Abstract

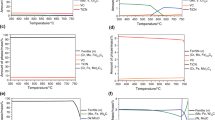

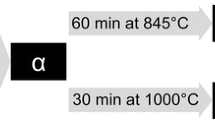

The high-temperature oxidation behavior of tool steel with increased thermal conductivity was studied in two conditions, the soft annealed condition, and the quenched and tempered condition. First, calculations of the composition of the oxide layers formed were predicted using the CALPHAD method. Then, one group of samples was oxidized in a chamber furnace and another group was oxidized in an instrument for simultaneous thermal analysis (STA) for 100 h in the temperature range between 400 and 700 °C. The first samples were used for microscopic analysis of the oxide layers, and the second for the study of oxidation kinetics. Equations describing the high-temperature oxidation kinetics were derived. The kinetics can be described by three mathematical functions: exponential, parabolic and cubic, depending on the oxidation temperature and the heat treatment of the steel. It has been shown that quenched and tempered samples oxidize less (thinner oxide layer), resulting in a slower oxidation rate. The oxide layers formed consisted of three sublayers, the inner one is a magnetite (Fe, Mo, Ni)3O4, the middle one is a mixture of magnetite and hematite, and the outer one is hematite. At 600 and 700 °C, wüstite is also present in the middle and inner oxide sublayers. The higher temperatures resulted in thicker oxide layers. A difference in the oxidation of the steel matrix and carbides was observed, as some carbides remained in the oxide layer. Internal oxidation was also observed at 600 and 700 °C.

Graphic abstract

Similar content being viewed by others

References

G. Roberts, G. Krauss, and R. Kennedy, Tool Steels, 5th ed (ASM International, Materials Park, 1998),.

R. A. Mesquita, Tool steels: properties and performance, (CRC Press, Boca Raton, FL, 2016).

J. Szumera, The tool steel guide, (Industrial Press, New York, 2003).

G. Krauss, Steels: processing, structure, and performance, (ASM International, Materials Park, 2015).

Z. Taha, A. R. Yusoff, M. F. Mohamd Sharif, M. A. H. Saharudin, and M. F. Zamri, Comparison of cooling performance between high thermal conductivity steel (HTCS 150) and hot work tool steel (SKD 61) insert for experimental tool using finite element analysis. Advanced on Materials and Research 903, 2014 (163–168).

M. Ayabe, T. Nagaoka, K. Shibata, et al., Effect of high thermal conductivity die steel in aluminum casting. International Journal of Metallic 2, 2008 (47–55).

S. Li, X. Wu, X. Li, and X. He, High temperature performance of a Mo-W type hotwork die steel of high thermal conductivity. Chinese Journal of Material and Research 31, 2017 (32–40).

E. Kaschnitz, P. Hofer, and W. Funk, Thermophysical properties of a hot-work tool-steel with high thermal conductivity. International Journal of Thermophysics 34, 2013 (843–850).

I. Valls, A. Hamasaiid, and A. Padré, High thermal conductivity and high wear resistance tool steels for cost-effective hot stamping tools. Journal of Physics Conference on Series 2017, 2017 (896).

Q. Zhou, X. Wu, N. Shi, J. Li, and N. Min, Microstructure evolution and kinetic analysis of DM hot-work die steels during tempering. Materials Science on Engineering A 528, 2011 (5696–5700).

A. Medvedeva, J. Bergström, S. Gunnarsson, and J. Andersson, High-temperature properties and microstructural stability of hot-work tool steels. Materials on Science and Engineering A 523, 2009 (39–46).

Z. Zhang, D. Delagnes, and G. Bernhart, Microstructure evolution of hot-work tool steels during tempering and definition of a kinetic law based on hardness measurements. Materials on Science and Engineering A. 380, 2004 (222–230).

N. Mebarki, D. Delagnes, P. Lamesle, F. Delmas, and C. Levaillant, Relationship between microstructure and mechanical properties of a 5% Cr tempered martensitic tool steel. Materials on Science and Engineering A. 387–389, 2004 (171–175).

A. Jilg and T. Seifert, Temperature dependent cyclic mechanical properties of a hot work steel after time and temperature dependent softening. Materials on Science and Engineering A. 721, 2018 (96–102).

