Abstract

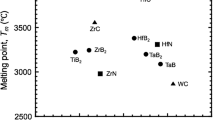

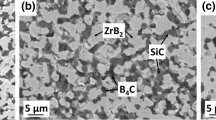

Oxidation behavior of additively manufactured ZrB2–SiC in air and in CO2 is reported in the temperature range of 700–1000 °C. Observed scale morphologies in air and in CO2 were similar, featuring an outer borosilicate layer and an inner porous zirconia layer containing partially oxidized silicon carbide particles and remnant borosilicate products. Oxide scale thicknesses and parabolic scaling constants in air were approximately twice those observed in CO2 across all studied temperatures. Activation energies for oxidation of 140 ± 20 kJ/mol in air and 110 ± 20 kJ/mol in CO2 were determined, indicating similar diffusion processes that appear to be rate-limiting. The formation of protective scales across wide temperature ranges both in air and in CO2 makes additively manufactured ZrB2–SiC an attractive candidate for high-temperature industrial process applications featuring varied oxidants such as heat exchangers.

Similar content being viewed by others

References

W. G. Fahrenholtz and G. E. Hilmas, Scr Mater 129, 2017 (94). https://doi.org/10.1016/j.scriptamat.2016.10.018.

A. Paul, J. Binner and B. Vaidhyanathan, in Ultra-High Temperature Ceramics: Materials for Extreme Environment Applications, eds. W. G. Fahrenholtz, E. J. Wuchina, W. E. Lee and Y. Zhou, (Wiley, Hoboken, 2014), p. 144.

D. Alfano, R. Gardi, L. Scatteia and A. Del Vecchio, in. Ultra-High Temperature Ceramics: Materials for Extreme Environment Applications, eds. W. G. Fahrenholtz, E. J. Wuchina, W. E. Lee and Y. Zhou, (Hoboken, Wiley,2014), p. 416.

T. G. Aguirre, B. W. Lamm, C. L. Cramer, and D. J. Mitchell, Ceram Int 48, 2022 (7344). https://doi.org/10.1016/j.ceramint.2021.11.314.

A. H. Rafi, M. Lakusta, V. Anthony, et al., in 2022 International Solid Freeform Fabrication Symposium – An Additive Manufacturing Conference. https://doi.org/10.26153/tsw/44137.

B. A. Pint and J. R. Keiser, Oxidation of Metals 98, 2022 (545). https://doi.org/10.1007/s11085-022-10134-2.

K. Li, Z. Zhu, B. Xiao, J. L. Luo, and N. Zhang, Progress in Materials Science 136, 2023 101107. https://doi.org/10.1016/j.pmatsci.2023.101107.

Y. Ahn, S. J. Bae, M. Kim, et al., Nuclear Engineering and Technology 47, 2015 (647). https://doi.org/10.1016/j.net.2015.06.009.

S. D. Maher, M. Sarvghad, R. Olivares, T. C. Ong, G. Will, and A. Steinberg, Solar Energy Materials and Solar Cells 242, 2022 111768. https://doi.org/10.1016/j.solmat.2022.111768.

K. A. Kane, B. A. Pint, D. Mitchell, and J. A. Haynes, Journal of the European Ceramic Society 41, 2021 (6130). https://doi.org/10.1016/j.jeurceramsoc.2021.05.055.

R. Inoue, Y. Arai, Y. Kubota, Y. Kogo, and K. Goto, Journal of Materials Science 53, 2018 (14885). https://doi.org/10.1007/s10853-018-2601-0.

W. G. Fahrenholtz and G. E. Hilmas, International Materials Reviews 57, 2012 (61). https://doi.org/10.1179/1743280411Y.0000000012.

A. Rezaie, W. G. Fahrenholtz, and G. E. Hilmas, Journal of the European Ceramic Society 27, 2007 (2495). https://doi.org/10.1016/j.jeurceramsoc.2006.10.012.

W. C. Tripp, H. H. Davis, and H. C. Graham, American Ceramic Society Bulletin 52, 1973 (26).

W. C. Tripp and H. C. Graham, Journal of the Electrochemical Society 118, 1971 (1195). https://doi.org/10.1149/1.2408279.

H. C. Graham, H. H. Davis, I. A. Kvernes and W. C. Tripp, in Ceramics in Severe Environments. Materials Science Research, vol. 5, eds. W. W. Kriegel, H. (Springer, Palmour Boston) p. 35. https://doi.org/10.1007/978-1-4684-3141-4_4.

S. N. Karlsdottir and J. W. Halloran, Journal of the American Ceramic Society 92, 2009 (481). https://doi.org/10.1111/j.1551-2916.2008.02874.x.

P. A. Williams, R. Sakidja, J. H. Perepezko, and P. Ritt, Journal of the European Ceramic Society 32, 2012 (3875). https://doi.org/10.1016/j.jeurceramsoc.2012.05.021.

J. W. Zimmermann, G. E. Hilmas, W. G. Fahrenholtz, R. B. Dinwiddie, W. D. Porter, and H. Wang, Thermophysical properties of ZrB2 and ZrB2–SiC ceramics. Journal of the American Ceramic Society. 91, (5), 2008 (1405–1411). https://doi.org/10.1111/j.1551-2916.2008.02268.x.

A. L. Chamberlain, W. G. Fahrenholtz, G. E. Hilmas, and D. T. Ellerby, Journal of the American Ceramic Society 87, 2004 (1170). https://doi.org/10.1111/j.1551-2916.2004.01170.x.

