Abstract

Purpose

Bacteriophage (phage) therapy has re-gained attention lately given the ever-increasing prevalence of multi-drug resistance ‘super-bugs’. To develop therapeutic phage into clinically usable drug products, the strategy of solidifying phage formulations has been implemented to diversify the dosage forms and to overcome the storage condition limitations for liquid phage formulations.

Method

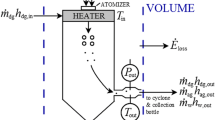

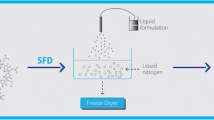

In our work, we hypothesize and tested that an advanced technology, thin film freeze-drying (TFFD), can be used to produce phage containing dry powders without significantly losing phage viability. Here we selected T7 phage as our model phage in a preliminary screening study.

Results

We found that a binary excipient matrix of sucrose and leucine at ratios of 90:10 or 75:25 by weight, protected phage from the stresses encountered during the TFFD process. In addition, we confirmed that incorporating a buffer system in the formulation significantly improved the survival of phage during the initial freezing step and subsequent sublimation step in the solidifying processes. The titer loss of phage in SM buffer (Tris/NaCl/MgSO4) containing formulation was as low as 0.19 log plaque forming units, which indicated that phage function was well preserved after the TFFD process. The presence of buffers markedly reduced the geometric particle sizes as determined by a dry dispersion method using laser diffraction, which indicated that the TFFD phage powder formulations were easily sheared into smaller powder aggregates, an ideal property for facilitating a variety of topical drug delivery routes including pulmonary delivery through dry powder inhalers, nebulization after reconstitution, and intranasal or wound therapy, etc.

Conclusion

From these findings, we show that introducing buffer system can stabilize phage during dehydration processes, and TFFD, as a novel particle engineering method, can successfully produce phage containing powders that possess the desired properties for bioactivity and potentially for inhalation therapy.

Similar content being viewed by others

References

Prevention CfDCa. Biggest Threats and Data -- 2019 AR Threats Report. Available from: https://www.cdc.gov/drugresistance/biggest-threats.html.

Kingwell K. Bacteriophage therapies re-enter clinical trials. Nat Rev Drug Discov. 2015;14(8):515–6.

Boucher HW, Talbot Gh Fau - Bradley JS, Bradley Js Fau - Edwards JE, Edwards Je Fau - Gilbert D, Gilbert D Fau - Rice LB, Rice Lb Fau - Scheld M, Scheld M Fau - Spellberg B, Spellberg B Fau - Bartlett J, Bartlett J. Bad bugs, no drugs: no ESKAPE! An update from the Infectious Diseases Society of America. (1537–6591 (Electronic)).

Cars O, Hogberg Ld Fau - Murray M, Murray M Fau - Nordberg O, Nordberg O Fau - Sivaraman S, Sivaraman S Fau - Lundborg CS, Lundborg Cs Fau - So AD, So Ad Fau - Tomson G, Tomson G. Meeting the challenge of antibiotic resistance. (1756–1833 (Electronic)).

Salmond GP, Fineran PC. A century of the phage: past, present and future. Nat Rev Microbiol. 2015;13(12):777–86.

Zhang Y, Zhang H, Ghosh D. The stabilizing excipients in dry state therapeutic phage formulations. AAPS PharmSciTech. 2020;21(4):133.

Ohtake S, Kita Y, Arakawa T. Interactions of formulation excipients with proteins in solution and in the dried state. Adv Drug Deliv Rev. 2011;63(13):1053–73.

Frokjaer S, Otzen DE. Protein drug stability: a formulation challenge. Nat Rev Drug Discovery. 2005;4(4):298–306.

Mascarell J, Ryan M. Technical aspects of enzyme utilization: Dry vs liquid enzymes. In: Morand-Fehr P, editor. Feed manufacturing in Southern Europe: New challenges: Zaragoza : CIHEAM; 1997. p. 161–174.

Carpenter JF, Chang BS, Garzon-Rodriguez W, Randolph TW. Rational design of stable lyophilized protein formulations: theory and practice. Pharm Biotechnol. 2002;13:109–33.

Chang RYK, Wallin M, Kutter E, Morales S, Britton W, Li J, Chan H-K. Storage stability of inhalable phage powders containing lactose at ambient conditions. Int J Pharm. 2019;560:11–8.

