ABSTRACT

Purpose

To present a new screening methodology intended to be used in the early development of spray-dried amorphous solid dispersions.

Methods

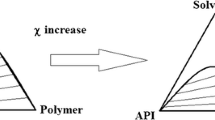

A model that combines thermodynamic, kinetic and manufacturing considerations was implemented to obtain estimates of the miscibility and phase behavior of different itraconazole-based solid dispersions. Additionally, a small-scale solvent casting protocol was developed to enable a fast assessment on the amorphous stability of the different drug-polymer systems. Then, solid dispersions at predefined drug loads were produced in a lab-scale spray dryer for powder characterization and comparison of the results generated by the model and solvent cast samples.

Results

The results obtained with the model enabled the ranking of the polymers from a miscibility standpoint. Such ranking was consistent with the experimental data obtained by solvent casting and spray drying. Moreover, the range of optimal drug load determined by the model was as well consistent with the experimental results.

Conclusions

The screening methodology presented in this work showed that a set of amorphous formulation candidates can be assessed in a computer model, enabling not only the determination of the most suitable polymers, but also of the optimal drug load range to be tested in laboratory experiments. The set of formulation candidates can then be further fine-tuned with solvent casting experiments using a small amount of API, which will then provide the decision for the final candidate formulations to be assessed in spray drying experiments.

Similar content being viewed by others

Abbreviations

- ASD(s):

-

Amorphous solid dispersion(s)

- SDD(s):

-

Spray dried dispersion(s)

- ITZ:

-

Itraconazole

- SC:

-

Solvent casting

- SD:

-

Spray drying

- HPMCAS-MG:

-

Hydroxypropyl methylcellulose acetate succinate (grade MG)

- PVP/VA 64:

-

Polyvinylpyrrolidone-vinyl acetate copolymer

- Eudragit® EPO:

-

Copolymer of dimethylaminoethyl methacrylate, butyl methacrylate and methyl methacrylate

- Tg :

-

Glass transition temperature

REFERENCES

Lipp R. The Innovator Pipeline: Bioavailability Challenges and Advanced Oral Drug Delivery Opportunities. American Pharmaceutical Review. 2013;16(3).

Thayer AM. Finding Solutions: Custom Manufacturers Take On Drug Solubility Issues To Help Pharmaceutical Firms Move Products Through Development. Chem Eng News. 2010;88(22):13–8.

Perrie Y, Rades T. Pharmaceutics - Drug Delivery and Targeting: Pharmaceutical Press; 2010.

Smithey D, Gao P, Taylor L. Amorphous solid dispersions: An enabling formulation technology for oral delivery of poorly water soluble drugs. AAPS Newsmagazine. 2013;16(1):11–4.

Newman A, Knipp G, Zografi G. Assessing the Performance of Amorphous Solid Dispersions. J Pharm Sci. 2012;101:1355–77.

[Online]. Accessed December 2013. Available from: http://www.pharma-iq.com/preclinical-discovery-and-development/articles/ensuring-stability-the-biggestamorphous-challenge/.

Janssens S, Van den Mooter G. Review: physical chemistry of solid dispersions. J Pharm Pharmacol. 2009;61:1571–86.

Van den Mooter G. The use of amorphous solid dispersions: A formulation strategy to overcome poor solubility and dissolution rate. Drug Discovery Today: Technologies. 2012;9(2):e79–85.

Marsac P, Shamblin S, Taylor LS. Theoretical and practical approaches for prediction of drug-polymer miscibility and solubility. Pharm Res. 2006;23(10):2417–26.

Tian Y, Booth J, Meehan E, Jones DS, Li S, Andrews P. Construction of Drug−Polymer Thermodynamic Phase Diagrams Using Flory−Huggins Interaction Theory: Identifying the Relevance of Temperature and Drug Weight Fraction to Phase Separation within Solid Dispersions. Mol Pharm. 2013;10:236–48.

Tian Y, Caron V, Jones DS, Healy AM, Andrews GP. Using Flory-Huggins phase diagrams as a pre-formulation tool for the production of amorphous solid dispersions: a comparison between hot-melt extrusion and spray drying. J Pharm Pharmacol. 2014;66(2):256–74.

Zhao Y, Inbar P, Chokshi HP, Malick AW, Choi DS. Prediction of the thermal phase diagram of amorphous solid dispersions by Flory-Huggins theory. J Pharm Sci. 2011;100(8):3196–207.

