ABSTRACT

Purpose

Surface area and surface energy of pharmaceutical powders are affected by milling and may influence formulation, performance and handling. This study aims to decouple the contribution of surface area and surface energy, and to quantify each of these factors, on cohesion.

Methods

Mefenamic acid was processed by cryogenic milling. Surface energy heterogeneity was determined using a Surface Energy Analyser (SEA) and cohesion measured using a uniaxial compression test. To decouple the surface area and surface energy contributions, milled mefenamic acid was “normalised” by silanisation with methyl groups, confirmed using X-ray Photoelectron Spectroscopy.

Results

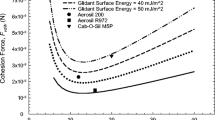

Both dispersive and acid–base surface energies were found to increase with increasing milling time. Cohesion was also found to increase with increasing milling time. Silanised mefenamic acid possessed a homogenous surface with a surface energy of 33.1 ± 1.4 mJ/m2 , for all milled samples. The cohesion for silanised mefenamic acid was greatly reduced, and the difference in the cohesion can be attributed solely to the increase in surface area. For mefenamic acid, the contribution from surface energy and surface area on cohesion was quantified to be 57% and 43%, respectively.

Conclusions

Here, we report an approach for decoupling and quantifying the contribution from surface area and surface energy on powder cohesion.

Similar content being viewed by others

Abbreviations

- BET:

-

Brunauer Emmett, Teller model for calculating surface area from gas adsorption isotherms

- iGC:

-

Inverse gas chromatography

- RH:

-

Relative humidity

- SEA:

-

Surface area analyser

- SEM:

-

Scanning electron microscopy

- vOCG:

-

van Oss Chaudhury, Good method for calculation of acid–base surface energy

- XPS:

-

X-ray photoelectron spectroscopy

References

Fichtner F, Mahlin D, Welch K, Gaisford S, Alderborn G. Effect of surface energy on powder compactibility. Pharm Res. 2008;25(12):2750–9.

Castellanos A. The relationship between attractive interparticle forces and bulk behaviour in dry and uncharged fine powders. Adv Phys. 2005;54(4):263–376.

Kumar A, Staedler T, Jiang X. Role of relative size of asperities and adhering particles on the adhesion force. J Colloid Interface Sci. 2013;409:211–8.

Podczeck F, Mia Y. The influence of particle size and shape on the angle of internal friction and the flow factor of unlubricated and lubricated powders. Int J Pharm. 1996;144(2):187–94.

Rasenack N, Müller BW. Crystal habit and tableting behavior. Int J Pharm. 2002;244(1–2):45–57.

Kaerger JS, Edge S, Price R. Influence of particle size and shape on flowability and compactibility of binary mixtures of paracetamol and microcrystalline cellulose. Eur J Pharm Sci. 2004;22(2–3):173–9.

Lam KK, Newton JM. Influence of particle size on the adhesion behaviour of powders, after application of an initial press-on force. Powder Technol. 1992;73(2):117–25.

Heng JYY, Bismarck A, Williams DR. Anisotropic surface chemistry of crystalline pharmaceutical solids. AAPS PharmSciTech. 2006;7(4):12–20.

Planins̄ek O, Zadnik J, Kunaver M, Src̄ic̄ S, Godec A. Structural evolution of indomethacin particles upon milling: time-resolved quantification and localization of disordered structure studied by IGC and DSC. J Pharm Sci. 2010;99(4):1968–81.

Smith AP, Shay JS, Spontak RJ, Balik CM, Ade H, Smith SD, et al. High-energy mechanical milling of poly (methyl methacrylate), polyisoprene and poly (ethylene-alt-propylene). Polym J. 2000;41(16):6271–83.

Wong LW, Pilpel N. The effect of particle shape on the mechanical properties of powders. Int J Pharm. 1990;59(2):145–54.

Farley R, Valentin FHH. Effect of particle size upon the strength of powders. Powder Technol. 1968;1(6):344–54.

Heng JYY, Williams DR. Wettability of paracetamol polymorphic forms I and II. Langmuir. 2006;22(16):6905–9.

Heng JYY, Bismarck A, Lee AF, Wilson K, Williams DR. Anisotropic surface chemistry of aspirin crystals. J Pharm Sci. 2007;96(8):2134–44.

Ho R, Heng JYY, Dilworth SE, Williams DR. Wetting behavior of ibuprofen racemate surfaces. J Adhes. 2008;84(6):483–501.

Ho R, Hinder SJ, Watts JF, Dilworth SE, Williams DR, Heng JYY. Determination of surface heterogeneity of d-mannitol by sessile drop contact angle and finite concentration inverse gas chromatography. Int J Pharm. 2010;387(1–2):79–86.

Heng JYY, Thielmann F, Williams DR. The effects of milling on the surface properties of form I paracetamol crystals. Pharm Res. 2006;23(8):1918–27.

Ho R, Naderi M, Heng JYY, Williams DR, Thielmann F, Bouza P, et al. Effect of milling on particle shape and surface energy heterogeneity of needle-shaped crystals. Pharm Res. 2012;29(10):2806–16.

Thielmann F, Burnett DJ, Heng JYY. Determination of the surface energy distributions of different processed lactose. Drug Dev Ind Pharm. 2007;33(11):1240–53.

Das SC, Stewart PJ. Characterising surface energy of pharmaceutical powders by inverse gas chromatography at finite dilution. J Pharm Pharmacol. 2012;64(9):1337–48.

