Abstract

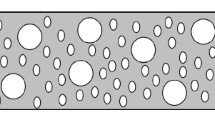

A model of sintering for materials with bimodal pore distribution is formulated as a generalization of the continuum isotropic theory of sintering. In contrast to known models that only contain one behavioral parameter, i.e. porosity, the model suggested is described by two parameters for each type of pore. The evolution equations for each type of pore as well as the effective viscosity coefficients and Laplace pressure (sintering potential) are determined by unit cell analysis.

Similar content being viewed by others

REFERENCES

V. V. Skorokhod, I. V. Uvarova, and A. V. Ragulya, Physicochemical Kinetics in Nanostructural Systems [in Russian], Akademperiodika, Kiev (2001).

D. C. Hague and M. J. Mayo, “Sinterforging of nanocrystalline zirconia. II. Simulation,” J. Amer. Ceram. Soc., 82, No.3, 149–156 (1997).

V. V. Skorokhod, S. M. Solonin, and L. I. Chernyshev, “Study of sintering mechanism for highly-porous materials with a volatile pore former,” Poroshk. Metall., No. 11, 42–47 (1974).

A. G. Kostornov, L. E. Lunin, N. E. Fedorova, and L. I. Chernyshev, “Compaction features for a mixture of metal powders with a pore former,” Poroshk. Metall., No. 6, 10–14 (1983).

V. V. Skorokhod and S. M. Solonin, Physical Metallurgy Bases of Powder Sintering [in Russian], Metallurgiya, Moscow (1984).

A. Laptev, M. Bram, H. G. Buchkremer, and D. Stoever, “Study of production for titanium parts combining very high porosity and complex shape,” Powder Metal., 47, No.1, 85–92 (2004).

A. G. Kostornov, Materials Science of Fine and Porous Materials and Alloys; in 2 Vols., Vol. 1 [in Russian], Nauk. Dumka, Kiev (2002).

Yu. M. Solonin, “Relationship of integral and local compaction during sintering of porous bodies,” Poroshk. Metall., No. 12, 25–30 (1983).

S. M. Solonin, “Contemporary ideas about the role of the geometric factor during sintering in the light of work by M. Yu. Bal'shin,” Poroshk. Metall., Nos. 11–12, 32–37 (2003).

Z. Z. Du and A. C. F. Cocks, “Constitutive models for the sintering of ceramic components,” Acta Met., 40, No.8, 1969 (1992).

V. V. Skorokhod, E. A. Olevskii, and M. B. Shtern, “Continuum theory of sintering. I. Phenomenological model,” Poroshk. Metall., No. 1, 22–29 (1993).

J. Ma and A. C. F. Cocks, “A constitutive model for the sintering of fine grained alumina,” IU-TAM Symposium on Mechanics of Granular and Porous Materials, Kluwer Academic Publishers, New York; London; Paris (1997).

O. Gillia and D. Bouvard, “Continuum modelling of sintering of powder compacts,” in: Recent Developments in Computer Modelling of Powder Metallurgy Process, IOS Press, London (2001).

E. Olevsky, “Theory of sintering from direct to continuum,” Mat. Sci. Eng., R23, 41–100 (1998).

G. W. Scherer, “Viscous sintering of bimodal pore material,” J. Amer. Ceram. Soc., 67, 369–371 (1984).

R. M. German and M. A. Bulger, “A model for densification by sintering of bimodal particle size distribution,” Int. J. Powder Met., 28, No.3, 301–311 (1992).

V. V. Skorokhod, Rheological Bases of Sintering Theory [in Russian], Nauk. Dumka, Kiev (1982).

R. Christensen, Introduction to Mechanics of Composites [Russian translation], Mir, Moscow (1982).

G. W. Scherer, “Coarsening in viscous matrix,” J. Amer. Ceram. Soc., 81, No.1, 49–54 (1998).

Author information

Authors and Affiliations

Additional information

__________

Translated from Poroshkovaya Metallurgiya, Nos. 9–10(445), pp. 21–28, September–October, 2005.

Rights and permissions

About this article

Cite this article

Kuz'mov, A.V., Shtern, M.B. Mechanics of Sintering Materials with Bimodal Pore Distribution. I. Effective Characteristics of Biporous Materials and Equations for the Evolution of Pores of Different Radii. Powder Metall Met Ceram 44, 429–434 (2005). https://doi.org/10.1007/s11106-006-0004-2

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11106-006-0004-2