ABSTRACT

Purpose

To construct a simple simulator reproducing human inspiratory flow patterns and use it to evaluate the inhalation performance of active ingredient particle-carrier particle systems (physically mixed dry powders).

Methods

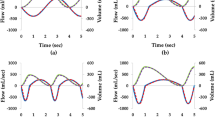

Inspiratory flow patterns were collected and analyzed using a flow recorder. The simulator was constructed using an airtight container, a valve, and a connecting tube. Several of the patterns reproduced by the simulator were compared with those recorded. In addition, the influence of inspiratory flow on the inhalation performance of physically mixed dry powders composed of salbutamol sulfate (SS) and coarse lactose monohydrate was investigated using a twin-stage liquid impinger (TSLI) equipped with the simulator.

Results

Human inspiratory flow patterns could be characterized by three parameters: inspiratory flow volume (area under the flow rate-time curve (AUC)), flow increase rate (FIR), and peak flow rate (PFR). The patterns could be reproduced using the simulator. Testing with the simulator in vitro revealed that PFR, but not FIR or AUC, greatly affected the inhalation performance of physically mixed dry powders.

Conclusions

The simulator is simple to construct and can schematically reproduce human inspiratory flow patterns. Testing with a TSLI and the simulator is useful to evaluate dry powder formulations for clinical application.

Similar content being viewed by others

REFERENCES

Adi H, Young PM, Chan HK, Stewart P, Agus H, Traini D. Cospray dried antibiotics for dry powder lung delivery. J Pharm Sci. 2008;97(8):3356–66.

Dalby R, Suman J. Inhalation therapy: technological milestones in asthma treatment. Adv Drug Deliv Rev. 2003;55(7):779–91.

Edwards DA, Hanes J, Caponetti G, Hrkach J, Ben-Jebria A, Eskew ML, et al. Large porous particles for pulmonary drug delivery. Science. 1997;276(5320):1868–71.

Patton JS, Byron PR. Inhaling medicines: delivering drugs to the body through the lungs. Nat Rev Drug Discov. 2007;6(1):67–74.

Guenette E, Barrett A, Kraus D, Brody R, Harding L, Magee G. Understanding the effect of lactose particle size on the properties of DPI formulations using experimental design. Int J Pharm. 2009;380(1–2):80–8.

Mizuno T, Mohri K, Nasu S, Danjo K, Okamoto H. Dual imaging of pulmonary delivery and gene expression of dry powder inhalant by fluorescence and bioluminescence. J Control Release. 2009;134(2):149–54.

Bouchard A, Jovanović N, Hofland GW, Jiskoot W, Mendes E, Crommelin DJ, et al. Supercritical fluid drying of carbohydrates: selection of suitable excipients and process conditions. Eur J Pharm Biopharm. 2008;68(3):781–94.

Mohri K, Okuda T, Mori A, Danjo K, Okamoto H. Optimized pulmonary gene transfection in mice by spray-freeze dried powder inhalation. J Control Release. 2010;144(2):221–6.

Tomoda K, Ohkoshi T, Hirota K, Sonavane GS, Nakajima T, Terada H, et al. Preparation and properties of inhalable nanocomposite particles for treatment of lung cancer. Colloids Surf B Biointerfaces. 2009;71(2):177–82.

Op’t Holt TB. Inhaled beta agonists. Respir Care. 2007;52(7):820–32.

Okamoto H, Danjo K. Application of supercritical fluid to preparation of powders of high-molecular weight drugs for inhalation. Adv Drug Deliv Rev. 2008;60(3):433–46.

Taki M, Marriott C, Zeng XM, Martin GP. Aerodynamic deposition of combination dry powder inhaler formulations in vitro: a comparison of three impactors. Int J Pharm. 2010;388(1–2):40–51.

Telko MJ, Hickey AJ. Dry powder inhaler formulation. Respir Care. 2005;50(9):1209–27.

Young PM, Kwok P, Adi H, Chan HK, Traini D. Lactose composite carriers for respiratory delivery. Pharm Res. 2009;26(4):802–10.

Saleem I, Smyth H, Telko M. Prediction of dry powder inhaler formulation performance from surface energetics and blending dynamics. Drug Dev Ind Pharm. 2008;34(9):1002–10.