Al-Chalabi SAM, Jones AR, Luckham PF. A simple method for improving the dispersability of micron-sized solid spheres. J Aerosol Sci. 1990;21(6):821–6.

Schultz J, Lavielle L, Martin C. The role of the interface in carbon fibre-epoxy composites. J Adhes. 1987;23(1):45–60.

Van Oss CJ, Chaudhury MK, Good RJ. Interfacial Lifshitz-van der Waals and polar interactions in macroscopic systems. Chem Rev. 1988;88(6):927–41.

Das SC, Larson I, Morton DAV, Stewart PJ. Determination of the polar and total surface energy distributions of particulates by inverse gas chromatography. Langmuir. 2010;27(2):521–3.

Fowkes FM. Determination of interfacial tensions, contact angles, and dispersion forces in surfaces by assuming additivity of intermolecular interactions in surfaces. J Phys Chem. 1962;66(2):382.

Owens DK, Wendt RC. Estimation of the surface free energy of polymers. J Appl Polym Sci. 1969;13(8):1741–7.

Etzler FM. Characterisation of surface free energies and surface chemistry of solids. In: Mittal KL, editor. Contact angle, wettability and adhesion. Utrecht, The Netherlands: VSP; 2003. p. 219–63.

Dorris GM, Gray DG. Adsorption of n-alkanes at zero surface coverage on cellulose paper and wood fibers. J Colloid Interface Sci. 1980;77(2):353–62.

Panzer U, Schreiber HP. On the evaluation of surface interactions by inverse gas chromatography. Macromolecules. 1992;25(14):3633–7.

Volpe CD, Siboni S. Some reflections on acid–base solid surface free energy theories. J Colloid Interface Sci. 1997;195(1):121–36.

Clint JH, Dunstan TS. Acid–base components of solid surfaces and the triboelectric series. Europhys Lett. 2001;54(3):320.

Ho R, Heng JYY. A review of inverse gas chromatography and its development as a tool to characterize anisotropic surface properties of pharmaceutical solids. Kona Powder Part J. 2013;30:164–80.

Gamble JF, Chiu WS, Tobyn MJ. Investigation into the impact of sub-populations of agglomerates on the particle size distribution and flow properties of conventional microcrystalline cellulose grades. Pharm Dev Technol. 2011;16(5):542–8.

Wang D. Advanced physical characterisation of milled pharmaceutical solids, PhD Thesis. London: Imperial College London; 2013.

Head KH. Manual of soil laboratory testing. 2nd ed. New York: Pantech Press; 1994.

Guoxian L, Erde W, Zhongren W. Effects of ball-milling intensity on the amorphization rate of mixed Ni50Ti50 powders. J Mater Process Technol. 1995;51(1–4):122–30.

Mackin L, Zanon R, Park JM, Foster K, Opalenik H, Demonte M. Quantification of low levels (<10%) of amorphous content in micronised active batches using dynamic vapour sorption and isothermal microcalorimetry. Int J Pharm. 2002;231(2):227–36.

Hüttenrauch R, Fricke S, Zielke P. Mechanical activation of pharmaceutical systems. Pharm Res. 1985;2(6):302–6.

Ksiażek K, Wacke S, Górecki T, Cz G. Effect of the milling conditions on the degree of amorphization of selenium by milling in a planetary ball mill. J Phys Conf Ser. 2007;79(1):012037.

Crowley KJ, Zografi G. Cryogenic grinding of indomethacin polymorphs and solvates: assessment of amorphous phase formation and amorphous phase physical stability. J Pharm Sci. 2002;91(2):492–507.

Elamin AA, Sebhatu T, Ahlneck C. The use of amorphous model substances to study mechanically activated materials in the solid state. Int J Pharm. 1995;119(1):25–36.

Hurtta M, Pitkänen I. Quantification of low levels of amorphous content in maltitol. Thermochim Acta. 2004;419(1–2):19–29.

Mullin JW. Crystallization. Oxford: Elsevier Butterworth-Heinemann; 2001.

Zhang J, Ebbens S, Chen X, Jin Z, Luk S, Madden C, et al. Determination of the surface free energy of crystalline and amorphous lactose by atomic force microscopy adhesion measurement. Pharm Res. 2006;23(2):401–7.

Ward S, Perkins M, Zhang J, Roberts CJ, Madden CE, Luk SY, et al. Identifying and mapping surface amorphous domains. Pharm Res. 2005;22(7):1195–202.

Briggs D, Seah MP. Practical surface analysis by ager and X-ray photoelectron spectroscopy. 1st ed. New York: Wiley; 1983.

Beamson G, Briggs D. High resolution XPS of organic polymers, the scienta ESCA300 database. 1st ed. Chichester: Wiley; 1992.

SeethaLekshmi S, Guru Row TN. Conformational polymorphism in a non-steroidal anti-inflammatory drug, mefenamic acid. Cryst Growth Des. 2012;12(8):4283–9.

ACKNOWLEDGMENT AND DISCLOSURES

We would like to thank Mr. John Gamble for his help with particle size and shape analysis using Morphologi G3s.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shah, U.V., Olusanmi, D., Narang, A.S. et al. Decoupling the Contribution of Surface Energy and Surface Area on the Cohesion of Pharmaceutical Powders. Pharm Res 32, 248–259 (2015). https://doi.org/10.1007/s11095-014-1459-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11095-014-1459-3