Abstract

Purpose

To investigate how excipient matrix affects punch sticking propensity of active pharmaceutical ingredients (API), with the focus on the effect of bonding interactions between API-API (F2) and API-excipient (F3).

Method

Sticking kinetics of direct compression formulations, consisting of 20% of celecoxib (CEL) or ibuprofen (IBN) in different excipient matrices, i.e., microcrystalline cellulose (Avicel PH102 and Avicel PH105 dry coated with nano-sized silica (PH105(n)), hypromellose (K15 M), and a 3:1 mixture between starch and Avicel PH102 (S3P1), was assessed using a removable punch tip on a compaction simulator. The amount of material transferred to punch was determined gravimetrically every 10 compressions up to 50 compactions.

Results

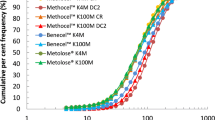

CEL exhibited higher F2 than IBN. CEL also exhibited more sticking under otherwise identical compaction conditions in the same excipient matrix. Among different excipient matrices, sticking propensity of both APIs followed the ascending order: PH105(n) < PH102 < K15 M < S3P1. This order was exactly opposite to the order of F3, confirming that greater bonding strength of the formulation favors lower sticking propensity of a given API.

Conclusion

For an API prone to punch sticking, judicious use of excipients to render higher tablet mechanical strength can mitigate severity of punch sticking.

Similar content being viewed by others

Abbreviations

- F2:

-

API-API cohesive interaction

- F3:

-

API-excipient adhesive interaction

- CEL:

-

Celecoxib

- εc :

-

Critical porosity

- F4:

-

Excipient-excipient cohesive interaction

- HPMC:

-

Hydroxypropyl methyl cellulose

- IBN:

-

Ibuprofen

- MCC:

-

Microcrystalline cellulose

- 1/C:

-

Plasticity parameter

- F1:

-

Punch-API adhesive interaction

- S3P1:

-

Starch + MCC (3:1)

- σ:

-

Tablet tensile strength

- σ0 :

-

Tensile strength at zero porosity

References

Abdel-Hamid S, Betz G. A novel tool for the prediction of tablet sticking during high speed compaction. Pharm Dev Technol. 2012;17(6):747–54.

Otsuka A. Adhesive properties and related phenomena for powdered pharmaceuticals. Yakugaku Zasshi. 1998;118(4):127–42.

Al-Karawi C, Lukášová I, Sakmann A, Leopold CS. Novel aspects on the direct compaction of ibuprofen with special focus on sticking. Powder Technol. 2017;317(Supplement C):370–80.

McDermott TS, Farrenkopf J, Hlinak A, Neilly JP, Sauer D. A material sparing method for quantitatively measuring tablet sticking. Powder Technol. 2011;212(1):240–52.

Paul S, Taylor LJ, Murphy B, Krzyzaniak JF, Dawson N, Mullarney MP, et al. Powder properties and compaction parameters that influence punch sticking propensity of pharmaceuticals. Int J Pharm. 2017;521(1–2):374–83.

Waknis V, Chu E, Schlam R, Sidorenko A, Badawy S, Yin S, et al. Molecular basis of crystal morphology-dependent adhesion behavior of mefenamic acid during tableting. Pharm Res. 2014;31(1):160–72.

Paul S, Wang K, Taylor LJ, Murphy B, Krzyzaniak J, Dawson N, et al. Dependence of punch sticking on compaction pressure-roles of particle deformability and tablet tensile strength. J Pharm Sci. 2017;106(8):2060–7.

Hooper D, Clarke FC, Docherty R, Mitchell JC, Snowden MJ. Effects of crystal habit on the sticking propensity of ibuprofen—A case study. Int J Pharm. 2017;531(1):266–75.

Tsosie H, Thomas J, Strong J, Zavaliangos A. Scanning electron microscope observations of powder sticking on punches during a limited number (N < 5) of compactions of acetylsalicylic acid. Pharm Res. 2017;34(10):2012–24.

Corn M. The adhesion of solid particles to solid surfaces. II. J Air Pollut Control Assoc. 1961;11(12):566–84.

Corn M. The adhesion of solid particles to solid surfaces, I. a review. J Air Pollut Control Assoc. 1961;11(11):523–8.

Roberts M, Ford JL, MacLeod GS, Fell JT, Smith GW, Rowe PH. Effects of surface roughness and chrome plating of punch tips on the sticking tendencies of model ibuprofen formulations. J Pharm Pharmacol. 2003;55(9):1223–8.

Roberts M, Ford JL, MacLeod GS, Fell JT, Smith GW, Rowe PH, et al. Effect of punch tip geometry and embossment on the punch tip adherence of a model ibuprofen formulation. J Pharm Pharmacol. 2004;56(7):947–50.

Samiei L, Kelly K, Taylor L, Forbes B, Collins E, Rowland M. The influence of electrostatic properties on the punch sticking propensity of pharmaceutical blends. Powder Technol. 2017;305(Supplement C):509–17.

Al-Karawi C, Kaiser T, Leopold CS. A novel technique for the visualization of tablet punch surfaces: characterization of surface modification, wear and sticking. Int J Pharm. 2017;530(1):440–54.

