Abstract

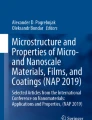

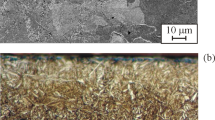

Studies have been performed on the phase compositions, surface relief, adhesion, and mechanical properties of monolayer and multilayer coatings based on TiN and TiN-Ti-TiNO. Resistance tests to microabrasive wear have been made on these. Such wear on multilayer coatings is less by a factor 1.9 than on monolayer ones. Multilayer coatings of TiN-Ti-TiNO have high adhesion to silicon; a difference from monolayer coatings is that they are not subject to peeling with the maximum normal loading by a diamond indenter during nanoscratching. The coefficient of friction is 0.17 in diamond indenter scratching of monolayer and multilayer coatings.

Similar content being viewed by others

References

M. R. Hilton, G. J. Vandentop, M. Salmeron, and G. A. Somorjai, “TiN coatings on steel produced by plasma-assisted chemical vapor deposition,” Thin Solid Films, 154, 377 (1987).

Wen-Jun Chou, Ge-Ping Yu, and Jia-Hong Huang, “Mechanical properties of TiN thin film coatings on 304 stainless steel substrates,” Surface and Coatings Technology, 149, 7–13 (2002).

E. Badish, M. Stoiber, G. A. Fontalvo, and C. Mitterer, “Low-friction PACVD TiN coatings: Influence of Cl-content and testing conditions on the tribological properties,” Surface and Coatings Technology, 174–175, 450–454 (2003).

Youl-Moon Sung and Hee-Je Kim, “Optimum substrate bias condition for TiN thin film deposition using an ECR sputter system,” Surface and Coatings Technology, 171, 75–82 (2002).

P. Huber, D. Manova, S. Mandl, and B. Rauschenbach, “Formation of TiN, TiC and TiCN by metal plasma immersion ion implantation and deposition,” Surface and Coatings Technology, 174–175, 1243–1247 (2003).

F. Vaz, P. Machado, L. Rebouta, et al., “Mechanical characterization of reactively magnetron-sputtered TiN films,” Surface and Coatings Technology, 174–175, 375–382 (2003).

D. N. Allsopp and I. M. Hutchings, “Micro-scale abrasion and scratch response of PVD coatings at elevated temperatures,” Wear PVD, 251, 1308–1314 (2001).

V. Imbeni, C. Martini, E. Lanzoni, et al., “Tribological behaviour of multi-layered nitride coatings,” Wear PVD, 251, 997–1002 (2001).

G. S. Kim, S. Y. Lee, J. H. Hahn, et al., “Effect of the thickness of Ti buffer layer on the mechanical properties of TiN coatings,” Surface and Coatings Technology, 171, 83–90 (2002).

Yu. V. Panfilov, “Multilayer hard coatings for machinery needs,” Nanostructured Thin Films and Nanodispersion Strengthened Coatings, A. A. Voevodin, et al. (eds.), Kluwer Academic Publishers, Dordrecht, Boston, London (2004), pp. 69–76.

N. J. M. Carvalho, E. Zoestbergen, B. J. Kooi, and J. Th. M. De Hosson, “Stress analysis and microstructure of PVD mono-layer TiN and multi-layered TiN/(Ti, Al)N coatings,” Thin Solid Films, 429, 179–189 (2003).

P. Jedrzejowski, J. E. Klemberg-Sapiehaand, and L. Martinu, “Optical properties and color of hard quaternary nanocomposite TiCxNy/SiCN coatings prepared by plasma enhanced chemical vapor deposition,” Surface and Coatings Technology, 188–189, 371–375 (2004).

S. Veprek, “Recent progress in superhard nano-composites: Preparation, properties and industrial applications,” Nanostructured Thin Films and Nanodispersion Strengthened Coatings, A. A. Voevodin, et al. (eds.), Kluwer Academic Publishers, Dordrecht, Boston, London (2004), pp. 23–34.

L. A. Ivashchenko and G. V. Rusakov, “Plasmochemical deposition applied to make oxycarbonitride coatings on hard alloys,” Poroshk. Metall., No. 2, 18–23 (1992).

L. A. Ivashchenko, O. K. Porada, V. I. Ivashchenko, et al., “Nano-structured TiN based PECVD coatings,” Proc. of the 3rd Intern. Conf. “Material and Coatings for Extreme Performance: Investigations, Applications, Ecologically Safe Technologies for their Production, and Utilization” (September 13–17, 2004, Katsiveli, Crimea, Ukraine), V. V. Skorokhod (ed.), Kiev (2004), pp. 163–164.

L. A. Ivashchenko, G. V. Rusakov, O. K. Porada, and V. I. Ivashchenko, “Wear-and corrosion-resistant coatings of silicon carbide and titanium carbonitride,” Conf. Proc. “EUROMAT 2001” (July 10–14, 2001, Rimini, Italy), Rimini (2001).

L. A. Ivashchenko, G. V. Rusakov, V. I. Ivashchenko, and O. K. Porada, “Peculiarity of preparing a-SiC: H films from methyltrichlorosilane,” Appl. Surface Sci., 184, 128–134 (2001).

Author information

Authors and Affiliations

Additional information

__________

Translated from Poroshkovaya Metallurgiya, Nos. 11–12(452), pp. 48–54, November–December, 2006.

Rights and permissions

About this article

Cite this article

Ivashchenko, L.A., Porada, O.K., Ivashchenko, V.I. et al. Characteristics of monolayer and multilayer titanium nitride plasmochemical coatings. Powder Metall Met Ceram 45, 547–552 (2006). https://doi.org/10.1007/s11106-006-0118-6

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11106-006-0118-6