Abstract

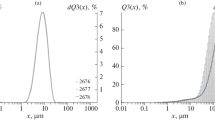

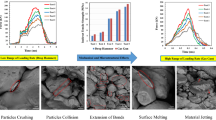

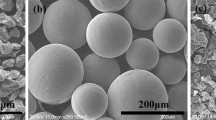

Processes of warm compression of mixtures of iron powder with organic binder (animal fat, zinc stearate) are investigated. Comparative experiments on the compressibility of SC-100.26 and PZhRV-200.28 iron with different binders are conducted. An increment in the density in warm compression of iron powder is achieved only where the iron powder is of high ductility, high purity, and the lubricants present in the mixture are of sufficient viscosity at the temperature and pressure of warm compression.

Similar content being viewed by others

References

G. V. Samsonov and M. S. Koval’chenko, Hot Compression [in Russian], State Technical Literature Press, UkrRSS, Kiev (1962), 210 pp.

A. K. Butylenko and V. N. Sokolovskii, “A study of the compression of metal powders upon heating under high pressure to 80 kbar,” Poroshk. Metall., No. 11, 28–33 (1978).

S. K. Sah and S. M. Kaufman, “Liquid phase compacting,” Mod. Dev. Powder Met., 12, 613–629 (1981).

Hoganas Handbook for Warm Compaction, Hoganas (1998), 112 pp.

G. F. Bocchini, “Warm compaction of metal powder,” Powder Metallurgy, 42, No. 2, 171–180 (1999).

PM2 Tec 2003. PM industry turning the corner, Powder Metallurgy, 46, No. 2, 105–109 (2003).

V. N. Gorokhov, E. V. Zvonarev, and E. S. Sevast’yazov, “Warm deformation of unsintered billets of low-alloy powder steels,” in: Materials and Coatings under Extremal Conditions: Investigation, Application, and Economically Pure Technologies for Production and Recycling of Finished Articles, Proc. International Conference, Katsiveli (Crimea, Ukraine) (2000), p. 41.

J. Bord and A. Jameson, “Influence of carbon, nitrogen, and manganese on high-temperature tensile strength of iron,” in: Structure and Mechanical Properties of Metals [in Russian], Metallurgiya, Moscow (1967), pp. 161–171.

W. D. Jones, Foundations of Powder Metallurgy. Compression and Sintering [Russian translation], Mir, Moscow (1965), 403 pp.

I. T. Goronovskii, Yu. P. Nazarenko, and E. F. Nekryag, Short Manual in Chemistry [in Russian], Nauk. Dumka, Kiev (1974), 992 pp.

Author information

Authors and Affiliations

Additional information

__________

Translated from Poroshkovaya Metallurgiya, Nos. 11–12(452), pp. 114–119, November–December, 2006.

Rights and permissions

About this article

Cite this article

Maslyuk, V.A., Sosnovskii, L.A., Minitskii, A.V. et al. Certain features of warm isothermal compression of iron powder. Powder Metall Met Ceram 45, 605–609 (2006). https://doi.org/10.1007/s11106-006-0126-6

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11106-006-0126-6