Reed K, Davies C, Kelly K. Tablet sticking: using a ‘compression toolbox’ to assess multiple tooling coatings options. Powder Technol. 2015;285(Supplement C):103–9.

Paul S, Taylor LJ, Murphy B, Krzyzaniak J, Dawson N, Mullarney MP, et al. Mechanism and kinetics of punch sticking of pharmaceuticals. J Pharm Sci. 2017;106(1):151–8.

Uchimoto T, Iwao Y, Yamamoto T, Sawaguchi K, Moriuchi T, Noguchi S, et al. Newly developed surface modification punches treated with alloying techniques reduce sticking during the manufacture of ibuprofen tablets. Int J Pharm. 2013;441(1–2):128–34.

Chattoraj S, Shi L, Sun CC. Profoundly improving flow properties of a cohesive cellulose powder by surface coating with nano-silica through comilling. J Pharm Sci. 2011;100(11):4943–52.

Kuentz M, Leuenberger H. Pressure susceptibility of polymer tablets as a critical property: a modified Heckel equation. J Pharm Sci. 1999;88(2):174–9.

Sun CC. Microstructure of tablet—pharmaceutical significance, assessment, and engineering. Pharm Res. 2017;34(5):918–28.

Paul S, Sun CC. The suitability of common compressibility equations for characterizing plasticity of diverse powders. Int J Pharm. 2017;532:124–30.

Sun CC. A novel method for deriving true density of pharmaceutical solids including hydrates and water-containing powders. J Pharm Sci. 2004;93(3):646–53.

Sun CC. True density of microcrystalline cellulose. J Pharm Sci. 2005;94(10):2132–4.

Sun CC. Mechanism of moisture induced variations in true density and compaction properties of microcrystalline cellulose. Int J Pharm. 2008;346(1–2):93–101.

Chang SY, Sun CC. Superior plasticity and tabletability of theophylline monohydrate. Mol Pharm. 2017;14(6):2047–55.

Sun CC. Quantifying errors in tableting data analysis using the Ryshkewitch equation due to inaccurate true density. J Pharm Sci. 2005;94(9):2061–8.

Paul S, Chang SY, Sun CC. The phenomenon of tablet flashing its impact on tableting data analysis and a method to eliminate it. Powder Technol. 2017;305:117–24.

Fell JT, Newton JM. Determination of tablet strength by the diametral-compression test. J Pharm Sci. 1970;59(5):688–91.

Ryshkewitch E. Compression strength of porous sintered alumina and zirconia. J Am Cerac Soc. 1953;36(2):65–8.

Osei-Yeboah F, Sun CC. A pitfall in analyzing powder compactibility data using nonlinear regression. J Pharm Sci. 2013;102(3):1135–6.

Shi L, Sun CC. Transforming powder mechanical properties by core/shell structure: compressible sand. J Pharm Sci. 2010;99:4458–62.

Tye CK, Sun CC, Amidon GE. Evaluation of the effects of tableting speed on the relationships between compaction pressure, tablet tensile strength, and tablet solid fraction. J Pharm Sci. 2005;94(3):465–72.

Sun CC. Decoding powder tabletability: roles of particle adhesion and plasticity. J Adhes Sci Technol. 2011;25(4–5):483–99.

Osei-Yeboah F, Chang SY, Sun CC. A critical examination of the phenomenon of bonding Area - bonding strength interplay in powder tableting. Pharm Res. 2016;33(5):1126–32.

Osei-Yeboah F, Lan Y, Sun CC. A top coating strategy with highly bonding polymers to enable direct tableting of multiple unit pellet system (MUPS). Powder Technol. 2017;305:591–6.

Swaminathan S, Ramey B, Hilden J, Wassgren C. Characterizing the powder punch-face adhesive interaction during the unloading phase of powder compaction. Powder Technol. 2017;315:410–21.

Perumalla SR, Shi L, Sun CC. Ionized form of acetaminophen with improved compaction properties. CrystEngComm. 2012;14(7):2389–90.

Alderborn G, Nystrom C. Radial and axial tensile strength and strength variability of paracetamol tablets. Acta Pharm Suec. 1984;21(1):1–8.

Wu CY, Ruddy OM, Bentham AC, Hancock BC, Best SM, Elliott JA. Modelling the mechanical behaviour of pharmaceutical powders during compaction. Powder Technol. 2005;52(1–3):107–17.

Patel S, Sun CC. Macroindentation hardness measurement-modernization and applications. Int J Pharm. 2016;506(1–2):262–7.

Rowe RC, Sheskey PJ, Quinn ME. Handbook of pharmaceutical excipients, 6th edn. 2009.

Cui Y. A material science perspective of pharmaceutical solids. Int J Pharm. 2007;339:3–18.

Heng PWS, Chan LW, Easterbrook MG, Li X. Investigation of the influence of mean HPMC particle size and number of polymer particles on the release of aspirin from swellable hydrophilic matrix tablets. J Control Release. 2001;76(1):39–49.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

ESM 1

(DOCX 152 kb)

Rights and permissions

About this article

Cite this article

Paul, S., Sun, C.C. Modulating Sticking Propensity of Pharmaceuticals Through Excipient Selection in a Direct Compression Tablet Formulation. Pharm Res 35, 113 (2018). https://doi.org/10.1007/s11095-018-2396-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11095-018-2396-3