Paudel A, Nies E, Van den Mooter G. Relating hydrogen-bonding interactions with the phase behavior of naproxen/PVP K 25 solid dispersions: Evaluation of solution-casted and quench-cooled films. Mol Pharm. 2012;9(11):3301–17.

Bellantone RA, Patel P, Sandhu H, Choi DS, Singhal D, Chokshi H, et al. A Method to Predict the Equilibrium Solubility of Drugs in Solid Polymers near Room Temperature Using Thermal Analysis. J Pharm Sci. 2012;101(12):4549–58.

Kyeremateng SO, Pudlas M, Woehrle GH. A Fast and Reliable Empirical Approach for Estimating Solubility of Crystalline Drugs in Polymers for Hot-Melt Extrusion Formulations. Journal of Pharmaceutical Sciences. 2014.

Mahieu A, Willart JF, Dudognon E, Danède F, Descamps. A new protocol to determine the solubility of drugs into polymer matrixes. Mol Pharm. 2013;10(2).

Tao J, Sun Y, Zhang GGZ, Yu L. Solubility of Small-Molecule Crystals in Polymers: D-Mannitol in PVP, Indomethacin in PVP/VA, and Nifedipine in PVP/VA. Pharm Res. 2009;26(4).

Greenhalgh DJ, Willimans AC, Timmins P, York P. Solubility parameters as predictors of miscibility in solid dispersions. J Pharm Sci. 1999;88(11):1182–90.

Forster A, Hempenstall J, Tucker I, Rades. Selection of excipients for melt extrusion with two poorly water-soluble drugs by solubility parameter calculation and thermal analysis. Int J Pharm. 2001;226:147–61.

Marsac PJ, Rumondor AC, Nivens DE, Kestur US, Stanciu L, Taylor LS. Effect of Temperature and Moisture on the Miscibility of Amorphous Dispersions of Felodipine and Poly(vinyl pyrrolidone). J Pharm Sci. 2010;99(1):169–85.

Albers J, Matthée K, Knop K, Kleinebudde P. Evaluation of predictive models for stable solid solution formation. 2011;100(2):667–80.

Keen JM, Martin, Machado A, Sandhu, McGinity JW, DiNunzio JC. Investigation of process temperature and screw speed on properties of a pharmaceutical solid dispersion using corotating and counter-rotating twin-screw extruders. J Pharm Pharmacol. 2014;66(2):204–17.

Saylor DM, Kim CS, Patwardhan DV, Warren JA. Diffuse-interface theory for structure formation and release behavior in controlled drug release systems. Acta Biomater. 2007;3:851–64.

Saylor DM. Predicting Microstructure Evolution in Controlled Drug Release Coatings. In FDA/NHLBI/NSF Workshop on Computer Methods for Cardiovascular Devices ; 2010; USA.

Guyer JE, Wheeler D, Warren JA. FiPy:Partial Differential Equations with Python. Computing in Science & Engineering. 2009;11(3):6–15.

Krevlen DW. Nijenhuis Kt. Properties of Polymers Amsterdam: Elsevier; 2009.

Lin D, Huang Y. A thermal analysis method to predict the complete phase diagram of drug-polymer solid dispersions. Int J Pharm. 2010;399(1–2):109–15.

Kawakami K, Hasegawa Y, Deguchi K, Ohki S, Shimizu T, Yoshihashi Y, et al. Competition of Thermodynamic and Dynamic Factors During Formation of Multicomponent Particles via Spray Drying. J Pharm Sci. 2013;102(2):518–29.

Wilke CR, Chang P. Correlation of diffusion coeficients in dilute solutions. AIChE Journal. 1955;: p. 264-270.

Masters K. Spray Drying in Practice Denmark: SprayDry Consult. 2002.

Goula AM, Adamopoulos KG. Influence of Spray Drying Conditions on Residue Accumulation - Simulation Using CFD. Dry Technol. 2004;22(5):1107–28.

Poling BE, Prausnitz JM. O'Connell JP. The Properties of Gases and Liquids: McGraw-Hill; 2001.

Miller RS, Harstad K, Bellan J. Evaluation of equilibrium and non-equilibrium evaporation models for many-droplet gas-liquid flow simulations. Int J Multiphase Flow. 1998;24:1025–55.

