Abstract

Purpose

We aim to perform a systematic study of the time consolidation effect, i.e. the reduction of powder flowability resulting from at-rest storage, on a diverse array of pharmaceutical powders under different stress, humidity, and length of time.

Methods

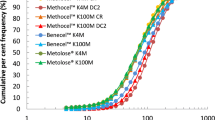

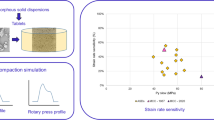

A ring shear cell-based methodology was employed. An instantaneous flow function was obtained, followed immediately by at-rest consolidation at precisely controlled humidity, stress, and duration. The consolidated powder was then subjected to shear-cell measurement. The difference in flowability between the immediate and consolidated specimens were attributed to the time consolidation effect.

Results

Among the six excipients tested, three exhibited time consolidation at varying extents. Citric acid and starch underwent time consolidation only at high relative humidity (RH = 75%), promoted by vapor condensation and liquid bridge formation. For both materials, the flowability decreased with time, and the extent of time consolidation was not sensitive to the stress applied (0.4–2 kPa). Importantly, mannitol was found to time consolidate under both 50% and 75% RH. Given time, mannitol formed cake, giving rise to flow function below unity. Inverse gas chromatography analysis indicated that mannitol possesses high total surface energy among known pharmaceutical powders.

Conclusion

While time consolidation is prevalent among pharmaceutical powders, most can be mitigated by controlling the RH to below 75%. Notably, for materials possessing high surface energy, such as mannitol, time consolidation could occur at ambient humidity. Therefore, it is desirable to consider in-depth time consolidation evaluation for high surface energy powders, e.g. those subjected to milling or of amorphous nature.

Similar content being viewed by others

Abbreviations

- t 1h :

-

1-hour time point

- t 24h :

-

24-hour time point

- RH0 :

-

Critical relative humidity for deliquescence

- ff c :

-

Flow function

- t 0 :

-

Initial time point

- σ1 :

-

Major principal stress

- σ2 :

-

Minor principal stress

- σpre :

-

Normal stress at pre-consolidation

- σsh :

-

Normal stress at shear-to-failure

- τpre :

-

Shear stress at pre-consolidation

- τsh :

-

Shear stress at shear-to-failure

- ƒc :

-

Unconfined yield strength

References

United States Pharmacopeia <1063> Shear Cell Methodology for Powder Flow Testing. In.; 2016. p. 8348–8359.

Tan G, DAV Morton, Larson I. On the methods to measure powder flow. Curr Pharm Des 2015;21(40):5751–5765.

Schulze D. Powders and bulk solids; 2008.

Leung LY, Mao C, Pieters SR, Yang C-Y. A proposed complete methodology to predict gravity flow obstruction of pharmaceutical powders in drug product manufacturing. J Pharm Sci. 2019;108(1):464–75.

Nauka E, Maurer R, Gonzalez AA, Zhang W, Narang AS, Mao C. Theoretical and experimental evaluation of flow pattern of pharmaceutical powder blends discharged from intermediate bulk containers (IBCs). J Pharm Sci. 2021;110(3):1172–81.

Capece M, Silva KR, Sunkara D, Strong J, Gao P. On the relationship of inter-particle cohesiveness and bulk powder behavior: Flowability of pharmaceutical powders. Int J Pharm. 2016;511(1):178–89.

Yu W, Muteki K, Zhang L, Kim G. Prediction of bulk powder flow performance using comprehensive particle size and particle shape distributions. J Pharm Sci. 2011;100(1):284–93.

Domian E, Poszytek K. Wheat flour flow ability as affected by water activity, storage time and consolidation. International Agrophysics. 2005;19(2).

Teunou E, Fitzpatrick J. Effect of storage time and consolidation on food powder flowability. J Food Eng. 2000;43(2):97–101.

Aguilera J, del Valle J, Karel M. Caking phenomena in amorphous food powders. Trends Food Sci Technol. 1995;6(5):149–55.

Salameh AK, Taylor LS. Deliquescence-induced caking in binary powder blends. Pharm Dev Technol. 2006;11(4):453–64.

Salehi H, Karde V, Hajmohammadi H, Dissanayake S, Larsson SH, Heng JY, Bradley M. Understanding flow properties of mannitol powder at a range of temperature and humidity. Int J Pharm. 2021;596:120244.