Lin Y, Yoon Kyung Chang R, Britton WJ, Morales S, Kutter E, Li J, Chan HK. Storage stability of phage-ciprofloxacin combination powders against Pseudomonas aeruginosa respiratory infections. Int J Pharm. 2020;591:119952.

Ly A, Carrigy NB, Wang H, Harrison M, Sauvageau D, Martin AR, Vehring R, Finlay WH. Atmospheric spray freeze drying of sugar solution with phage D29. Front Microbiol. 2019;10:488.

Leung SS, Parumasivam T, Nguyen A, Gengenbach T, Carter EA, Carrigy NB, Wang H, Vehring R, Finlay WH, Morales S. Effect of storage temperature on the stability of spray dried bacteriophage powders. Eur J Pharm Biopharm. 2018;127:213–22.

Leung SS, Parumasivam T, Gao FG, Carter EA, Carrigy NB, Vehring R, Finlay WH, Morales S, Britton WJ, Kutter E. Effects of storage conditions on the stability of spray dried, inhalable bacteriophage powders. Int J Pharm. 2017;521(1–2):141–9.

Vandenheuvel D, Singh A, Vandersteegen K, Klumpp J, Lavigne R, Van den Mooter G. Feasibility of spray drying bacteriophages into respirable powders to combat pulmonary bacterial infections. Eur J Pharm Biopharm. 2013;84(3):578–82.

Golshahi L, Lynch K, Dennis J, Finlay W. In vitro lung delivery of bacteriophages KS4-M and ΦKZ using dry powder inhalers for treatment of Burkholderia cepacia complex and Pseudomonas aeruginosa infections in cystic fibrosis. J Appl Microbiol. 2011;110(1):106–17.

Zhang Y, Peng X, Zhang H, Watts AB, Ghosh D. Manufacturing and ambient stability of shelf freeze dried bacteriophage powder formulations. Int J Pharm. 2018;542(1):1–7.

Chang RY, Wong J, Mathai A, Morales S, Kutter E, Britton W, Li J, Chan H-K. Production of highly stable spray dried phage formulations for treatment of Pseudomonas aeruginosa lung infection. Eur J Pharm Biopharm. 2017;121:1–13.

Engstrom JD, Lai ES, Ludher BS, Chen B, Milner TE, Williams RO, Kitto GB, Johnston KP. Formation of stable submicron protein particles by thin film freezing. Pharm Res. 2008;25(6):1334–46.

Overhoff K, Johnston K, Tam J, Engstrom J, Williams R III. Use of thin film freezing to enable drug delivery: a review. J Drug Delivery Sci Technol. 2009;19(2):89–98.

Johnston KP, Engstrom J, Tam J. Templated open flocs of anisotropic particles for enhanced pulmonary delivery. In.: Google Patents; 2009.

Li X, Thakkar SG, Ruwona TB, Williams RO 3rd, Cui Z. A method of lyophilizing vaccines containing aluminum salts into a dry powder without causing particle aggregation or decreasing the immunogenicity following reconstitution. J Control Release. 2015;204:38–50.

Thakkar SG, Ruwona TB, Williams RO 3rd, Cui Z. The immunogenicity of thin-film freeze-dried, aluminum salt-adjuvanted vaccine when exposed to different temperatures. Hum Vaccin Immunother. 2017;13(4):936–46.

Leung SS, Parumasivam T, Gao FG, Carrigy NB, Vehring R, Finlay WH, Morales S, Britton WJ, Kutter E, Chan H-K. Production of inhalation phage powders using spray freeze drying and spray drying techniques for treatment of respiratory infections. Pharm Res. 2016;33(6):1486–96.

Mumenthaler M, Leuenberger H. Atmospheric spray-freeze drying: a suitable alternative in freeze-drying technology. Int J Pharm. 1991;72(2):97–110.

Dini C, de Urraza PJ. Effect of buffer systems and disaccharides concentration on Podoviridae coliphage stability during freeze drying and storage. Cryobiology. 2013;66(3):339–42.

SM buffer. Cold Spring Harbor Protocols. 2006;2006(1):pdb.rec8111.

E.I. K. Bragg's Law and Diffraction: How waves reveal the atomic structure of crystal.

Lamy B, Serrano DR, O’connell P, Couet W, Marchand S, Healy AM, Tewes F. Use of leucine to improve aerodynamic properties of ciprofloxacin-loaded maltose microparticles for inhalation. Eur J Pharm Res. 2019;1(1):2–11.