Mitchell J, Dalby R. Characterization of aerosol performance. In: Bechtold-Peters K, Lüssen H, editors. Pulmonary drug delivery—basics, applications and opportunities for small molecules and bio-pharmaceuticals, Chapter 5. Aulendorf: Editio Cantor Verlag; 2006. p. 282–305.

Section 2.9.18-Preparation for inhalation: aerodynamic assessment of fine particles. European Pharmacopoeia. 1997.

Hoe S, Traini D, Chan HK, Young PM. Measuring charge and mass distributions in dry powder inhalers using the electrical Next Generation Impactor (eNGI). Eur J Pharm Sci. 2009;38(2):88–94.

Lee SL, Adams WP, Li BV, Conner DP, Chowdhury BA, Yu LX. In vitro considerations to support bioequivalence of locally acting drugs in dry powder inhalers for lung diseases. AAPS J. 2009;11(3):414–23.

Martin GP, Marriott C, Zeng XM. Influence of realistic inspiratory flow patterns on fine particle fractions of dry powder aerosol formulations. Pharm Res. 2007;24(2):361–9.

Lohrmann M, Kappl M, Butt HJ, Urbanetz NA, Lippold BC. Adhesion forces in interactive mixtures for dry powder inhalers—evaluation of a new measuring method. Eur J Pharm Biopharm. 2007;67(2):579–86.

Chavan V, Dalby R. Novel system to investigate the effects of inhaled volume and rates of rise in simulated inspiratory air flow on fine particle output from a dry powder inhaler. AAPS PharmSci. 2002;4(2):E6.

Finlay WH, Gehmlich MG. Inertial sizing of aerosol inhaled from two dry powder inhalers with realistic breath patterns versus constant flow rates. Int J Pharm. 2000;210(1–2):83–95.

Zanen P, van Spiegel PI, van der Kolk H, Tushuizen E, Enthoven R. The effect of the inhalation flow on the performance of a dry powder inhalation system. Int J Pharm. 1992;81(2–3):199–203.

Mitchell J, Newman S, Chan HK. In vitro and in vivo aspects of cascade impactor tests and inhaler performance: a review. AAPS PharmSciTech. 2007;8(4):E110.

Huang WH, Yang ZJ, Wu H, Wong YF, Zhao ZZ, Liu L. Development of liposomal salbutamol sulfate dry powder inhaler formulation. Biol Pharm Bull. 2010;33(3):512–7.

Iida K, Inagaki Y, Todo H, Okamoto H, Danjo K, Luenberger H. Effects of surface processing of lactose carrier particles on dry powder inhalation properties of salbutamol sulfate. Chem Pharm Bull (Tokyo). 2004;52(8):938–42.

Chavan V, Dalby R. Effect of rise in simulated inspiratory flow rate and carrier particle size on powder emptying from dry powder inhalers. AAPS PharmSci. 2000;2(2):E10.

Kumon M, Machida S, Suzuki M, Kusai A, Yonemochi E, Terada K. Application and mechanism of inhalation pattern improvement of DPI formulations by mechanofusion with magnesium stearate. Chem Pharm Bull (Tokyo). 2008;56(5):617–25.

Zijlstra GS, Hinrichs WL, de Boer AH, Frijlink HW. The role of particle engineering in relation to formulation and de-agglomeration principle in the development of a dry powder formulation for inhalation of cetrorelix. Eur J Pharm Sci. 2004;23(2):139–49.

Zanen P, Laube BL. Targeting the lungs with therapeutic aerosols. In: Bisgaard H, Callaghan CO, Smaldone GC, editors. Drug delivery to the lung, Chapter 7, vol. 162. 2002. p. 211–68.

de Boer AH, Winter HMI, Lerk CF. Inhalation characteristics and their effects on in vitro drug delivery from dry powder inhalers Part 1. Inhalation characteristics, work of breathing and volunteers’ preference in dependence of the inhaler resistance. Int J Pharm. 1996;130(2):231–44.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hira, D., Okuda, T., Kito, D. et al. Inhalation Performance of Physically Mixed Dry Powders Evaluated with a Simple Simulator for Human Inspiratory Flow Patterns. Pharm Res 27, 2131–2140 (2010). https://doi.org/10.1007/s11095-010-0215-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11095-010-0215-6