D. Caliskanoglu, I. Siller, R. Ebner, H. Leitner, F. Jeglitsch, W. Waldhauser. Thermal fatigue and softening behavior of hot work tool steels. Proceedings of the 6th International Tools and Conference, 707–719, 2002

R. Markežič, N. Mole, I. Naglič, and R. Šturm, Time and temperature dependent softening of H11 hot-work tool steel and definition of an anisothermal tempering kinetic model. Materials on Today Communication 2020, 2020 (22).

G. Y. Lai, High-temperature corrosion and materials applications, (ASM International, Materials Park, 2007).

R. W. Revie, Uhlig’s corrosion handbook, (Wiley, Hoboken, NJ, 2011).

T. J. A. Richardson, B. Cottis, R. Lindsay, et al., Shreir’s Corrosion, vol. 1. (Elsevier Science, Amsterdam, London, 2009),.

D. J. Young, High temperature oxidation and corrosion of metals, (Elsevier, Amsterdam, Boston, London, 2016).

B. N. Popov, Corrosion engineering: principles and solved problems. Corrosion engineering: principles and solved problems, (Elsevier, Amsterdam, London, 2015).

P. Pedeferri, Corrosion science and engineering, (Springer, Cham, 2018).

Cramer SD, Covino BS. ASM handbook volume 13B: corrosion: materials. Materials Park: ASM International; 2005.

K. Hauffe, Oxidation of metals, (Springer, New York, 1965).

R. Y. Chen and W. Y. D. Yeun, Review of the high-temperature oxidation of iron and carbon steels in air or oxygen. Oxidation on Metal 59, 2003 (433–468).

N. Birks, G. H. Meier, and F. S. Pettit, Introduction to the high temperature oxidation of metals, (Cambridge University Press, Cambridge, 2006).

M. H. Davies, M. T. Simnad, and C. E. Birchenall, On the mechanism and kinetics of the scaling of iron. JOM. 3, 1951 (889–896).

N. B. Pilling and R. E. Bedworth, Oxidation of metals at high temperatures. Journal of Institutional Metallic 29, 1923 (529–539).

W. E. Boggs and R. H. Kachik, The oxidation of iron-carbon alloys at 500 °C. Journal of Electrochemical Society 116, 1969 (424–430).

D. Caplan and M. Cohen, Effect of cold work on the oxidation of iron from 400–650 °C. Corrosions on Science 6, 1966 (327–335).

D. Caplan, G. I. Sproule, and R. J. Hussey, Comparison of the kinetics ofhigh-temperature oxidation of Fe as influenced by metal purity and cold work. Corrosions on Science 10, 1970 (9–17).

S. Ghosh, M. K. Kumar, and V. Kain, High temperature oxidation behavior of AISI 304L stainless steel: effect of surface working operations. Applied Surface on Science 264, 2013 (312–319).

H. Abuluwefa, R. I. L. Guthrie, and F. Ajersch, The effect of oxygen concentration on the oxidation of low-carbon steel in the temperature range 1000 to 1250 °C. Oxidation on Metallic 46, 1996 (423–440).

D. Li, Q. Dai, X. Cheng, R. Wang, and Y. Huang, High-temperature oxidation resistance of austenitic stainless steel Cr18Ni11Cu3Al3MnNb. Journal of Ironic Steel Research on International 19, 2012 (74–78).

R. Y. Chen and W. Y. Yuen, Oxidation of low-carbon, low-silicon mild steel at 450–900 °C under conditions relevant to hot-strip processing. Oxidation on Metallic 57, 2002 (53–79).

M. Hao, B. Sun, and H. Wang, High-temperature oxidation behavior of Fe–1Cr–0.2Si steel. Materials (Basel) 13, 2020 (1–18).

D. Caplan, G. I. Sproule, R. J. Hussey, and M. J. Graham, Oxidation of Fe-C alloys at 500 °C. Oxidation on Metallics 12, 1978 (67–82).

D. Caplan, G. I. Sproule, R. J. Hussey, and M. J. Graham, Oxidation of Fe-C alloys at 700 °C. Oxidation on Metallics 13, 1979 (255–272).

