Abstract

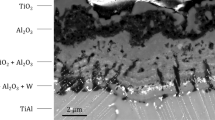

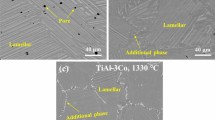

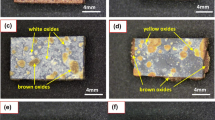

The oxidation resistance of TiAl alloy is still a problem in air above 800 ℃. Gadolinium is an active element which is known to improve the oxidation resistance of Mg alloy. Very dense TiAl-Gd alloys with several compositions were prepared by spark plasma sintering (SPS). Isothermal oxidation testing of sintered alloy in air at 800 ℃ was carried out for 500 h. The sintering microstructure, oxidation kinetics, oxide-layer structure and oxidation mechanism were systematically studied. The results show that Gd-containing TiAl alloy shows improved oxidation resistance at high temperature compared with alloy without Gd. The Gd-rich phase distributed along the boundary of powder particles can hinder the outward diffusion of Ti and Al and preferentially consume oxygen in the matrix, thus inhibiting the growth of oxide scale and improving the spalling resistance of TiAl alloy. TiAl-0.3Gd alloy has excellent oxidation resistance, with the lowest mass gain and the thinnest oxide scale of 2.64 mg/cm2 and 19.7 μm, respectively. This result will lay a foundation for the design of TiAl-based alloy with high-temperature oxidation resistance.

Similar content being viewed by others

References

H. Sun, Z. Wang, Y. Du, and J. Yuan, Densification mechanism and microstructure evolution of Ti-48Al-2Cr-8Nb alloy by spark plasma sintering. Cryst Res Technol. 54, (11), 2019 (1900107).

H. W. Liu, D. P. Bishop, and K. P. Plucknett, Densification behaviour and microstructural evolution of Ti-48Al consolidated by spark plasma sintering. J Mater Sci. 52, 2017 (613–627).

R. Muñoz-Moreno, E. M. Ruiz-Navas, B. Srinivasarao, and J. M. Torralba, Microstructural development and mechanical properties of PM Ti–45Al–2Nb–2Mn–0.8 vol.%TiB2 processed by field assisted hot pressing. Journal of Materials Science and Technology. 230, 2014 (1145–1154).

M. P. Bacos, S. Ceccacci, J. P. Monchoux, et al., Oxidation behavior of a spark plasma sintered Ti–48Al–2W–0.1B alloy at 800 °C. Oxid Met. 93, 2020 (587–600).

Y. Garip and O. Ozdemir, A study of the cycle oxidation behavior of the Cr/Mn/Mo alloyed Ti–48Al–based intermetallics prepared by ECAS. J Alloys Compd. 818, 2020 (152818).

P. V. Cobbinah, W. Matizamhuka, R. Machaka, M. B. Shongwe, and Y. Yamabe-Mitarai, The effect of Ta additions on the oxidation resistance of SPS-produced TiAl alloys. Int J Adv Manuf Tech. 106, 2020 (3203–3215).

N. Laska, R. Braun, and S. Knittel, Oxidation behavior of protective Ti-Al-Cr based coatings applied on the γ-TiAl alloys Ti-48-2-2 and TNM-B1. Surf Coat Technol. 349, 2018 (347–356).

K. Zhang, L. Xin, Y. Lu, et al., Improving oxidation resistance of γ-TiAl based alloy by depositing TiAlSiN coating: effects of silicon. Corros Sci. 179, 2021 (109151).

R. Swadźba, L. Swadźba, B. Mendala, P.-P. Bauer, N. Laska, and U. Schulz, Microstructure and cyclic oxidation resistance of Si-aluminide coatings on γ-TiAl at 850 ℃. Surf Coat Technol. 403, 2020 (126361).

P. Zhao, X. Li, H. Tang, et al., Improved high-temperature oxidation properties for Mn-containing Beta-Gamma TiAl with W addition. Oxid Met. 93, 2020 (433–448).

L. L. Zhao, G. Y. Li, L. Q. Zhang, et al., Influence of Y addition on the long time oxidation behaviors of high Nb containing TiAl alloys at 900 °C. Intermetallics. 18, 2010 (1586–1596).

Y. Pan, X. Lu, M. D. Hayat, et al., Effect of Sn addition on the high-temperature oxidation behavior of high Nb-containing TiAl alloys. Corros Sci. 166, 2020 (108449).

D. Pilone, F. Felli, and A. Brotzu, High temperature oxidation behaviour of TiAl-Cr-Nb-Mo alloys. Intermetallics. 43, 2013 (131–137).

Y. Pan, X. Lu, T. Hui, et al., High-temperature oxidation behaviour of TiAl alloys with Co addition. J Mater Sci. 56, 2020 (815–827).

X. Gu, F. Cao, N. Liu, et al., Microstructural evolution and mechanical properties of a high yttrium containing TiAl based alloy densified by spark plasma sintering. J Alloys Compd. 819, 2020 (153264).

X. Gu, S. Jiang, F. Cao, et al., A β-solidifying TiAl alloy reinforced with ultra-fine Y-rich precipitates. Scr Mater 192, 2021 (55–60).

V. A. C. Haanappel, H. Clemens, and M. F. Stroosnijdera, The high temperature oxidation behaviour of high and low alloyed TiAl-based intermetallics. Intermetallics. 10, 2002 (293–305).

P. V. Panin, A. S. Kochetkov, A. V. Zavodov, and E. A. Lukina, Effect of Gd addition on phase composition, structure, and properties of beta-solidifying TiAl-based alloy with Zr and Cr content variability. Intermetallics. 121, 2020 (106781).

