Abstract

In this research, an attempt was made to investigate the short-time oxidation of Al–Mg melt using oxide/metal/oxide sandwich method. Samples were produced by controlled blowing of bubbles with the pressure of 0.2 atm through the aluminum melt containing 1, 3 and 5.5 weight percent of Mg at 670 °C. Various characteristics of dynamically formed oxide films such as wrinkles, folds, holes, cracks and re-oxidation patterns were studied through microscopic analysis. It appeared that re-oxidation patterns are the main features of the dynamically formed oxide films. Also, separation of oxide films in the oxide/oxide interface and loose connections with the paired metal were other important phenomena. Thickness of the oxide films was measured to be 19, 31 and 51 nm for Al–1 Mg, Al–3 Mg, and Al–5.5 Mg samples, respectively. Thermodynamic-based considerations revealed the formation of MgO, MgAl2O4 and Al2O3 as possible product of the oxidation within the range of this study. However, MgAl2O4 was only detected in Al–1 Mg and Al–3 Mg samples based on XRD analysis while there was no evidence of Al2O3 formation at all. Furthermore, MgO was the main oxide in both Al–3 Mg and Al–5.5 Mg sandwich samples. High concentration and activity of magnesium at the surface of the melt along with the turbulent situation and short time duration of the oxidation process can be considered as the main discrepancy cause between thermodynamics and experimental results.

Similar content being viewed by others

Availability of Data and Material

The raw/processed data required to reproduce these findings cannot be shared at this time as the data also form part of an ongoing study.

References

G. M. Scamans and E. P. Butler, In situ observations of crystalline oxide formation during aluminum and aluminum alloy oxidation. Metallurgical Transactions A. 6, (11), 1975 (2055–2063).

M. H. Zayan, O. M. Jamjoom and N. A. Razik, High-temperature oxidation of Al–Mg alloys. Oxidation of Metals. 34, (3), 1990 (323–333).

J. A. S. Tenório and D. C. R. Espinosa, High-temperature oxidation of Al–Mg alloys. Oxidation of Metals. 53, (3), 2000 (361–373).

K. Wefers. Oxides and hydroxides of aluminum. 1987; Aloca Laboratories. 100.

W. Thiele, Die oxydation von aluminium und aluminiumlegierungs schmelzen. Aluminium 38, (11), 1962 (1–18).

C. N. Cochran, D. L. Belitskus and D. L. Kinosz, Oxidation of aluminum-magnesium melts in air, oxygen, flue gas, and carbon dioxide. Metallurgical Transactions B 8, (1), 1977 (323–332).

E. N. Coker. The oxidation of aluminum at high temperature studied by Thermogravimetric Analysis and Differential Scanning Calorimetry. 2013; Sandia National Laboratories: Albuquerque, New Mexico.

G. Wu, K. Dash, M. L. Galano and K. A. Q. O’Rilly, Oxidation studies of Al alloys: part II Al–Mg alloy. Corrosion Science 155, 2019 (97–108).

I. Haginoya and T. Fukusako, Oxidation of molten Al–Mg alloys. Transactions of the Japan Institute of Metals 24, (9), 1983 (613–619).

S. H. Ha, Y. O. Yoon, B. H. Kim, H. K. Lim, T. W. Lee, S. H. Lim and S. K. Kim, Pilling-Bedworth ratio approach to surface oxidation of Al–Mg alloys containing Al2Ca and its experimental verification. Science of Advanced Materials 10, (5), 2018 (697–700).

K. Surla, F. Valdivieso, M. Pijolat, M. Soustelle and M. Prin, Kinetic study of the oxidation by oxygen of liquid Al–Mg 5% alloys. Solid State Ionics. 143, (3), 2001 (355–365).

M. Drouzy and C. Mascré, The oxidation of liquid non-ferrous metals in air or oxygen. Metallurgical Reviews 14, (1), 1969 (25–46).

G. Wightman and D. J. Fray, The dynamic oxidation of aluminum and its alloys. Metallurgical Transactions B. 14, (4), 1983 (625–631).

J. Campbell, Castings, 2nd ed, (Butterworth-Heinemann, Oxford, 2003).

W. D. Griffiths and N. W. Lai, Double oxide film defects in cast magnesium alloy. Metallurgical and Materials Transactions A 38, (1), 2007 (190–196).

D. Dispinar and J. Campbell, Critical assessment of reduced pressure test. Part 2: Quantification. International Journal of Cast Metals Research. 17, (5), 2004 (287–294).

M. A. El-Sayed, H. A. G. Salem, A. Y. Kandeil and W. D. Griffith, Effect of holding time before solidification on double-oxide film defects and mechanical properties of aluminum alloys. Metallurgical and Materials Transactions B. 42, (6), 2011 (1104–1109).

T. Tunçay, S. Tekeli, O. Dursun and D. Dispinar, Microstructure–bifilm interaction and its relation with mechanical properties in A356. International Journal of Cast Metals Research 30, (1), 2017 (20–29).

G. Eisaabadi Bozchaloei, N. Varahram, P. Davami and S. K. Kim, Effect of oxide bifilms on the mechanical properties of cast Al–7Si–0.3 Mg alloy and the roll of runner height after filter on their formation. Materials Science and Engineering A 548, 2012 (99–105).

J. Campbell. Update on bifilms-the fundamental defect in metals. Shape Casting. 2019; 3-15.

X. Cao and J. Campbell, The nucleation of Fe-Rich phases on oxide films in Al–11.5Si-0.4 Mg cast alloys. Metallurgical and Materials Transactions A 34, (7), 2003 (1409–1420).

