Abstract

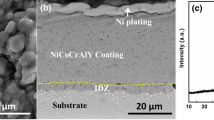

In the present investigation, a NiCr–Cr3C2 powder mixture was deposited on titanium aluminide substrate by laser cladding. The kinetics and mechanism of oxidation of the substrate and coating were studied at 800–1100 °C using XRD, SEM, ToF–SIMS and XPS characterization techniques. The results demonstrated that the Ni–Cr–C coating had improved oxidation resistance, as compared to the substrate. The oxidized surface of the coating was covered with Cr2O3 and NiCr2O4 phases at the early stages of the oxidation. The formation of NiCr2O4 could be attributed to the reaction of NiO (an oxidation product of the NiCr phase) and Cr2O3 (an oxidation product of the chromium carbide phase) during oxidation. Increasing the oxidation time at 900 °C led to the partial formation of CrO3 as a result of the oxidation of Cr2O3. It was also found that the parabolic rate constant ratio of \(\left( {K_{{\text{p}}}^{{{\text{substrate}}}} /K_{{\text{p}}}^{{{\text{coating}}}} } \right)\) increased with the temperature, which showed, comparatively, the better oxidation resistance of the coating at higher temperatures.

Similar content being viewed by others

References

K. Kothari, R. Radhakrishnan, and N. M. Wereley, Progress in Aerospace Sciences 55, 2012 (1–16).

F. H. Froes, C. Suryanarayana, and D. Eliezer, Journal of Materials Science 27, 1992 (5113–5140).

Y. Umakoshi, M. Yamaguchi, T. Sakagami, and T. Yamane, Journal of Materials Science 24, 1989 (1599–1603).

M. Barekat, R. ShojaRazavi, and A. Ghasemi, Optics & Laser Technology 80, 2016 (145–152).

Ch. Li, M. Zeng, Ch. Liu, F. Wang, Y. Guo, J. Wang, Y. Yang, W. Li, and Y. Wang, Materials Chemistry and Physics 240, 2020 (122271).

J. Becker, S. Schmigalla, S. Schultze, S.-K. Rittinghaus, A. Weisheit, J. Schmelzer, and M. Kruger, Oxidation of Metals 97, 2022 (167–181).

H. Wang, D. Zuo, J. Yan, M. Huang, and X. Li, Oxidation of Metals 74, 2010 (49–60).

E. Toyserkani, A. Khajepour, and S. F. Corbin, Laser Cladding, (CRC Press, Boca Raton, 2004).

Q. Meng, L. Geng, and D. Ni, Materials Letters 59, (22), 2005 (2774–2777).

S. E. Aghili, M. H. Enayati, and F. Karimzadeh, Acta Metallurgica Sinica (English Letters) 29, 2016 (911–919).

E. Qin, B. Wang, W. Li, W. Ma, H. Lu, and Sh. Wu, Journal of Thermal Spray Technology 28, 2019 (1072–1080).

K. Kaur, H. Singh, and S. Prakash, Surface and Coatings Technology 206, 2011 (530–541).

E. Gariboldi, L. Rovatti, N. Lecis, L. Mondora, and G. A. Mondora, Surface and Coatings Technology 305, 2016 (83–92).

N. Kaur, M. Kumar, S. K. Sharma, D. Y. Kim, S. Kumar, N. M. Chavan, S. V. Joshi, N. Singh, and H. Singh, Applied Surface Science 328, 2015 (13–25).

N. Bala, H. Singh, and S. Prakash, Metallurgical and Materials Transactions A 42, 2011 (3399–3416).

E. Schmucker, C. Petitjean, L. Martinelli, P. J. Panteix, B. Lagha, and M. Vilasi, Corrosion Science 111, 2016 (467–473).