E. W. Neuman, G. E. Hilmas, and W. G. Fahrenholtz, Journal of the European Ceramic Society 33, 2013 (2889). https://doi.org/10.1016/j.jeurceramsoc.2013.05.003.

S. C. Zhang, G. E. Hilmas and W. G. Journal of the European Ceramic Society 31, 893 (2011). https://doi.org/10.1016/j.jeurceramsoc.2010.11.013

E. J. Opila and Q. N. Nguyen Journal of the American Ceramic Society 81, 1949 (1998). https://doi.org/10.1111/j.1151-2916.1998.tb02573.x.

B. S. Walker, W. York, J. Chames, et al. Sandia Report SAND2019–3379, Accessed September 01, 2023 (2019).

K. Sridharan, DE-NE0000677 Final Report (NEUP Ref: 13–4900), Accessed September 01, 2023 (2017).

A. Ghazanfari, W. Li, M. C. Leu, and G. E. Hilmas, Additive Manufacturing 15, 2017 (102). https://doi.org/10.1016/j.addma.2017.04.001.

C. W. Bale, E. Bélisle, P. Chartrand, et al., Calphad 54, 2016 (35). https://doi.org/10.1016/j.calphad.2016.05.002.

I. Barin, in Thermochemical Data of Pure Substances (Weinheim: VCH Verlagsgesellschaft mbH, 1995).

T. D. Nguyen, G. D. Scofield, S. Hwang, et al., Journal of Materials Research and Technology 15, 2021 (4852). https://doi.org/10.1016/j.jmrt.2021.10.098.

H. Yokokawa, T. Kawada, and M. Dokiya, Journal of the American Ceramic Society 72, 1989 (2104). https://doi.org/10.1111/j.1151-2916.1989.tb06039.x.

C. R. Wang, J. M. Yang and W. Hoffman Materials chemistry and physics 74, 272 (2002). https://doi.org/10.1016/S0254-0584(01)00486-2.

C. Veytizou, J. F. Quinson, O. Valfort, and G. Thomas, Zircon formation from amorphous silica and tetragonal zirconia: kinetic study and modeling. Solid State Ionics 139, 2001 (315). https://doi.org/10.1016/S0167-2738(01)00676-2.

K. Song, J. Fan, W. Li, J. Jiang, Z. Xu, and C. Zhang, Effect of ZrO2 types on ZrSiO4 formation. Ceramics International 45, (17), 2019 (23444–23450).

A. K. Yadav, V. Ponnilavan, and S. J. Kannan, Ceramics International 16, 2016 (5493). https://doi.org/10.1016/j.ceramint.2019.08.048.

W. G. Fahrenholtz, Journal of the American Ceramic Society 90, 2007 (143). https://doi.org/10.1111/j.1551-2916.2006.01329.x.

F. Monteverdez and A. Bellosi, Journal of the Electrochemical Society 150, 2003 (552). https://doi.org/10.1149/1.1618226.

L. Zhang and K. Kurokawa, Oxidation of Metals 85, 2015 (33). https://doi.org/10.1007/s11085-015-9585-9.

S. Guo, Journal of Asian Ceramic Societies 8, 2020 (1239). https://doi.org/10.1080/21870764.2020.1840701.

M. G. Kakroudi, M. D. Alvari, M. S. Asl, N. P. Vafa, and T. Rabizadeh, Ceramics International 46, 2020 (3725). https://doi.org/10.1016/j.ceramint.2019.10.093.

R. J. Irving and I. G. Worsley, Journal of the Less Common Metals 16, 1968 (102). https://doi.org/10.1016/0022-5088(68)90067-2.

A. K. Kuriakose and J. L. Margrave, Journal of the Electrochemical Society 111, 2017 (827). https://doi.org/10.1149/1.2426263.

Acknowledgements

The authors express sincere gratitude to Dr. Eric Bohannan for his invaluable assistance with XRD and GD-OES analyses.

Funding

The information, data, or work presented herein was funded in part by the Advanced Research Projects Agency-Energy (ARPA-E), US Department of Energy, under Award Number DE-AR0001125.

Author information

Authors and Affiliations

Contributions

Credit Author Contribution Statement Marharyta Lakusta: Conceptualization, Methodology, Formal Analysis, Investigation, Visualization, Writing – Original Draft, Writing – Review & Editing. Nicholas M. Timme: Methodology, Writing – Review & Editing. Abid H. Rafi: Methodology, Writing – Review & Editing. Jeremy L. Watts: Methodology, Supervision, Writing – Review & Editing. Ming Leu: Supervision, Writing – Review & Editing. Gregory E. Hilmas: Supervision, Writing – Review & Editing. William G. Fahrenholtz: Formal Analysis, Supervision, Writing – Review & Editing. David W. Lipke: Conceptualization, Formal Analysis, Writing-Reviewing and Editing, Resources, Supervision, Project Administration, Funding Acquisition.

Corresponding author

Ethics declarations

Conflict of interest

Authors Hilmas GE and Leu MC disclose patent US20170297221A1 whose method was used to produce articles tested in this manuscript (issued to University of Missouri System, inventors Leu MC, Ghazanfari A, Li W, Hilmas GE, Landers RG).

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Lakusta, M., Timme, N.M., Rafi, A.H. et al. Oxidation of Additively Manufactured ZrB2–SiC in Air and in CO2 at 700–1000 °C. High Temperature Corrosion of mater. (2024). https://doi.org/10.1007/s11085-024-10241-2

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11085-024-10241-2