Abstract

Purpose

Increased tablet anisotropy could lead to increased tablet capping propensity. Tooling design variables such as cup depth could serve as a key player for inducing tablet anisotropy.

Methods

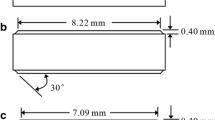

A new capping index (CI) consisting of the ratio of compact anisotropic index (CAI) and material anisotropic index (MAI) is proposed to evaluate tablet capping propensity as a function of punch cup depth. CAI is the ratio of axial to radial breaking force. MAI is the ratio of axial to radial Young’s modulus. The impact of various punch cup depths [flat face, flat face beveled edge, flat face radius edge, standard concave, shallow concave, compound concave, deep concave, and extra deep concave] on the capping propensity of model acetaminophen tablets was studied. Tablets were manufactured at 50, 100, 200, 250, and 300 MPa compression pressure at 20 RPM on different cup depth tools using Natoli NP-RD30 tablet press. A partial least squares model (PLS) was computed to model the impact of the cup depth and compression parameters on the CI.

Results

The PLS model exhibited a positive correlation of increased cup depth to the capping index. The finite elemental analysis confirmed that a high capping tendency with increased cup depth is a direct result of non-uniform stress distribution across powder bed.

Conclusions

Certainly, a proposed new capping index with multivariate statistical analysis gives guidance in selecting tool design and compression parameters for robust tablets.

Similar content being viewed by others

References

Haware RV, Tho I, Bauer-Brandl A. Multivariate analysis of relationships between material properties, process parameters and tablet tensile strength for α-lactose monohydrates. Eur J Pharm Biopharm. 2009;73:424–31.

Narayan P, Hancock BC. The relationship between the particle properties, mechanical behavior, and surface roughness of some pharmaceutical excipient compacts. Materials Sci Eng A Elsevier. 2003;355:24–36.

Anbalagan P, Heng PWS, Liew CV. Tablet compression tooling–impact of punch face edge modification. Int J Pharm Elsevier. 2017;524:373–81.

Akseli I, Hancock BC, Cetinkaya C. Non-destructive determination of anisotropic mechanical properties of pharmaceutical solid dosage forms. Int J Pharm. 2009;377:35–44.

Yu LX, Ellison CD, Conner DP, Lesko LJ, Hussain AS. Influence of drug release properties of conventional solid dosage forms on the systemic exposure of highly soluble drugs. AAPS Pharm Sci. 2001;3:86–92.

Akseli I, Ladyzhynsky N, Katz J, He X. Development of predictive tools to assess capping tendency of tablet formulations. Powder Technol. 2013;236:139–48.

Malamataris S, Hatjichristos T, Rees JE. Apparent compressive elastic modulus and strength isotropy of compacts formed from binary powder mixes. Int J Pharm. 1996;141:101–8.

Hey H, Jorgensen F, Sorensen K, Hasselbalch H, Wamberg T. Oesophageal transit of six commonly used tablets and capsules. BMJ. 1982;285:1717–9.

Feufel MA, Rauwolf G, Meier FC, Karapinar-Çarkit F, Heibges M. Heuristics for designing user-centric drug products: lessons learned from human factors and ergonomics. Br J Clin Pharmacol. 2020;86:1989–99.

Sinka IC, Cunningham JC, Zavaliangos A. Analysis of tablet compaction. II. Finite element analysis of density distributions in convex tablets. J Pharm Sci. 2004;93:2040–53.

Furukawa R, Chen Y, Horiguchi A, Takagaki K, Nishi J, Konishi A, et al. Numerical evaluation of the capping tendency of microcrystalline cellulose tablets during a diametrical compression test. Int J Pharm. 2015;493:182–91.

USP General Chapter. USP 1062 Tablet Compression Characterization. 2020;42(5):1–37

Patel D, Patel VD, Sedlock R, Haware RV. Negative porosity issue in the Heckel analysis: a possible solution. Int J Pharm. 2022;627:122205.

Pitt KG, Newton JM, Stanley P. Tensile fracture of doubly-convex cylindrical discs under diametral loading. J Mater Sci. 1988;23:2723–8.

Holman LE, Leuenberger H. The relationship between solid fraction and mechanical properties of compacts - the percolation theory model approach. Int J Pharm. 1988;46:35–44.

Patel DB, Patel VD, Patel Y, Sturgis JC, Sedlock R, Haware RV. Compression–decompression modulus (CDM)–an alternative/complementary approach to Heckel’s analysis. Pharm Dev Technol Taylor Francis. 2022;27:805–15.

Haware RV, Dave VS, Kakarala B, Delaney S, Staton S, Munson E, et al. Vegetable-derived magnesium stearate functionality evaluation by DM3 approach. Eur J Pharm Sci. 2016;89:115–24.

Patel VD, Rathod V, Haware RV, Stagner WC. Optimized L-SNEDDS and spray-dried S-SNEDDS using a linked QbD-DM3 rational design for model compound ketoprofen. Int J Pharm Elsevier. 2023;631:122494.

Martens H, Martens M. Modified Jack-knife estimation of parameter uncertainty in bilinear modelling by partial least squares regression (PLSR). Food Qual Prefer. 2000;11:5–16.

Han LH, Elliott JA, Bentham AC, Mills A, Amidon GE, Hancock BC. A modified Drucker-Prager cap model for die compaction simulation of pharmaceutical powders. Int J Solids Struct. 2008;45:3088–106.

Nyström C, Karehill P-G. The importance of intermolecular bonding forces and the concept of bonding surface area. Drugs Pharm Sci. 1996;71:17–54.

Abdel-Hamid S, Betz G. Investigating the effect of punch geometry on high speed tableting through radial die-wall pressure monitoring. Pharm Dev Technol. 2013;18:46–54.

Kadiri MS, Michrafy A. The effect of punch’s shape on die compaction of pharmaceutical powders. Powder Technol Elsevier. 2013;239:467–77.

Paul S, Sun CC. Gaining insight into tablet capping tendency from compaction simulation. Int J Pharm. 2017;524:111–20.

Basim P, Haware RV, Dave RH. Tablet capping predictions of model materials using multivariate approach. Int J Pharm. 2019;569:118548.

Natoli D, Levin M, Tsygan L, Liu L. Development, Optimization, and scale-up of process parameters. Developing Solid Oral Dosage Forms Elsevier. 2017:917–51.

Sugimori K, Mori S, Kawashima Y. Characterization of die wall pressure to predict capping of flat- or convex-faced drug tablets of various sizes. Powder Technol. 1989;58:259–64.

Funding

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

None.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

ESM 1

(DOCX 1038 kb)

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Patel, V.D., Patel, D.B., Sturgis, J.C. et al. Assessing the Impact of Punch Geometries on Tablet Capping Using a Newly Proposed Capping Index. Pharm Res 40, 2935–2945 (2023). https://doi.org/10.1007/s11095-023-03555-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11095-023-03555-4