Abstract

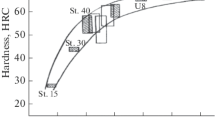

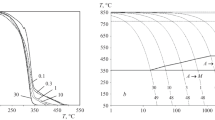

The effect of thermomechanical strengthening of powder materials of several compositions (steel Kh18N15 without additives, with added carbon, and also with additions of Cr2C3, MoS2 and carbon) during hot forming is established by experiment. This effect is detected by comparing the physicomechanical properties of specimens, prepared by high-temperature thermomechanical treatment, with specimens of a similar composition subjected to complete annealing and hardening after separate heating. The different nature in the dependence of strength properties for steel Kh18N15 without additions and a composite based upon it on shear strain intensity during forming is established. Thermomechanical strengthening of hot-formed single-phase stainless steel is traditional in nature: with an increase in the intensity of shear strain steel strength properties increase, but conversely for a composite they decrease and this is explained by the specific nature of its structure formation during forming.

Similar content being viewed by others

REFERENCES

S. G. Napara-Volgina, L. N. Kostyrko, and I. D. Radomysel'skii, “Heat and thermomechanical treatment of powder steels,” Poroshk. Metall., No. 10, 49–67 (1983).

V. N. Antsiferov and V. B. Akimenko, Sintered Alloy Steels [in Russian], Metallurgiya, Moscow (1983).

B. A. Borok, Zh. I. Dzneladze, and V. N. Plechev, Inventor's Certificate 454092 USSR, “Thermomechanical method for treating dispersion-strengthened materials,” Otkrytiya. Izobreteniya, No. 47 (1974).

M. L. Bershtein, V. S. Rakovskii, and F. L. Lokshin, Inventor's Certificate 385673 USSR, “Thermomechanical treatment method for articles,” Otkrytiya. Izobreteniya, No. 26 (1973).

M. L. Bershtein and S. G. Mamyan, “High-temperature strengthening of sintered structural steels,” in: Increase in the Structural Strength of Steels and Alloys [in Russian], Metallurgiya, Moscow (1970).

S. G. Mamyan, Effect of TMT on the Structure and Properties of Powder Steels, PhD Thesis [in Russian], Moscow (1971).

I. D. Radomysel'skii, A. I. Dzhubenko, A. P. Lyapunov, et al., “High-strength carbon steels with an inherited-crystalline structure. III. Effect of structure on the mechanical properties of powder carbon steels,” Poroshk. Metall., No. 1, 91–93 (1987).

I. D. Radomysel'skii, A. I. Dzhubenko, A. P. Lyapunov, et al., “High-strength carbon steels with an inherited-crystalline structure. IV. Some features of structure formation during heat treatment of powder carbon steels,” Poroshk. Metall., No. 4, 80–88 (1987).

V. A. Maslyuk, S. G. Napara-Volgina, and V. K. Kud', “Composites based on stainless steels,” Poroshk. Metall., Nos. 11–12, 33–38 (2000).

V. M. Segal, V. I. Reznikov, and V. F. Malyshev, “Change in the density of porous materials during plastic forming,” Poroshk. Metall., No. 7, 6–11 (1979).

M. V. Storozhev and A. E. Popov, Metal Forming Theory [in Russian], Mashgiz, Moscow (1957).

Yu. G. Dorofeev, Dynamic Hot Compaction in Cermets [in Russian], Metallurgiya, Moscow (1972).

Author information

Authors and Affiliations

Additional information

__________

Translated from Poroshkovaya Metallurgiya, Nos. 9–10(445), pp. 29–37, September–October, 2005.

Rights and permissions

About this article

Cite this article

Napara-Volgina, S.G., Maslyuk, V.A. Thermomechanical Strengthening of Powder Stainless Steel of the Austenitic Class and Wear-Resistant Composites Based upon It. Powder Metall Met Ceram 44, 435–440 (2005). https://doi.org/10.1007/s11106-006-0005-1

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11106-006-0005-1