Abstract

Background & Purpose

Different methods have been exploited to generate amorphous solid dispersions (ASDs) of poorly water-soluble drugs. However, the impact of processing methods on drug stability and dissolution hasn’t been studied extensively. The purpose of the current study is to investigate the impact of the two common ASD processing methods, hot-melt extrusion (HME) and spray drying, on the chemical/physical stability and supersaturation of Posaconazole (Posa) based ASDs.

Methods & Results

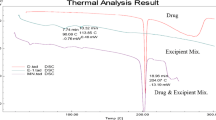

ASDs with 25% drug loading in hydroxypropylmethylcellulose acetate succinate were prepared using HME, and two types of spray dryers, a Procept Sprayer (ASD-Procept) and a Nano Sprayer (ASD-Nano). The relative physical stability of these ASDs upon exposure to heat and crystalline API seeding followed the order: ASD-Nano > ASD-Procept ≈HME. ASD-Procept and ASD-Nano showed similar chemical stability, slightly less stable than HME under 40°C/75%RH. All three ASDs demonstrated similar supersaturation induction times, and de-supersaturation kinetics with or without crystalline seeds.

Conclusions

Posa ASDs prepared via spray drying were chemically less stable compared with HME, which can be attributed to their smaller particle size and hollow structure allowing oxygen penetration. For ASD-Procept and HME, the detailed phase changes involving recrystallization of amorphous Posa and a solid-solid phase transition from Posa Form I to Form Ia during the seed-induced studies were proposed. Similar dissolution and supersaturation-precipitation kinetics of three Posa ASDs indicated that any residual nanocrystals in the bulk ASDs were not enough to induce crystallization to differentiate ASDs made by three processing methods.

Similar content being viewed by others

References

Sharma D, Soni M, Kumar S, Gupta G. Solubility enhancement—eminent role in poorly soluble drugs. Res J Pharm Technol. 2009;2(2):220–4.

Heigoldt U, Sommer F, Daniels R, Wagner K-G. Predicting in vivo absorption behavior of oral modified release dosage forms containing pH-dependent poorly soluble drugs using a novel pH-adjusted biphasic in vitro dissolution test. Eur J Pharm Biopharm. 2010;76(1):105–11.

Krishnaiah YS. Pharmaceutical technologies for enhancing oral bioavailability of poorly soluble drugs. J Bioequiv Availab. 2010;2(2):28–36.

Chaudhary A, Nagaich U, Gulati N, Sharma V, Khosa R, Partapur M. Enhancement of solubilization and bioavailability of poorly soluble drugs by physical and chemical modifications: a recent review. J Adv Pharm Educ Res. 2012;2(1):32–67.

Loftsson T, Brewster ME. Pharmaceutical applications of cyclodextrins: basic science and product development. J Pharm Pharmacol. 2010;62(11):1607–21.

Tang J-l, Sun J, He Z-G. Self-emulsifying drug delivery systems: strategy for improving oral delivery of poorly soluble drugs. Curr Drug Ther. 2007;2(1):85–93.

Kawakami K, Yoshikawa T, Hayashi T, Nishihara Y, Masuda K. Microemulsion formulation for enhanced absorption of poorly soluble drugs: II. In vivo study. J Controlled Release. 2002;81(1–2):75–82.

Js P, Kadam D, Marapur S, Kamalapur M. Inclusion complex system; a novel technique to improve the solubility and bioavailability of poorly soluble drugs: A review. Int J Pharm Sci Rev Res. 2010;2:29–34.

Van den Mooter G. The use of amorphous solid dispersions: A formulation strategy to overcome poor solubility and dissolution rate. Drug Discov Today Technol. 2012;9(2):e79–85.

Vasconcelos T, Marques S, das Neves J, Sarmento B. Amorphous solid dispersions: Rational selection of a manufacturing process. Adv Drug Del Rev. 2016;100:85–101.

