Abstract

Purpose

To systematically assess the dependence of friability on tablet mechanical properties, compaction pressure, and tablet porosity.

Methods

Several common excipients and their mixtures exhibiting diverse mechanical properties were analyzed. Tablet elastic modulus, hardness, brittleness, porosity, and tensile strength were determined using standard techniques and then were correlated to tablet friability both individually and as a group to derive a universal model.

Results

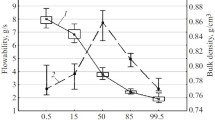

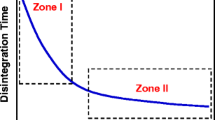

Viscoelastic starch exhibits the highest friability followed by brittle excipients (mannitol, DCPA, and LM) and then ductile excipients (HPC and MCC). A reasonably accurate model for predicting pharmaceutically relevant range of friability, up to 3%, of binary mixtures is presented based on friability of individual components. In addition, a multivariate model between friability and different mechanical parameters was developed, based on which the weight loss propensity of tablets may be predicted.

Conclusions

The experimental findings and predictive model are useful for expedited development and optimization of tablet formulation using a minimum amount of API.

Similar content being viewed by others

Abbreviations

- ε:

-

Porosity

- σ:

-

Tablet tensile strength

- DCPA:

-

Dicalcium phosphate anhydrate

- E :

-

Tablet elastic modulus

- Fr :

-

Friability

- H:

-

Indentation hardness

- HPC:

-

Hydroxypropyl cellulose

- KIc :

-

Stress intensity factor

- LM:

-

Lactose monohydrate

- MCC:

-

Microcrystalline cellulose

- TBI:

-

Tablet brittleness index

References

Dexheimer SL. Terahertz Spectroscopy: Principles and Applications. Boca Raton: CRC Press; 2007.

Seitavuopio P, Heinamaki J, Rantanen J, Yliruusi J. Monitoring tablet surface roughness during the film coating process. AAPS PharmSciTech. 2006;7:E31.

USP. USP37/NF32 (Online), General Chapters. Tablet Friability. Rockville: United States Pharmacopoeial Convention; 2014.

Osei-Yeboah F, Sun CC. Validation and applications of an expedited tablet friability method. Int J Pharm. 2015;484:146–55.

Perumalla SR, Paul S, Sun CC. Enabling the Tablet Product Development of 5-Fluorocytosine by Conjugate Acid Base Cocrystals. J Pharm Sci. 2016;105:1960–6.

Ghadiri M, Zhang Z. Impact attrition of particulate solids. Part 1: A theoretical model of chipping. Chem Eng Sci. 2002;57:3659–69.

Bharadwaj R, Smith C, Hancock BC. The coefficient of restitution of some pharmaceutical tablets/compacts. Int J Pharm. 2010;402:50–6.

Kodam M. Attrition of pharmaceutical tablets. Doctoral dissertation: Purdue University; 2010.

Gong XC, Sun CC. A new tablet brittleness index. Eur J Pharm Biopharm. 2015;93:260–6.

Archard JF. Contact and Rubbing of Flat Surfaces. J Appl Phys. 1953;24:981–8.

Duncan-Hewitt WC. Predicting the Relative Rate of Wear of Pharmaceutical Compacts Using the Mechanical-Properties of Their Constituent Crystals. Powder Technol. 1990;60:265–72.

Sun CC. A novel method for deriving true density of pharmaceutical solids including hydrates and water-containing powders. J Pharm Sci. 2004;93:646–53.

Kuentz M, Leuenberger H. Pressure susceptibility of polymer tablets as a critical property: A modified Heckel equation. J Pharm Sci. 1999;88:174–9.

Fell JT, Newton JM. Determination of tablet strength by the diametral-compression test. J Pharm Sci. 1970;59:688–91.

Gong XC, Chang SY, Osei-Yeboah F, Paul S, Perumalla SR, Shi LM, et al. Dependence of tablet brittleness on tensile strength and porosity. Int J Pharm. 2015;493:208–13.

Patel S, Sun CC. Macroindentation hardness measurement-Modernization and applications. Int J Pharm. 2016;506:262–7.

CY W, Best SM, Bentham AC, Hancock BC, Bonfield W. A simple predictive model for the tensile strength of binary tablets. Eur J Pharm Sci. 2005;25:331–6.

Paul S, Sun CC. Lubrication with magnesium stearate increases tablet brittleness. Powder Technol. 2017;309:126–32.

Sun CC. Microstructure of tablet—pharmaceutical Significance, assessment, and engineering. Pharm Res. 2017;34:918–28.

Paul S, Sun CC. The suitability of common compressibility equations for characterizing plasticity of diverse powders. Int J Pharm. 2017;532:124–30.

Hornbogen E. The role of fracture toughness in the wear of metals. Wear. 1975;33(2):251–9.

Lawn BR, Marshall DB. Hardness, Toughness, and Brittleness: An Indentation Analysis. J Am Ceram Soc. 1979;62:347–50.

Michrafy A, Michrafy M, Kadiri MS, Dodds JA. Predictions of tensile strength of binary tablets using linear and power law mixing rules. Int J Pharm. 2007;333:118–26.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

ESM 1

(DOCX 80 kb)

Rights and permissions

About this article

Cite this article

Paul, S., Sun, C.C. Dependence of Friability on Tablet Mechanical Properties and a Predictive Approach for Binary Mixtures. Pharm Res 34, 2901–2909 (2017). https://doi.org/10.1007/s11095-017-2273-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11095-017-2273-5