M. Divandari and J. Campbell, Oxide film characteristics of Al–7Si–Mg alloy in dynamic conditions in casting. International Journal of Cast Metals Research 17, (3), 2004 (182–187).

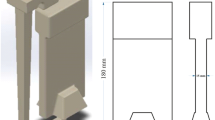

M. Divandari, J. Campbell. A new technique for the study of aluminum oxide films. Aluminum Transaction. 1999: p. 233-238.

M. Jalilvand, N. Taheri Bagh, M. Akbarifar, M. Divandari. A new Insight to dynamic oxidation of molten metals by the parametric study of oxide/metal/oxide sandwich formation. International Journal of Metalcasting (2019).

C. W. Bale, E. Belisle, P. Chartrand, S. A. Decterov, G. Eriksson, A. E. Gheribi, et al., FactSage thermochemical software and databases, 2010–2016. Calphad 54, 2016 (35–53).

M. Divandari and J. Campbell, Morphology of oxide films of Al–5 Mg alloy in dynamic conditions in casting. International Journal of Cast Metals Research 18, (3), 2005 (187–192).

G. Grimvall, Thermophysical Properties of Materials, (Elsevier, Amsterdam, 1999).

M. A. Durand, The coefficient of thermal expansion of magnesium oxide. Journal of Applied Physics 7, 1936 (297–298).

A. R. Mirak, M. Divandari, S. M. A. Boutorabi and J. Campbell, Oxide film characteristics of AZ91 magnesium alloy in casting conditions. International Journal of Cast Metals Research 20, (4), 2007 (215–220).

S. A. Azarmehr, M. Divandari and H. Arabi, Investigation on thickness of short time oxide films in Al–1 Mg and Al–2 Mg alloys. Materials Science and Technology 28, (11), 2012 (1295–1300).

M. M. Jalilvand, M. Akbarifar, M. Divandari and H. Saghafian, On the dynamically formed oxide films in molten Mg. Journal of Magnesium and Alloys 8, (1), 2020 (219–230).

N. Taheri Bagh, M. Divandari, M. Shahmiri and M. Akbarifar, Characteristics of dynamically formed oxide films in Al–Zn melt. International Journal of Metalcasting 2020. https://doi.org/10.1007/s40962-020-00501-7.

M. Tiryakioğlu, P. Yousefian and P. D. Eason, Quantification of entrainment damage in A356 aluminum alloy castings. Metallurgical and Materials Transactions A 49, (11), 2018 (5815–5822).

J. Campbell, Complete Casting Handbook Metal Casting Processes, Metallurgy, Techniques and Design, (Butterworth-Heinemann, Oxford, 1979).

J. Liu, Q. Wang, Y. Qi. Connecting oxide bifilms properties from atomistic simulations with virtual casting of aluminum. Shape Casting, 45–51 (2019).

J. Liu, Q. Wang and Y. Qi, Atomistic simulation of the formation and fracture of oxide bifilms in cast aluminum. Acta Materialia 164, 2019 (673–682).

H. Bartar Esfahani, H. Doostmohammadi and R. Raiszadeh, Decrease in the rate of diffusion of hydrogen through layers of bifilm defects in Al melt in the presence of Sr. International Journal of Cast Metals Research 29, (3), 2016 (179–185).

M. Divandari and M. Mehrabian, A comparative study on characteristics of dynamic oxide film of molten Zn-Al alloys. Iranian Journal of Materials Science and Engineering 14, (3), 2017 (34–47).

E. Panda, L. P. H. Jeurgens and E. J. Mittemeijer, Growth kinetics and mechanism of the initial oxidation of Al–based Al–Mg alloys. Corrosion Science 52, (8), 2010 (2556–2564).

K. Shimizu, et al., On the nature of “easy paths” for the diffusion of oxygen in thermal oxide films on aluminum. Oxidation of Metals 35, (5), 1991 (427–439).

A. Nylund, K. Mizuno and I. Olefjord, Influence of Mg and Si on the oxidation of aluminum. Oxidation of Metals 50, (3), 1998 (309–325).

D. J. Field and G. M. Scamans, EP Butler, The high temperature oxidation of Al–4.2 wt pct Mg alloy. Metallurgical Transactions A 18, (3), 1987 (463–472).

Y. O. Yoon, S. H. Ha, H. K. Bong, H. K. Lim, K. K. Shae. Experimental investigation of MgAl2O4 spinel formation in oxidation of Al–Mg alloys. Light Metals 2020 (2020).

T. S. Shih, Thermally-formed oxide on aluminum and magnesium. Materials Transactions 47, (5), 2006 (1347–1353).

S. Amirinejhad, R. Raiszadeh and H. Doostmohammadi, Study of double oxide film defect behavior in liquid Al–Mg alloys. International Journal of Cast Metals Research 26, (6), 2013 (330–338).

N. Smith, A. Kvithyld and G. Tranell, The mechanism behind the oxidation protection of high Mg-Al alloys with beryllium. Metallurgical and Materials Transactions B 49, 2018 (2846–2857).

Funding

Not applicable.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Akbarifar, M., Divandari, M., Boutorabi, S.M.A. et al. Short-Time Oxidation of Al–Mg in Dynamic Conditions. Oxid Met 94, 409–429 (2020). https://doi.org/10.1007/s11085-020-09999-y

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11085-020-09999-y