Shah N, Sandhu H, Choi DS, Chokshi H, Malick AW. Amorphous solid dispersions. Theory and Practice. Springer: Berlin, Germany. 2014.

Dong Z, Chatterji A, Sandhu H, Choi DS, Chokshi H, Shah N. Evaluation of solid state properties of solid dispersions prepared by hot-melt extrusion and solvent co-precipitation. Int J Pharm. 2008;355(1–2):141–9.

Verreck G, Chun I, Peeters J, Rosenblatt J, Brewster ME. Preparation and characterization of nanofibers containing amorphous drug dispersions generated by electrostatic spinning. Pharm Res. 2003;20(5):810–7.

Brough C, Williams IR. Amorphous solid dispersions and nano-crystal technologies for poorly water-soluble drug delivery. Int J Pharm. 2013;453(1):157–66.

HengsawasSurasarang S, Keen JM, Huang S, Zhang F, McGinity JW, Williams RO III. Hot melt extrusion versus spray drying: hot melt extrusion degrades albendazole. Drug Dev Ind Pharm. 2017;43(5):797–811.

Li Y, Mann AK, Zhang D, Yang Z. Processing impact on in vitro and in vivo performance of solid dispersions—a comparison between hot-melt extrusion and spray drying. Pharmaceutics. 2021;13(8):1307.

Mann AK, Schenck L, Koynov A, Rumondor AC, Jin X, Marota M, et al. Producing amorphous solid dispersions via co-precipitation and spray drying: impact to physicochemical and biopharmaceutical properties. J Pharm Sci. 2018;107(1):183–91.

de Alencar Danda LJ, de Medeiros Batista L, Melo VCS, Sobrinho JLS, Soares MFdLR. Combining amorphous solid dispersions for improved kinetic solubility of posaconazole simultaneously released from soluble PVP/VA64 and an insoluble ammonio methacrylate copolymer. Eur J Pharm Sci. 2019;133:79–85.

Fule R, Amin P. Hot melt extruded amorphous solid dispersion of posaconazole with improved bioavailability: investigating drug-polymer miscibility with advanced characterisation. BioMed Res Int. 2014;2014:146781

Frank D, Schenck L, Koynov A, Su Y, Li Y, Variankaval N. Optimizing solvent selection and processing conditions to generate high bulk-density, co-precipitated amorphous dispersions of posaconazole. Pharmaceutics. 2021;13(12):2017.

Raad II, Hachem RY, Herbrecht R, Graybill JR, Hare R, Corcoran G, et al. Posaconazole as salvage treatment for invasive fusariosis in patients with underlying hematologic malignancy and other conditions. Clin Infect Dis. 2006;42(10):1398–403.

Cornely OA, Maertens J, Winston DJ, Perfect J, Ullmann AJ, Walsh TJ, et al. Posaconazole vs. fluconazole or itraconazole prophylaxis in patients with neutropenia. New Engl J Med. 2007;356(4):348–359.

Courtney R, Radwanski E, Lim J, Laughlin M. Pharmacokinetics of posaconazole coadministered with antacid in fasting or nonfasting healthy men. Antimicrob Agents Chemother. 2004;48(3):804–8.

Ilevbare GA, Taylor LS. Liquid–liquid phase separation in highly supersaturated aqueous solutions of poorly water-soluble drugs: implications for solubility enhancing formulations. Cryst Growth Des. 2013;13(4):1497–509.

Almeida e Sousa L, Reutzel-Edens SM, Stephenson GA, Taylor LS. Assessment of the amorphous “solubility” of a group of diverse drugs using new experimental and theoretical approaches. Mol Pharm. 2015;12(2):484–495.

Van Duong T, Ni Z, Taylor LS. Phase behavior and crystallization kinetics of a poorly water-soluble weakly basic drug as a function of supersaturation and media composition. Mol Pharm. 2022;19(4):1146–59.