Merabishvili M, Vervaet C, Pirnay J-P, De Vos D, Verbeken G, Mast J, Chanishvili N, Vaneechoutte M. Stability of Staphylococcus aureus phage ISP after freeze-drying (lyophilization). PloS one. 2013;8(7):e68797.

Matinkhoo S, Lynch KH, Dennis JJ, Finlay WH, Vehring R. Spray-dried respirable powders containing bacteriophages for the treatment of pulmonary infections. J Pharm Sci. 2011;100(12):5197–205.

Larsen S. Studies on stability of drugs in frozen systems. VI. The effect of freezing upon pH for buffered aqueous solutions. Arch Pharm Chem Sci Ed. 1973;1:41–53.

Wu C, Shamblin S, Varshney D, Shalaev E. Advance understanding of buffer behavior during lyophilization. In. Lyophilized Biologics and Vaccines: Springer; 2015. p. 25–41.

Kolhe P, Amend E, K. Singh S. Impact of freezing on pH of buffered solutions and consequences for monoclonal antibody aggregation. Biotechnology progress. 2010;26(3):727–733.

Chang BS, Randall CS. Use of subambient thermal analysis to optimize protein lyophilization. Cryobiology. 1992;29(5):632–56.

pH vs Temperature for Tris Buffer. New England Biolabs Inc.; Available from: https://www.neb.com/tools-and-resources/usage-guidelines/ph-vs-temperature-for-tris-buffer.

Whitman P, Marshall R. Characterization of two psychrophilic Pseudomonas bacteriophages isolated from ground beef. Appl Microbiol. 1971;22(3):463–8.

Lark KG, Adams MH. The stability of phages as a function of the ionic environment. In.Cold Spring Harbor symposia on quantitative biology: Cold Spring Harbor Laboratory Press; 1953. p. 171–183.

Adams MH. The stability of bacterial viruses in solutions of salts. J Gen Physiol. 1949;32(5):579–94.

Mylon SE, Rinciog CI, Schmidt N, Gutierrez L, Wong GCL, Nguyen TH. Influence of salts and natural organic matter on the stability of bacteriophage MS2. Langmuir. 2010;26(2):1035–42.

Whang T, Daly B, Yin J. Metal-ion discrimination by phage T7. J Inorg Biochem. 1996;63(1):1–7.

Pikal-Cleland KA, Carpenter JF. Lyophilization-induced protein denaturation in phosphate buffer systems: monomeric and tetrameric β-galactosidase. J Pharm Sci. 2001;90(9):1255–68.

Wang Y-B, Watts AB, Peters JI, Liu S, Batra A, Williams RO 3rd. In vitro and in vivo performance of dry powder inhalation formulations: comparison of particles prepared by thin film freezing and micronization. AAPS PharmSciTech. 2014;15(4):981–93.

Wong J, Kwok PCL, Noakes T, Fathi A, Dehghani F, Chan H-K. Effect of crystallinity on electrostatic charging in dry powder inhaler formulations. Pharm Res. 2014;31(7):1656–64.

Shetty N, Zeng L, Mangal S, Nie H, Rowles MR, Guo R, Han Y, Park JH, Zhou Q. Effects of moisture-induced crystallization on the aerosol performance of spray dried amorphous ciprofloxacin powder formulations. Pharm Res. 2018;35(1):7.

Chang RYK, Kwok PCL, Khanal D, Morales S, Kutter E, Li J, Chan H-K. Inhalable bacteriophage powders: glass transition temperature and bioactivity stabilization. Bioeng Transl Med. 2020;5(2):e10159–e10159.

Acknowledgements

Zhang and Williams acknowledge TFF Pharmaceuticals, Inc. for the financial support through a sponsored research agreement. Ghosh and Soto were supported by NIH National Heart, Lung and Blood Institute of the National Institutes of Health under award number R01HL138251. All authors are co-inventors on related intellectual property. The Board of Regents of The University of Texas has licensed IP related to research reported in this paper to TFF Pharmaceuticals, Inc. Williams acknowledges consulting for and ownership of stock in TFF Pharmaceuticals, Inc.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhang, Y., Soto, M., Ghosh, D. et al. Manufacturing Stable Bacteriophage Powders by Including Buffer System in Formulations and Using Thin Film Freeze-drying Technology. Pharm Res 38, 1793–1804 (2021). https://doi.org/10.1007/s11095-021-03111-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11095-021-03111-y