8