Abstract

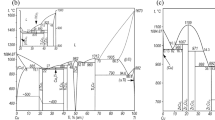

Physicochemical analysis methods have been applied to the phase equilibria in the Ti - TiNi - Sc0.53Ni0.47 - Sc subsystem of the Ti - Ni - Sc ternary system. No ternary compounds are found in the subsystem. Isomorphous phases based on Ti2Ni and Sc0.72Ni0.28 form continuous series of solid solutions (η) at subsolidus temperatures, as do the equiatomic compounds TiNi and Sc0.53Ni0.47. The crystallization of the η phase in the ternary system is incongruent, as in the binary systems Ti - Ni and Sc - Ni. The solidus surface for the Ti - TiNi - Sc0.53Ni0.47 - Sc subsystem has a nonvariant four-phase reaction of transition type at 830 °C. The compositions of the alloys that take part in it extend to the Sc - Ni side.

Similar content being viewed by others

REFERENCES

O. L. Semenova, N. Yu. Rusets'ka, T. Ya. Velikanova, and V. M. Vereshchak, “Reactions in the crystallization of alloys in the Ti-Ni-Sc system in the TiNi-Ni-ScNi region,” Poroshk. Metall., Nos. 7–8, 134–140 (1996).

E. L. Semenova, N. Yu. Rusetskaya, and V. M. Petyukh, “Projection of the solidus surface for the Sc-Ti-Ni system in the region of TiNi-Ni-ScNi alloys,” Poroshk. Metall., Nos. 11–12, 37–44 (1996).

T. B. Massalski (ed.), Binary Alloys Phase Diagrams, Vol. 1, 2, ASM, Metals Park, OH (1986).

E. M. Savitskii and G. S. Brukhanova, “The phase diagram for alloys in the titanium-scandium system,” Neorgan. Khimiya, 6, 1253–1255 (1961).

B. J. Beaudry and A. H. Daane, “Sc-Ti system and allotropy of Sc,” Trans. Metal. Soc. AIME, 224, 770–775 (1962).

V. M. Danilenko, N. Yu. Rusetskaya, E. L. Semenova, and A. B. Yagodkin, “Thermodynamic modeling of the Sc-Ti system,” Poroshk. Metall., Nos. 7–8, 63–68 (1999).

E. L. Semenova and N. Yu. Rusetskaya, “The Sc-Ni system,” J. Alloys Comp., 262–263, 258–262 (1997).

Inorganic-Material Encyclopedia [in Russian], Nauk. Dumka, Kiev (1977).

K. A. Gschneider Jr., “Physical properties of the rare earth metals,” Bull. Alloy Phase Diagr., 11, No.3, 216–223 (1990).

P. Villars and L. D. Calvert, Pearson Handbook of Crystallographic Data for Intermetallic Phases, Vols. 1–4, ASM, Metal Park, OH (1991).

E. L. Semenova and Yu. V. Kudryavtsev, “Structural phase transformation and shape memory effect in ZrRh and ZrIr,” J. Alloys Comp., 203, 165–168 (1994).

V. N. Eremenko, E. L. Semenova, and L. A. Tret'yachenko, “The liquidus surface and crystallization scheme for alloys in the Ti-Ni-Zr system containing up to 50 at.% Ni,” Poroshk. Metall., No. 8, 49–54 (1991).

O. L. Semenova and L. O. Tret'yachenko, “The solidus surface in the Ti-Ni-Hf system in the region Ti-TiNi-HfNi-Hf,” Poroshk. Metall., Nos. 7–8, 119–131 (2001).

M. Yu. Teslyuk, Metal Compounds with Laves Phase Structures [in Russian], Nauka, Moscow (1969).

Author information

Authors and Affiliations

Additional information

__________

Translated from Poroshkovaya Metallurgiya, Nos. 9–10(445), pp. 54–63, September–October, 2005.

Rights and permissions

About this article

Cite this article

Velikanova, T.Y., Krendelsberger, N.Y. & Semenova, O.L. Phase Equilibria in the Melting - Crystallization Region for Alloys in the Ti - TiNi - Sc0.53Ni0.47 - Sc Subsystem. Powder Metall Met Ceram 44, 455–462 (2005). https://doi.org/10.1007/s11106-006-0009-x

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11106-006-0009-x