Abstract

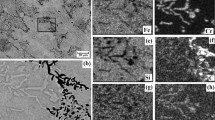

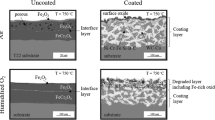

A thick silicon-enriched layer was formed on the surface of Fe and Fe-15 mass% Cr alloys by Si electrodeposition using a molten salt as the medium. This surface-treated sample was embedded in the molten salt and the high-temperature corrosion behavior was investigated. For comparison, the high-temperature corrosion behavior of untreated samples was also investigated. The effect of the surface Si conversion by the molten salt electrodeposition treatment on the high-temperature corrosion resistance of the Fe and Fe-15 mass% Cr alloys was then evaluated. As a result, the surface Si electrodeposition-treated Fe did not improve the corrosion resistance as compared to the untreated sample. However, for the Fe-15 mass% Cr alloy, the untreated corrosion weight loss sharply increased and the corrosion rate increased. On the other hand, the corrosion rate was lower on the surface of the Si-treated sample. After the high-temperature corrosion test, a cross section of the sample to which the molten salt was attached was observed and analyzed by SEM and EPMA. As a result, in the untreated sample of Fe, the elemental metal dissolved in the molten salt. In the Si electrodeposition-treated Fe, cracks were generated at the Fe interface between the electrodeposition layer and the substrate, and corrosion proceeded from there. On the other hand, for the Fe-15 mass% Cr alloy, it was confirmed that the surface Si-treated sample formed a continuous SiO2 layer on the surface. It is considered that this SiO2 improved the corrosion resistance.

Similar content being viewed by others

References

T. R. Miles, T. R. Miles, L. L. Baxter, R. W. Bryers, B. M. Jenkins, and L. L. Oden, Biomass and Bioenergy 10, 1996 (125).

H. P. Michelsen, F. Frandsen, K. Dam-Johansen, and O. H. Larsen, Fuel Processing Technology 54, 1998 (95).

H. P. Nielsen, F. J. Frandsen, K. Dam-Johansen, and L. L. Baxter, Progress in Energy and Combustion Science 26, 2000 (283).

Y. Kawahara, Corrosion Science 44, 2002 (223).

S. Enestam, D. Bankiewicz, J. Tuiremo, K. Mäkelä, and M. Hupa, Fuel 104, 2013 (294).

J. Metsäjoki, E. Huttunen-Saarivirta, and T. Lepistö, Fuel 133, 2014 (173).

K. L. Khatri, A. R. Muhammad, S. A. Soomro, N. A. Tunio, and M. M. Ali, Renewable and Sustainable Energy Reviews 143, 2021 (110862).

L. A. Hansen, H. P. Nielsen, F. J. Frandsen, K. Dam-Johansen, S. Hørlyck, and A. Karlsson, Fuel Processing Technology 64, 2000 (189).

Y. Shinata and Y. Nishi, Oxidation of Metals 26, 1986 (201).

B. P. Mohanty and A. A. Shores, Corrosion Science 46, 2004 (2893).

D. A. Shores and B. P. Mohanty, Corrosion Science 46, 2004 (2909).

H. Singh, D. Puri, and S. Prakash, Surface and Coating Technology 192, 2005 (27).

C. Pettersson, J. Pettersson, H. Asteman, J.-E. Svensson, and L.-G. Johansson, Corrosion Science 48, 2006 (1368).

H. T. Ma, C. H. Zhou, and L. Wang, Corrosion Science 51, 1861 (2009).

J. Pettersson, J.-E. Svensson, and L.-G. Johansson, Oxidation of Metals 72, 2009 (159).

J. Zhang, Z. Rahman, X. Wang, Z. Wang, P. Li, Y. Wang, D. Bate, K. Zhao, and H. Tan, Journal of Environmental Management 263, 2020 (110411).

Y. S. Zhang, Journal of Electrochemical Society 133, 1986 (655).

D. Z. Shi and R. A. Rapp, Journal of Electrochemical Society 133, 1986 (849).

R. A. Rapp, Corrosion Science 44, 2002 (209).

T. Ishitsuka and K. Nose, Corrosion Science 44, 2002 (247).

M. Fukumoto, T. Suzuki, M. Sano, M. Hirade, and M. Hara, Materials Transaction 45, 2004 (2994).

T. Munisamy and A. J. Bard, Electrochimica Acta 55, 2010 (3797).

K. Yasuda, K. Maeda, R. Hagiwara, T. Homma, and T. Nohira, Journal of the Electrochemical Society 164, 2017 (D67).

N. Shah and I. Mukhopadyay, Materialstoday: Proceedings 4, 2017 (12716).

M. Fukumoto, M. Hara, and T. Nagataki, Oxidation of Metals 61, 2004 (1).

M. Fukumoto, R. Yamashita, and M. Hara, Oxidation of Metals 62, 2004 (309).

M. Hara, Y. Matsuda, M. Fukumoto, and T. Narita, Oxidation of Metals 70, 2008 (295).

M. Fukumoto, C. Tachikawame, Y. Matsuzaka, and M. Hara, Corrosion Science 56, 2012 (105).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Fukumoto, M., Nakajima, K. & Sakuraba, T. Formation of Si Diffusion Layer on Fe and Fe–Cr Alloy and High-Temperature Corrosion Resistance in a Molten Salt. Oxid Met 97, 401–415 (2022). https://doi.org/10.1007/s11085-021-10096-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11085-021-10096-x