Abstract

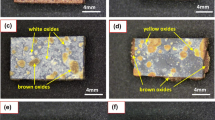

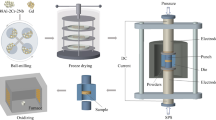

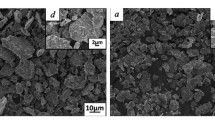

Spark plasma sintering (SPS) enables the manufacturing of TiAl alloys with an exceptional combination of low density and mechanical properties such as acceptable ductility at room temperature and high strength at high temperature. However, TiAl alloys are known to exhibit low oxidation resistance above 700 °C. The oxidation of a Ti–48Al–2W–0.1B (at. %) processed by SPS was investigated at 800 °C. Coupons were oxidized in air and in Ar-21O2 (vol%), in isothermal and cyclic tests. In air, the alloy formed a mixture of Ti and Al oxides, but oxidation was slower than typically observed for W-free alloys. The oxide scale and underlying alloy were characterized by X-ray diffraction and electron microscopy in order to examine the beneficial role of W in the oxidation resistance. The main constituents of the reaction product after reaction in air may be described as follows (from gas to alloy): TiO2/porous Al2O3/TiO2 + Al2O3/TiN + Al2O3 + W/TiAl2 + W/TiAl. Close examination suggests that the relatively good oxidation resistance of the alloy is related to W doping of TiO2 in the mixed Al2O3 + TiO2 layer. The alloy formed an Al-rich oxide scale with much slower kinetics in Ar-21O2, confirming the detrimental role of N in the oxidation process.

Graphic Abstract

Similar content being viewed by others

Availability of Data and Material

The raw/processed data required to reproduce these findings cannot be shared at this time due to technical or time limitations.

References

T. Voisin, J.-P. Monchoux, L. Durand, N. Karnatak, M. Thomas and A. Couret, Advanced Engineering Materials17, 2015 (1408–1413). https://doi.org/10.1002/adem.201500019.

M. Thomas and M. P. Bacos, AerospaceLab3, 2011 (1–11).

Y. Shida and H. Anada, Corrosion Science35, 1993 (945–953). https://doi.org/10.1016/0010-938X(93)90313-6.

T. Voisin, J.-P. Monchoux, M. Perrut and A. Couret, Intermetallics71, 2016 (88–97). https://doi.org/10.1016/j.intermet.2016.01.003.

R. Pflumm, A. Donchev, S. Mayer, H. Clemens and M. Schütze, Intermetallics53, 2014 (45–55). https://doi.org/10.1016/j.intermet.2014.04.010.

A. Donchev, M. Galetz, S. Mayer, H. Clemens and M. Schütze, MRS Advances2, 2017 (1361–1367). https://doi.org/10.1557/adv.2017.170.

D. Monceau and B. Pieraggi, Oxidation of Metals50, 1998 (477–493). https://doi.org/10.1023/a:1018860909826.

J. W. Fergus, Materials Science and Engineering: A338, 2002 (108–125). https://doi.org/10.1016/S0921-5093(02)00064-3.

R. Pflumm, S. Friedle and M. Schütze, Intermetallics56, 2015 (1–14). https://doi.org/10.1016/j.intermet.2014.08.002.

A. Rahmel, M. Schütze and W. J. Quadakkers, Materials and Corrosion46, 1995 (271–285). https://doi.org/10.1002/maco.19950460503.

C. Lang and M. Schütze, Materials and Corrosion48, 1997 (13–22). https://doi.org/10.1002/maco.19970480104.

F. Dettenwanger, E. Schumann, M. Ruhle, J. Rakowski and G. H. Meier, Oxidation of Metals50, 1998 (269–307). https://doi.org/10.1023/A:1018892422121.

V. Maurice, G. Despert, S. Zanna, P. Josso, M.-P. Bacos and P. Marcus, Acta Materialia55, 2007 (3315–3325). https://doi.org/10.1016/j.actamat.2007.01.030.

J. Graham and R. C. Morris, Mineralogical Magazine39, 1973 (470–473).

J.-O. Andersson, T. Helander, L. Höglund, P. Shi and B. Sundman, Calphad26, 2002 (273–312). https://doi.org/10.1016/S0364-5916(02)00037-8.

Y. Shida and H. Anada, Oxidation of Metals45, 1996 (197–219). https://doi.org/10.1007/BF01046826.

S. A. Kekare and P. B. Aswath, Journal of Materials Science32, 1997 (2485–2499). https://doi.org/10.1023/A:1018529829167.

S. Becker, A. Rahmel, M. Schorr and M. Schütze, Oxidation of Metals38, 1992 (425–464). https://doi.org/10.1007/BF00665663.

J. Magnan, G. C. Weatherly and M.-C. Cheynet, Metallurgical and Materials Transactions A30, 1999 (19–29). https://doi.org/10.1007/s11661-999-0192-8.

G. C. Rybicki and J. L. Smialek, Oxidation of Metals31, 1989 (275–304). https://doi.org/10.1007/bf00846690.

M. W. Brumm and H. J. Grabke, Corrosion Science33, 1992 (1677–1690). https://doi.org/10.1016/0010-938x(92)90002-k.

Acknowledgements

The authors would like to thank Claire Sanchez and Odile Lavigne (ONERA) for performing the XRD analysis and proofreading the manuscript, respectively.

Funding

This work was supported by the Direction Générale de l’Armement (DGA/Ministry of the Armed Forces).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

S1: Sequence of STEM-HAADF images of the TiO2 grains in the TiO2-Al2O3 layer formed on the IRIS alloy after 1000 cycles in air at 800 °C, showing intergranular W-rich particles. Supplementary file1 (AVI 6950 kb)

Rights and permissions

About this article

Cite this article

Bacos, MP., Ceccacci, S., Monchoux, JP. et al. Oxidation Behavior of a Spark Plasma Sintered Ti–48Al–2W–0.1B Alloy at 800 °C. Oxid Met 93, 587–600 (2020). https://doi.org/10.1007/s11085-020-09973-8

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11085-020-09973-8