ASTM-standard. D6773-02: standard shear test method for bulk solids using the Schulze ring shear tester. ASTM international. In.; 2015.

Voelkel A, Strzemiecka B, Adamska K, Milczewska K. Inverse gas chromatography as a source of physiochemical data. J Chromatogr A. 2009;1216(10):1551–66.

Van Oss C, Good R, Chaudhury M. Additive and nonadditive surface tension components and the interpretation of contact angles. Langmuir. 1988;4(4):884–91.

Katdare A, Chaubal M. Excipient development for pharmaceutical, biotechnology, and drug delivery systems: CRC Press; 2006.

Sing KS. Reporting physisorption data for gas/solid systems with special reference to the determination of surface area and porosity (recommendations 1984). Pure Appl Chem. 1985;57(4):603–19.

Fitzpatrick J, Descamps N. Comparison of a uniaxial force displacement tester with a ring shear tester for assessing powder cake strength. Part Sci Technol. 2013;31(2):199–203.

Röck M, Schwedes J. Investigations on the caking behaviour of bulk solids—macroscale experiments. Powder Technol. 2005;157(1–3):121–7.

Zafar U, Vivacqua V, Calvert G, Ghadiri M, Cleaver JS. A review of bulk powder caking. Powder Technol. 2017;313:389–401.

Das S, Larson I, Young P, Stewart P. Understanding lactose behaviour during storage by monitoring surface energy change using inverse gas chromatography. Dairy Science & Technology. 2010;90(2):271–85.

Das SC, Larson I, Morton DA, Stewart PJ. Determination of the polar and total surface energy distributions of particulates by inverse gas chromatography. Langmuir. 2011;27(2):521–3.

Das SC, Stewart PJ. Characterising surface energy of pharmaceutical powders by inverse gas chromatography at finite dilution. J Pharm Pharmacol. 2012;64(9):1337–48.

Das SC, Zhou Q, Morton DA, Larson I, Stewart PJ. Use of surface energy distributions by inverse gas chromatography to understand mechanofusion processing and functionality of lactose coated with magnesium stearate. Eur J Pharm Sci. 2011;43(4):325–33.

Papirer E, Brendle E, Balard H, Vergelati C. Inverse gas chromatography investigation of the surface properties of cellulose. J Adhes Sci Technol. 2000;14(3):321–37.

Steele DF, Moreton RC, Staniforth JN, Young PM, Tobyn MJ, Edge S. Surface energy of microcrystalline cellulose determined by capillary intrusion and inverse gas chromatography. AAPS J. 2008;10(3):494–503.

Zhou QT, Denman JA, Gengenbach T, Das S, Qu L, Zhang H, Larson I, Stewart PJ, Morton DA. Characterization of the surface properties of a model pharmaceutical fine powder modified with a pharmaceutical lubricant to improve flow via a mechanical dry coating approach. J Pharm Sci. 2011;100(8):3421–30.

Kondor A, Williams D, Burnett D. Determination of Acid-Base component of the surface energy by inverse gas chromatography: iGC SEA application note 227. In. .

Salameh AK, Taylor LS. Deliquescence in binary mixtures. Pharm Res. 2005;22(2):318–24.

Ketkar AB, Keller DV. Adhesion of Micron-sized limestone particles to a massive coal substrate. J Adhes. 1975;7(3):235–51.

Odidi IO, Newton JM, Buckton G. The effect of surface treatment on the values of contact angles measured on a compressed powder surface. Int J Pharm. 1991;72(1):43–9.

Podczeck F. Particle-particle adhesion in pharmaceutical powder handling. London, UK: Imperial College Press; 1998.

Williams R, D. Particle engineering in pharmaceutical solids processing: surface energy considerations. Curr Pharm Des. 2015;21(19):2677–94.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of Interests/Competing Interests

The authors declare that they have no conflicts of interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

ESM 1

(DOCX 13 kb)

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Thool, P., Stancill, C., Bui, M. et al. Evaluation of Time Consolidation Effect of Pharmaceutical Powders. Pharm Res 39, 3345–3357 (2022). https://doi.org/10.1007/s11095-022-03402-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11095-022-03402-y