S. Wu, B. Guo, T. Li, and D. Gu, Construction and Building Materials 81, 2015 (11–14).

S. Kumar, D. Mudgal, S. Singh, and S. Prakash, Advanced Materials Letters 4, (10), 2013 (754–761).

S. Matthews, B. James, and M. Hyland, Corrosion Science 51, 2009 (1172–1180).

S. E. Aghili and M. Shamanian, Optics & Laser Technology 119, 2019 (105652).

Y. W. Kim, Acta metallurgica et materialia 40, 1991 (1121–1133).

V. Sreenivasulu and M. Manikandan, Surface and Coatings Technology 337, 2018 (250–259).

G. Bolelli, L.-M. Berger, T. Börner, H. Koivuluoto, V. Matikainen, L. Lusvarghi, C. Lyphout, N. Markocsan, P. Nylén, P. Sassatelli, R. Trache, and P. Vuoristo, Wear 358–359, 2016 (32–50).

Ch. Pan, H. Wang, H. Wang, Q. Chang, and H. Wang, Journal Wuhan University of Technology, Materials Science Edition 25, 2010 (991–995).

G. Calvarin, R. Molins, and A. M. Huntz, Oxidation of Metals 53, 2000 (25–48).

Y. Ding, T. Hossein, and D. G. McCartney, Journal of Materials Science 50, 2015 (6808–6821).

F. X. Ye, S. H. Wu, and A. Ohmori, Journal of Thermal Spray Technology 17, 2008 (942–947).

D. J. Young, High Temperature Oxidation and Corrosion of Metals, 2nd ed (Elsevier, New York, 2016),.

T. Takahashi, Y. Minamino, H. Hirasawa, and T. Ouchi, Materials Transactions 55, (2), 2014 (290–297).

R. G. Reddy, X. Wen, and M. Divakar, Metallurgical and Materials Transactions A 32, 2000 (2357–2362).

J. Małecka, Advances in Materials Science 18, (2), 2018 (5–14).

P. Ouyang, G. Mi, P. Li, L. He, J. Cao, and X. Huang, Materials 12, (13), 2019 (2114).

X. Wu, S. Voyshnis, A. Seyeux, Y. Chumlyakov, and Ph. Marcus, Corrosion Science 141, 2018 (175–181).

S. E. Aghili, M. Shamanian, R. AminiNajafabadi, A. Keshavarzkermani, R. Esmaeilizadeh, U. Ali, E. Marzbanrad, and E. Toyserkani, Ceramics International 46, 2020 (1668–1679).

P. Berthod, Oxidation of Metals 64, (3–4), 2005 (235–252).

S. C. Tsai, A. M. Huntz, and C. Dolin, Materials Science and Engineering A 212, 1996 (6–13).

K. P. Lillerud and P. Kofstad, Journal of the Electrochemical Society 127, 1980 (2397–2410).

P. Kofstad and K. P. Lillerud, Journal of the Electrochemical Society 127, 1980 (2410–2419).

Acknowledgements

The authors would like to thank Biointerfaces Institute at McMaster University for conducting the XPS measurements. The authors also gratefully thank WATLAB, at the University of Waterloo, for conducting the SIMS experiments. In addition, we appreciate the members of Multi-Scale Additive Manufacturing (MSAM) group, especially Prof. Mihaela Vlasea, Dr. Ali Keshavarzkermani and Dr. Reza Esmaeilizadeh, for all their supports.

Funding

No funding was received to assist with the preparation of this paper.

Author information

Authors and Affiliations

Contributions

SEA was contributed to conceptualization, data curation, investigation, methodology, formal analysis, writing—original draft. MS was contributed to conceptualization, methodology, formal analysis, writing—review and editing, supervision. RAN was contributed to investigation, writing—review and editing. HA was contributed to investigation, writing—review and editing. EM was contributed to formal analysis, investigation, writing—review and editing. YM was contributed to writing—review and editing. ET was contributed to conceptualization, methodology, formal analysis, writing—review and editing, supervision.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Aghili, S.E., Shamanian, M., Amini Najafabadi, R. et al. Evaluation of Short-Term Oxidation Mechanism of Laser Cladded Ni–Cr–C Coating on Titanium Aluminide Substrate. High Temperature Corrosion of mater. 99, 311–329 (2023). https://doi.org/10.1007/s11085-023-10154-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11085-023-10154-6