Ormes JD, Zhang D, Chen AM, Hou S, Krueger D, Nelson T, et al. Design of experiments utilization to map the processing capabilities of a micro-spray dryer: particle design and throughput optimization in support of drug discovery. Pharm Dev Technol. 2013;18(1):121–9.

Djuris J, Nikolakakis I, Ibric S, Djuric Z, Kachrimanis K. Preparation of carbamazepine–Soluplus® solid dispersions by hot-melt extrusion, and prediction of drug–polymer miscibility by thermodynamic model fitting. Eur J Pharm Biopharm. 2013;84(1):228–37.

Yao X, Borchardt KA, Gui Y, Guzei IA, Zhang GG, Yu L. Surface-enhanced crystal nucleation and polymorph selection in amorphous posaconazole. J Chem Phys. 2022;157(19): 194502.

Moseson DE, Jordan MA, Shah DD, Corum ID, Alvarenga BR Jr, Taylor LS. Application and limitations of thermogravimetric analysis to delineate the hot melt extrusion chemical stability processing window. Int J Pharm. 2020;590: 119916.

Vyazovkin S, Wight CA. Model-free and model-fitting approaches to kinetic analysis of isothermal and nonisothermal data. Thermochim Acta. 1999;340:53–68.

Zheng J, Luan L, Wang H, Xi L, Yao K. Study on ibuprofen/montmorillonite intercalation composites as drug release system. Appl Clay Sci. 2007;36(4):297–301.

Gamble JF, Tobyn M, Zhang S, Zhu A, Šalplachta J, Matula J, et al. Characterization of the morphological nature of hollow spray dried dispersion particles using X-ray submicron-computed tomography. AAPS PharmSciTech. 2021;23(1):40.

Poozesh S, Setiawan N, Arce F, Sundararajan P, Della Rocca J, Rumondor A, et al. Understanding the process-product-performance interplay of spray dried drug-polymer systems through complete structural and chemical characterization of single spray dried particles. Powder Technol. 2017;320:685–95.

Hadinoto K, Zhu K, Tan RB. Drug release study of large hollow nanoparticulate aggregates carrier particles for pulmonary delivery. Int J Pharm. 2007;341(1–2):195–206.

Gamble JF, Ferreira AP, Tobyn M, DiMemmo L, Martin K, Mathias N, et al. Application of imaging based tools for the characterisation of hollow spray dried amorphous dispersion particles. Int J Pharm. 2014;465(1–2):210–7.

Broadhead J, Edmond Rouan SK, Rhodes CT. The spray drying of pharmaceuticals. Drug Dev Ind Pharm. 1992;18(11–12):1169–206.

de Araújo JIR, de Moura FL, Soares MF, Nadvorny D, Bedor DCG, Rolim LA, et al. Stability study and oxidative degradation kinetics of posaconazole. Microchem J. 2019;151: 104181.

Sun DD, Lee PI. Evolution of supersaturation of amorphous pharmaceuticals: the effect of rate of supersaturation generation. Mol Pharm. 2013;10(11):4330–46.

Taylor LS, Zhang GG. Physical chemistry of supersaturated solutions and implications for oral absorption. Adv Drug Del Rev. 2016;101:122–42.

Acknowledgements

We would like to acknowledge Dr. Justin Newman for assisting with variable temperature XRD experiments.

Funding

All work described here was funded by Merck Sharp & Dohme LLC, a subsidiary of Merck & Co., Inc., Rahway, NJ, USA.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors (employment by Merck Sharp & Dohme LLC, a subsidiary of Merck & Co., Inc., Rahway, NJ, USA) declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

He, R., Lamm, M.S., Brunskill, A. et al. Impact of Processing Methods on the Physico-chemical Properties of Posaconazole Amorphous Solid Dispersions. Pharm Res 41, 141–151 (2024). https://doi.org/10.1007/s11095-023-03632-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11095-023-03632-8