Abstract

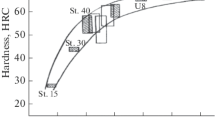

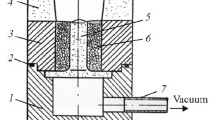

The paper examines the production of a composite material that is double hardened by adding titanium carbides and borides to the steel and by quenching the metal matrix and letting it to age. Samples containing 30 wt.% TiC or TiB2 are produced by liquid phase sintering, hot pressing, and hot forging. The effect of thermal treatment on the mechanical properties and structural state of the material is investigated. The material quenched and aged is established to be twice as durable and hard as the sintered one. Hence, it can be mechanically treated after sintering and then thermally treated. The highest possible strength of the material produced is 1400 to 1500 MPa and hardness 60 to 65 HRC. Strengthening worn reinforcing-wire knives with plates of the composite material prolonged their life by 50 to 100% compared with the standard knife.

Similar content being viewed by others

References

I. D. Bykov, G. L. Dubrov, Yu. F. Bokii, et al., “Experience in the manufacture of tools in carbide-containing steel,” Powder Metall. Met. Ceram., 23, No. 5, 365–369 (1984).

Ya. P. Kyubarsepp, “Effect of carbon concentration in binder on the mechanical properties of heat-treatable titanium carbide-steel alloys,” Powder Metall. Met. Ceram., 24, No. 3, 214–216 (1985).

M. D. Perkas and V. M. Kardonskii, High-Strength Maraging Steels [in Russian], Metallurgiya, Moscow (1970), p. 224.

Yu. A. Stolyarchuk, É. F. Benua, V. I. Trefilov, et al., “Maraging steel,” USSR Inventor’s Certificate No. 1185885, Otkryt. Izobr., No. 38 (1985).

V. G. Gorbach and Yu. I. Samsonov, “Method of thermal treatment of aging austenite-martensite alloys,” USSR Inventor’s Certificate No. 340709, Otkryt. Izobr., No. 18 (1972), p. 92.

V. G. Gorbach and Yu. I. Samsonov, “Mechanical properties of two-phase alpha-and gamma-aging iron alloys,” Fiz. Met. Metalloved., 34, No. 4, 822–829 (1972).

Yu. I. Samsonov, O. M. Shevchenko, and V. P. Maiboroda, “Effect of stabilizing treatment on the kinetics of martensitic transformation and strength of metastable Fe-Ni-based aging alloys,” Metallofiz. Noveish. Tekhnol., 27, No. 11, 1419–1427 (2005).

Author information

Authors and Affiliations

Additional information

__________

Translated from Poroshkovaya Metallurgiya, Vol. 46, No. 7–8 (456), pp. 28–34, 2007.

Rights and permissions

About this article

Cite this article

Drachinskii, A.S., Maslyuk, V.A., Samsonov, Y.I. et al. Sintered metals and alloys. Powder Metall Met Ceram 46, 332–337 (2007). https://doi.org/10.1007/s11106-007-0053-1

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11106-007-0053-1