Abstract

We have studied phase formation in detonation coatings sprayed from Ti - 50 at.% Al powders. The powders of the alloy were obtained by various methods: crushing an ingot and mechanical alloying of Ti and Al. Using polyphase nanostructural materials activated by mechanical alloying makes the process of phase formation in the gas-thermal sprayed coatings based on them more general-purpose and controlled due to the more active and more subtle reaction of the material with the gaseous atmosphere. We have shown that from mechanically alloyed Ti - 50 at.% Al powder, using the detonation-gas spraying method we can consolidate a coating based on Al2TiO5 by oxidizing action of the working gas on the powder and also a coating based on titanium aluminides with TiN inclusions by nitriding action. The phase composition of the cast microstructural γ-TiAl powder is inherited by the coating.

Similar content being viewed by others

REFERENCES

M. P. Brady, W. J. Brindley, J. L. Smialec, and I. E. Lossi, “Oxidation and protection of γ titanium aluminides,” J. Oxidation Met., 46–50, November (1996).

V. E. Oliker and V. S. Kresanov, “Structure and properties of detonation coatings based on γ-TiAl,” Poroshk. Metall., Nos. 11–12, 82–88 (2000).

V. E. Oliker and V. S. Kresanov, “Scandium-containing gamma titanium aluminide alloys and coatings for aerospace structural parts,” in: Advanced Materials and Processes for Gas Turbines, Minerals, Metals and Materials Society, Warrendale (2003), pp. 293–300.

G. H. Meir, D. Appalonia, R. A. Perkins, and K. T. Chiang, “Oxidation of Ti-base alloys,” in: Oxidation of High Temperature Intermetallic, T. Grobstein and J. Doychak (eds.), Minerals, Metals, and Materials Society, Warrendale (1988), pp. 185–189.

S. Taniguchi, T. Shibata, and S. Itoh, “Oxidation behavior of TiAl at high temperatures in purified oxygen,” Mater. Trans., 32, No.2, 151–157 (1991).

K. L. Luthra, “Stability of protective oxide films on Ti-base alloys,” Mater. Trans., 36, Nos. 5–6, 475–482 (1991).

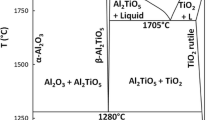

A. Raxmel and P. J. Spencer, “Thermodynamic aspects of TiAl and TiSi2 oxidation: the Al-Ti-O and Si-Ti-O phase diagrams,” Mater. Trans., No. 1–2, 53–59 (1991).

S. Becker, A. Rahmel, M. Schorr, and M. Schutze, “Mechanism of isothermal oxidation of intermetallic TiAl and of TiAl alloys,” Oxidation Met., 38, No.5–6, 427–433 (1992).

Y. F. Cheng, F. Dettenwanger, J. Mayer, et al., “Identification of a new phase formed during the oxidation of titanium aluminum,” Scripta Mat., 34, No.5, 707–711 (1996).

M. Eckert and K. Hilpert, “Determination of thermodynamic activities in the alloys of the Ti-Al system and prediction of the oxidation behavior of the alloys,” Mat. Corrosion, 48, Nos. 10–12, 10–12 (1997).

F. Dettenwanger, E. Schuman, M. Ruhle, et al., “Microstructural study of oxidized TiAl,” J. Oxidation Met., 50, No.3–4, 269–273 (1998).

V. O. Lavrenko, S. O. Firstov, A. D. Panasyuk, et al., “Corrosion of intermetallics in the titanium-aluminum system. I. High-temperature oxidation of the intermetallics γ-TiAl, TiAl3, and α2-Ti3Al,” Poroshk. Metall., Nos. 3–4, 89–95 (2003).

R. F. Voitovich and E. I. Golovko, High-Temperature Oxidation of Titanium and Titanium Alloys [in Russian], Nauk. Dumka, Kiev (1984).

Phase Diagrams of Refractory Oxide Systems: Handbook, in the series: Binary Systems [in Russian], Nauka, Leningrad (1985), No. 5, Pt. 1.

F. H. Froes, C. Surynarayana, K. Russell, and C.-G. Li, “Synthesis of intermetallics by mechanical alloying,” J. Mat. Sci., A192/193, 612–623 (1995).

O. M. Ivasishin, A. N. Demidik, and D. G. Savvakin, “Use of titanium hydride for synthesis of titanium aluminides from powder materials,” Poroshk. Metall., Nos. 9–10, 63–69 (1999).

V. E. Oliker, V. S. Kresanov, V. L. Sirovatka, et al., “Mechanochemical synthesis, structure, and properties of alloys based on the Ti-Al system,” Poroshk. Metall., Nos. 1–2, 43–56 (2003).

V. V. Skorokhod, “Some problems in synthesis technology, study of the structure and properties of nanocrystalline materials,” in: Nanocrystalline Materials: Collected Scientific Papers [in Russian], Institute for Problems of Materials Science, National Academy of Sciences of Ukraine, Kiev (1998), pp. 4–13.

V. E. Oliker, V. I. Trefilov, V. S. Kresanov, et al., “Effect of scandium and chromium on the structure and scaling resistance of alloys based on γ-TiAl,” Poroshk. Metall., Nos. 9–10, 82–88 (2000).

C. Z. Carroll-Porczynski, Advanced Materials [Russian translation from English], Mir, Moscow (1966).

D. E. Grady, “Phase transformation under shock loading,” in: Alloy Phase Diagrams, L. H. Bennett, T. B. Massalski, and B. C. Giessen (eds.) [Russian translation from English], Mir, Moscow (1986).

A. I. Zverev, S. Yu. Sharivker, and E. A. Astakov, Detonation Spray Coating [in Russian], Sudostroenie, Leningrad (1979).

Author information

Authors and Affiliations

Additional information

__________

Translated from Poroshkovaya Metallurgiya, Nos. 9–10(445), pp. 74–84, September–October, 2005.

Rights and permissions

About this article

Cite this article

Oliker, V.E., Sirovatka, V.L., Timofeeva, I.I. et al. Effect of Properties of Titanium Aluminide Powders and Detonation Spraying Conditions on Phase and Structure Formation in Coatings. Powder Metall Met Ceram 44, 472–480 (2005). https://doi.org/10.1007/s11106-006-0012-2

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11106-006-0012-2