Paudel A, Humbeeck JV, Van den Mooter G. Theoretical and Experimental Investigation on the Solid Solubility and Miscibility of Naproxen in Poly(vinylpyrrolidone). Mol Pharm. 2010;7(4):1133–48.

Baird JA, Taylor LS. Evaluation of amorphous solid dispersion properties using thermal analysis techniques. Adv Drug Deliv Rev. 2012;64(5):396–421.

Six K, Verreck G, Peeters, Binnemans, Berghmans, Augustijns, et al. Investigation of thermal properties of glassy itraconazole: identification of a monotropic mesophase. Thermochim Acta. 2001;376:175–81.

Fedors RF. A Method for Estimating Both the Solubility Parameters and Molar Volumes of liquids. Polym Eng Sci. 1974;14(2):147–54.

Barton AFM. Handbook of Solubility Parameters and Other Cohesion Parameters Florida: Boca Raton, CRC Press; 1983

Janssens S, de Armas N, Autry D, Van S, den Mooter V. Characterization of ternary solid dispersions of Itraconazole in polyethylene glycol 6000/polyvidone-vinylacetate 64 blends. Eur J Pharm Biopharm. 2008;69:1114–20.

Marsac PJ, Li T, Taylor LS. Estimation of drug polymer miscibility and solubility in amorphous solid dispersions using experimentally determined interaction parameters. Pharm Res. 2009;26(1):139–51.

Six K, Verreck G, Peeters J, Brewster M, Van den Mooter G. Increased Physical Stability and Improved Dissolution Properties of Itraconazole, a Class II Drug, by Solid Dispersions that Combine Fast- and Slow-Dissolving Polymers. J Pharm Sci. 2004;93(1):124–31.

Marsac PJ, Li T, Taylor LS. Estimation of drugpolymer miscibility and solubility in amorphous solid dispersions using experimentally determined interaction parameters. Pharm Res. 2009;26(1):139–51.

Overhoff, Moreno A, Miller DA, Johnston P, Williams III RO. Solid dispersions of itraconazole and enteric polymers made by ultra-rapid freezing. Int J Pharm. 2007;336:122–32.

Rumondor CF, Wikström H, Eerdenbrugh V, Taylor LS. Understanding the Tendency of Amorphous Solid Dispersions to Undergo Amorphous–Amorphous Phase Separation in the Presence of Absorbed Moisture. AAPS PharmSciTech. 2011;12(4):1209–19.

Janssens S, Nagels S, de Novoa HA, Van Schepdael A, Van den Mooter G. Formulation and characterization of ternary solid dispersions made up of Itraconazole and two excipients, TPGS 1000 and PVPVA 64, that were selected based on a supersaturation screening study. Eur J Pharm Biopharm. 2008;69:158–66.

Vasanthavada M, Tong WQ, Joshi, Kislalioglu. Phase Behavior of Amorphous Molecular Dispersions I: Determination of the Degree and Mechanism of Solid Solubility. Pharm Res. 2004;21(9):1598–606.

van Drooge DJ, Hinrichs WLJ, Visser MR, Frijlink HW. Characterization of the molecular distribution of drugs in glassy solid dispersions at the nano-meter scale, using differential scanning calorimetry and gravimetric water vapour sorption techniques. Int J Pharm. 2006;310:220–9.

Pharmaceutical Development. ICHQ8(R2). Geneva: International Conference on Harmonisation; 2009.

Janssens S, Zeure AD, Paudel A, Humbeeck JV, Rombaut P, Van den Mooter G. Influence of Preparation Methods on Solid State Supersaturation of Amorphous Solid Dispersions: A Case Study with Itraconazole and Eudragit E100. Pharm Res. 2010;27(5):775–85.

ACKNOWLEDGMENTS AND DISCLOSURES

Íris Duarte would like to thank the financial support from Hovione Farmaciência SA and from Fundação para a Ciência e Tecnologia through the doctoral grant BDE/51422/2011.

Author information

Authors and Affiliations

Corresponding author

Electronic Supplementary Material

Below is the link to the electronic supplementary material.

ESM 1

(5.99 mb)

Rights and permissions

About this article

Cite this article

Duarte, Í., Santos, J.L., Pinto, J.F. et al. Screening Methodologies for the Development of Spray-Dried Amorphous Solid Dispersions. Pharm Res 32, 222–237 (2015). https://doi.org/10.1007/s11095-014-1457-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11095-014-1457-5