S.-H. Bak, M.-J. Kim, J.-H. Lee, S.-J. Bong, S.-K. Kim, and D.-B. Lee, High-temperature oxidation kinetics and scales formed on Fe–2.3%Cr–1.6%W alloy. Journal of Korean Ceramic Society 48, 2011 (57–62).

G. Cao, X. Liu, B. Sun, and Z. Liu, Morphology of oxide scale and oxidation kinetics of low carbon steel. Journal of the Iron Steel Research on International 21, 2014 (335–341).

A. U. Malik and D. P. Whittle, Oxidation of Fe-C alloys in the temperature range 600–850 °C. Oxidation on Metallic 16, 1981 (339–353).

M. H. S. Bidabadi, S. Chandra-ambhorn, A. Rehman, et al., Carbon depositions within the oxide scale and its effect on the oxidation behavior of low alloy steel in low (0.1 MPa), sub-(5 MPa) and supercritical (10 MPa) CO2 at 550 °C. Corrosions on Science 177, 2020 (108950).

Y. Min, X. Wu, K. Wang, L. Li, and L. Xu, Prediction and analysis on oxidation of H13 hot work steel. Journal of the Iron Steel Research on International 13, 2006 (44–49).

X. Zhang, X. Jie, L. Zhang, S. Lui, and Q. Zheng, Improving the high-temperature oxidation resistance of H13 steel by laser cladding with a WC/Co–Cr alloy coating. Anti-Corrosion Methods Materials 63, 2016 (171–176).

S. R. J. Saunders, M. Monteiro, and F. Rizzo, The oxidation behaviour of metals and alloys at high temperatures in atmospheres containing water vapour: a review. Progessive on Materials Science 53, 2008 (775–837).

J. Zurek, E. Wessel, L. Niewolak, et al., Anomalous temperature dependence of oxidation kinetics during steam oxidation of ferritic steels in the temperature range 550–650 °C. Corrosions on Science 46, 2004 (2301–2317).

T. Balaško, M. Vončina, J. Burja, B. Š Batič, and J. Medved, High-temperature oxidation behaviour of aisi h11 tool steel. Metals (Basel) 2021, 2021 (11).

P. Kofstad, Oxidation of metals: determination of activation energies. Nature 179, 1957 (1362–1363).

Thermo-Calc Software. TCOX9: TCS metal oxide solutions database, vol. 7, 1992.

F. Qayyum, M. Shah, S. Manzoor, and M. Abbas, Comparison of thermomechanical stresses produced in work rolls during hot and cold rolling of cartridge brass 1101. Materials on Science Technology 31, 2015 (317–324).

E. Kaschnitz, P. Hofer-Hauser, and W. Funk, Electrical resistivity measured by millisecond pulse-heating in comparison to thermal conductivity of the hot work tool steel AISI H11 (1.2343) at elevated temperature. High Temperature on High Press 49, 2020 (75–87).

J. I. Arrizubieta, M. Cortina, A. Mendioroz, A. Salazar, and A. Lamikiz, Thermal diffusivity measurement of laser-deposited AISI H13 tool steel and impact on cooling performance of hot stamping tools. Metals (Basel) 2020, 2020 (10).

H. J. Grabke, M. Spiegel, and A. Zahs, Role of alloying elements and carbides in the chlorine-induced corrosion of steels and alloys. Materials on Research 7, 2004 (89–95).

L. B. Susanto and D. J. Young, Effect of carbide volume fraction on the oxidation of austenitic Fe–Cr–C alloys. Materials on Corrosion 57, 2006 (467–475).

Acknowledgements

Funding was provided by the Slovenian Research Agency ARRS program P2-0344 (B) and P2-0050 (C).

Author information

Authors and Affiliations

Contributions

Conceptualization: Tilen Balaško; Methodology, formal analysis, and investigation: Tilen Balaško, Jaka Burja and Barbara Šetina Batič; Writing—original draft preparation: Tilen Balaško and Jaka Burja; Writing—review, editing and supervision: Maja Vončina and Jožef Medved.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Balaško, T., Vončina, M., Burja, J. et al. High-Temperature Oxidation Behavior of Tool Steel with Increased Thermal Conductivity. Oxid Met 98, 135–161 (2022). https://doi.org/10.1007/s11085-022-10119-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11085-022-10119-1