V. S. Sokolovsky, N. D. Stepanov, S. V. Zherebtsov, et al., The effect of Gd addition on the kinetics of α2→γ transformation in γ-TiAl based alloys. Intermetallics. 120, 2020 (106759).

K. Xia, X. Wu, and D. Song, Effects of Gd addition, lamellar spacing and loading direction on creep behaviour of a fully lamellar Ti-44Al-1Mn-2.5Nb alloy. Acta Mater. 52, 2004 (841–849).

R. Ding, I. P. Jones, Y. Chiu, and R. Chen, Microstructure and mechanical property of directionally solidified Ti-46Al-0.5W-0.5Si alloys with and without Gd. Intermetallics. 20, 2012 (123–134).

C. Cheng, Q. Lan, Q. Liao, et al., mEffect of Ca and Gd combined addition on ignition temperature and oxidation resistance of AZ80. Corros Sci. 160, 2019 (108176).

Z. Trzaska, G. Bonnefont, G. Fantozzi, and J. P. Monchoux, Comparison of densification kinetics of a TiAl powder by spark plasma sintering and hot pressing. Acta Mater. 135, 2017 (1–13).

C. Shi, K. Zhang, Z. Lu, and H. Xiao, Microstructure evolution and mechanical properties of Ti46.5Al2Cr1.8Nb-(W, B) alloys fabricated by spark plasma sintering and pulse current assisted isothermal forging. Mater Sci Eng. A. 747, 2019 (98–110).

A. Couret, T. Voisin, M. Thomas, and J.-P. Monchoux, Development of a TiAl Alloy by Spark Plasma Sintering. JOM. 69, 2017 (2576–2582).

Y. Garip, Investigation of isothermal oxidation performance of TiAl alloys sintered by different processing methods. Intermetallics. 127, 2020 (106985).

L. Mengis, A. S. Ulrich, P. Watermeyer, C. H. Liebscher, and M. C. Galetz, Oxidation behaviour and related microstructural changes of two β0–phase containing TiAl alloys between 600 °C and 900 °C. Corros Sci. 178, 2021 (109085).

D. Zhang, N. Liu, Y. Chen, et al., Microstructure Evolution and Mechanical Properties of PM-Ti43Al9V0.3Y. Alloy Materials. 13, (1), 2020 (198).

S. Tian, H. Jiang, G. Zhang, Y. Zhang, H. Lin, and Y. Yang, Investigation on the initial oxidation behavior of TiAl. Alloy Mater Res Express. 6, (10), 2019 (106595).

Y. MIishin and C. Herzig, Diffusion in the Ti-Al system. Acta Mater. 48, 2000 (589–623).

N. S. Neelam, S. Banumathi, A. Bhattacharjee, N. R. Zafir, and M. D. Alam, Comparison of the isothermal and cyclic oxidation behavior of Cr and Mo containing γ-TiAlNb alloys. Corros Sci. 163, 2020 (108300).

X. Wang, R. Luo, F. Liu, et al., Characterization of Gd-rich precipitates in a fully lamellar TiAl alloy. Scr Mater. 137, 2017 (50–54).

Y. Wu, Y. Umakoshi, X. W. Li, and T. Narita, Isothermal oxidation behavior of Ti-50Al alloy with Y additions at 800 and 900°C. Oxid Met. 66, 2006 (321–348).

Y. Garip and O. Ozdemir, Comparative study of the oxidation and hot corrosion behaviors of TiAl-Cr intermetallic alloy produced by electric current activated sintering. J Alloys Compd. 780, 2019 (364–377).

R. Swadźba, K. Marugi, and Ł Pyclik, STEM investigations of γ-TiAl produced by additive manufacturing after isothermal oxidation. Corros Sci. 169, 2020 (108617).

F. P. Ping, Q. M. Hu, A. V. Bakulin, S. E. Kulkova, and R. Yang, Alloying effects on properties of Al2O3 and TiO2 in connection with oxidation resistance of TiAl. Intermetallics. 68, 2016 (57–62).

D. J. Kim, D. Y. Seo, J. K. Hong, S. E. Kim, and D. Y. Keum, Cyclic-oxidation behaviours of the powder-metallurgy TiAl-4Nb-3Mn and TiAl-2Nb-2Mo beta-gamma alloys. Can Metall Q. 56, 2016 (123–136).

Y. Tan, H. Fang, R. Chen, et al., Microalloying effects of Ho on microstructure evolution and high temperature properties of Ti46Al4Nb1Mo alloy. Intermetallics. 126, 2020 (106883).

Zhang GY, Liu CM, Fang GL (2017) First principles studies of the influences mechanism of Y, Hf elements on the high temperature oxidation of γ-TiAl alloys. In: IOP Conference Series: Materials Science and Engineering. 167(1):012049

Y. Wu, S. K. Hwang, K. Hagihara, and Y. Umakoshi, Isothermal oxidation behavior of two-phase TiAl-Mn-Mo-C-Y alloys fabricated by different processes. Intermetallics 14, 2006 (9–23).

X. Gong, R. R. Chen, H. Z. Fang, et al., Synergistic effect of B and Y on the isothermal oxidation behavior of TiAl-Nb-Cr-V alloy. Corros Sci. 131, 2018 (376–385).

Acknowledgements

This research was sponsored by the National Key Research and Development Program of China (No. 2016YFB1200505) and Cultivation project for original scientific research instruments and equipment of Southwest Jiaotong University (NO. XJ2021KJZK041).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Guo, Q., Sun, H., Cai, Z. et al. The Effect of Gd Additions on the Oxidation Resistance of TiAl Alloys Prepared by SPS. Oxid Met 97, 323–339 (2022). https://doi.org/10.1007/s11085-021-10095-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11085-021-10095-y