Abstract

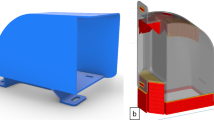

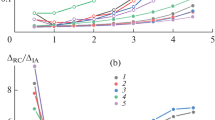

Optical decarburization measurements are preferred for quality tests, modeling, or indirect methods over carbon steel products. The measurements are commonly done by metallographs and can be supported by image processing. Image processing allows the collection of multiple measurements from digital micrographs. Nevertheless, limited attention has been paid to observing the influence of the segmentation methods on the precision of the depth measurements. The present paper uses type 1045 steel micrographs to examine the impact of the segmentation method parameters on the precision of depth measurements obtained with image processing. The micrographs are processed by a median filter and statistical region merging process. Then, a script is utilized to obtain 2,560 measurements per micrograph. The data is used to depict visual results of the decarburized zones and detailed statistical analysis. Eventually, image processing and manual measurements are compared to denote the reproducibility of the method. The paper concludes that the segmentation parameter can be used to measure complete or total decarburized zones for further analysis.

Similar content being viewed by others

References

M. Zorc, A. Nagode, J. Burja, B. Kosec, and B. Zorc, Surface decarburization of the hypo-eutectoid carbon steel C45 during annealing in steady air at temperatures T> AC1. Metals, Vol. 8, No. 6, pp. 425, 2018. https://doi.org/10.3390/met8060425.

G.F. Vander Voort, Understanding and measuring decarburization. Advanced Materials and Process, pp. 22–27, 2015

P. Szobota, M. Sepsi, and V. Mertinger, in Non-destructive Test for Control of the Surface Quality of Semi Product at the Automotive Industry, eds. K. Jármai and K. Voith, Vehicle and automotive engineering, Series Title: Lecture Notes in Mechanical Engineering Vol. 3 (Springer Singapore, Singapore, 2021) pp. 112–122. http://link.springer.com/10.1007/978-981-15-9529-5_10.

C. Ren, et al. Enhanced bending fatigue resistance of a 50CrMnMoVNb spring steel with decarburized layer by surface spinning strengthening. International Journal of Fatigue, Vol. 124, pp. 277–287, 2019. https://doi.org/10.1016/j.ijfatigue.2019.03.014.

ASTM International. Astm e1077-14, standard test methods for estimating the depth of decarburization of steel specimens. Technical report, West Conshohocken, PA, 2014, 2005. www.astm.org.

R. Kuschmierz, et al., Optical, in situ, three-dimensional, absolute shape measurements in CNC metal working lathes. The International Journal of Advanced Manufacturing Technology, Vol. 84, No. 9–12, pp. 2739–2749, 2016. https://doi.org/10.1007/s00170-015-8234-4.

W. Huang, C. S. Wang, Y.F. Chang, and C.M. Yeh, A digital analysis approach for estimating decarburization layer depth of carbon steel via a portable device. IOP Conference Series: Materials Science and Engineering 644, 012007, 2019. https://doi.org/10.1088/1757-899X/644/1/012007.

J. Schindelin, et al. Fiji: an open-source platform for biological-image analysis. Nature Methods 9(7), 676–682, 2012.

X. Liu, et al, A numerical model to predict scale formation in an industrial reheat Furnace. Iron and Steel Technology, pp. 3045–3054, 2018.

H. D., Alvarenga, T. V., De Putte, N., Van Steenberge, J., Sietsma, and H. Terryn, Influence of carbide morphology and microstructure on the kinetics of superficial decarburization of C–Mn steels. Metallurgical and Materials Transactions A: Physical Metallurgy and Materials Science, Vol. 46, No. 1, pp. 123–133, 2015. https://doi.org/10.1007/s11661-014-2600-y.

F. Zhao, C.L. Zhang, Y.Z. Liu, Ferrite decarburization of high silicon spring steel in three temperature ranges. Archives of Metallurgy and Materials Vol. 61, No. 3, pp. 1369–1376, 2016. https://doi.org/10.1515/amm-2016-0252.

Z. J., Tao, F. Rakotovao, J.L. Grosseau-Poussard, B. Panicaud, Determination of stress fields and identification of thermomechanical parameters in a thermally grown oxide under thermal cycling loadings, using advanced models. Advanced Materia Research, Vol. 996, pp. 896–901, 2014. https://doi.org/10.4028/www.scientific.net/AMR.996.896.

L. Suárez, Y. Houbaert, X. Vanden Eynde, R. Colás, Development of an experimental device to study high temperature oxidation. Oxidation of Metals, Vol. 70, No. 1–2, pp. 1–13, 2008. https://doi.org/10.1007/s11085-008-9105-2.

Chávez-Campos, G. M. et al. A Sample Size Statistical Analysis and Its Impact on Decarburization Measurements Metrics. JOM 73(7), 2031–2038 (2021). https://doi.org/10.1007/s11837-021-04697-9.

S.A. Villar, S. Torcida, G.G. Acosta, Median filtering: a new insight. Journal of Mathematical Imaging and Vision Vol. 58, No. 1, pp. 130–146, 2017. https://doi.org/10.1007/s10851-016-0694-0.

R. Nock, F. Nielsen, Statistical region merging. IEEE Transactions on Pattern Analysis and Machine Intelligence Vol. 26, No. 11, pp. 1452–1458, 2004. https://doi.org/10.1109/TPAMI.2004.110.

Python Documentation. Documentation of pandas.DataFrame.boxplot, pandas 1.4.1. https://pandas.pydata.org/docs/reference/api/pandas.DataFrame.boxplot.html.

M. Spitzer, J. Wildenhain, J. Rappsilber, R. BoxPlot, a web tool for generation of box plots, Vol. 11, No. 2, pp. 121–122. https://doi.org/10.1038/nmeth.2811.

Acknowledgements

The authors would like to thank to the National Laboratory “SEDEAM” for supporting this research through the equipment available in the solid-gas laboratory. This research is also supported by the “Tecnológico Nacional de México” TecNM-ITM through the founding 5441.19-P.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Chávez-Campos, G.M., Reyes-Archundia, E., Vergara-Hernández, H.J. et al. Improving Selectivity on High-Temperature Decarburization Depth Measurements using an Image Segmentation Method. Oxid Met 98, 121–134 (2022). https://doi.org/10.1007/s11085-022-10113-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11085-022-10113-7