Abstract

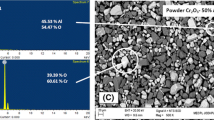

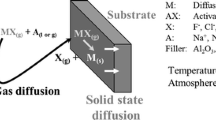

Due to the coal combustion that generates halides, steel components can confront hot corrosion during applications at high temperature. The hot-dipping aluminum (HDA) was operated on the 9Cr–Mo steel (grade 91) to form the iron aluminide layer. A hot corrosion-loading test of aluminized grade 91 (HDA-91) was carried out by covering a salt mixture of NaCl/Na2SO4 under static load ranging from 75 to 100 MPa at 600 °C and 700 °C, respectively. The failure mechanism was assessed after various elongations using scanning electron microscopy and optical microscopy. The results showed that HDA-91 presented higher hot corrosion resistance than the uncoated grade 91. The aluminide layer formed a higher ductility oxide and prevented the substrate form grain-boundary oxidation at high temperatures, resulting in durability. The results also revealed a significant improvement in reduction of area during the hot corrosion-loading test for grade 91 that underwent HDA treatment.

Similar content being viewed by others

References

C. J. Wang and S. M. Chen, Surface and Coatings Technology 200, 6601 (2006). https://doi.org/10.1016/j.surfcoat.2005.11.031.

D. Wang and Z. Shi, Applied surface science 227, 255 (2004). https://doi.org/10.1016/j.apsusc.2003.11.076.

H. R. Shahverdi, M. R. Ghomashchi, S. Shabestari and J. Hejazi, Journal of Materials Processing Technology 124, 345 (2002). https://doi.org/10.1016/S0924-0136(02)00225-X.

W. J. Cheng and C. J. Wang, Applied Surface Science 257, 4663 (2011). https://doi.org/10.1016/j.apsusc.2010.12.118.

A. V. Alboom, B. Lemmens, B. Breitbach, E. De Grave, S. Cottenier and K. Verbeken, Surface and Coatings Technology 324, 419 (2017). https://doi.org/10.1016/j.surfcoat.2017.05.091.

Y. Y. Chang, C. C. Tsaur, and J. C. Rock, Surface and Coatings Technology, 200, 6588 (2006). https://doi.org/10.1016/j.surfcoat.2005.11.038.

H. Springer, A. Kostka, J. F. D. Santos and D. Raabe, Materials Science and Engineering: A 528, 4630 (2011). https://doi.org/10.1016/j.msea.2011.02.057.

Z. X. Gui, K. Wang, Y. S. Zhang and B. Zhu, Applied surface science 316, 595 (2014). https://doi.org/10.1016/j.apsusc.2014.08.043.

D. J. Wu, W. G. Mao, Y. C. Zhou and C. S. Lu, Applied Surface Science 257, 6040 (2011). https://doi.org/10.1016/j.apsusc.2011.01.119.

U. Wiklund, P. Hedenqvist and S. Hogmark, Surface and Coatings Technology 97, 773 (1997). https://doi.org/10.1016/S0257-8972(97)00290-9.

W. J. Cheng and C. J. Wang, Applied Surface Science 274, 258 (2013). https://doi.org/10.1016/j.apsusc.2013.03.030.

C. C. Tsaur, J. C. Rock, C. J. Wang and Y. H. Su, Materials Chemistry and Physics 89, 445 (2005). https://doi.org/10.1016/j.matchemphys.2004.10.002.

W. J. Cheng and C. J. Wang, Applied Surface Science 277, 139 (2013). https://doi.org/10.1016/j.apsusc.2013.04.015.

C. T. Liu, V. K. Sikka, and C. G. McKamey. Alloy development of FeAl aluminide alloys for structural use in corrosive environments. No. ORNL/TM–12199. Oak Ridge National Lab., TN (United States) (1993).

H. C. Liang and C. J. Wang, Surface and Coatings Technology 350, 496 (2018). https://doi.org/10.1016/j.surfcoat.2018.05.093.

R. Viswanathan, K. Coleman and U. Rao, International Journal of Pressure Vessels and Piping 83, 778 (2006). https://doi.org/10.1016/j.ijpvp.2006.08.006.

Y. Fukuda, Materials Science Forum 696, 236 (2011). https://doi.org/10.4028/www.scientific.net/MSF.696.236.

P. Castello, V. Guttmann, N. Farr, and G. Smith, Materials and Corrosion, 51, 786 (2000). https://doi.org/10.1002/1521-4176(200011)51:11<786::AID-MACO786>3.0.CO;2-M.

G. Stein-Brzozowska, D. M. Flórez, J. Maier and G. Scheffknecht, Fuel 108, 521 (2013). https://doi.org/10.1016/j.fuel.2012.11.081.

S. Mahajan, and R. Chhibber, Engineering Failure Analysis 99, 210 (2019). https://doi.org/10.1016/j.engfailanal.2019.02.013.

T. Okada, Journal of the Electrochemical Society 131, 241 (1984). https://doi.org/10.1149/1.2115556.

I. G. Wright, and B. A. Pint, An Assessment of the High-Temperature Oxidation Behavior of Fe-Cr Steels in Water Vapor and Steam Paper 02377 presented at NACE CORROSION 2002, April, 2002 (Denver, CO).

R. Mittal and B. S. Sidhu, Journal of Materials Engineering and Performance 24, 670 (2015). https://doi.org/10.1007/s11665-014-1338-4.

L. Falat, L. Čiripová, J. Kepič, J. Buršík and I. Podstranská, Engineering Failure Analysis 40, 141 (2014). https://doi.org/10.1016/j.engfailanal.2014.02.018.

F. Masuyama, ISIJ international 41, 612 (2001). https://doi.org/10.2355/isijinternational.41.612.

B. Fournier, M. Sauzay and A. Pineau, International Journal of Plasticity 27, 1803 (2011). https://doi.org/10.1016/j.ijplas.2011.05.007.

R. Viswanathan, J. Sarver and J. M. Tanzosh, Journal of Materials Engineering and Performance 15, 255 (2006). https://doi.org/10.1361/105994906X108756.

K. Maruyama, K. Sawada and J. I. Koike, ISIJ international 41, 641 (2001). https://doi.org/10.2355/isijinternational.41.641.

A. Pardo, M. C. Merino, A. E. Coy, F. Viejo, R. Arrabal and E. Matykina, Corrosion Science 50, 780 (2008). https://doi.org/10.1016/j.corsci.2007.11.004.

K. Hashimoto, K. Asami, A. Kawashima, H. Habazaki and E. Akiyama, Corrosion Science 49, 42 (2007). https://doi.org/10.1016/j.corsci.2006.05.003.

H. E. Evans, Materials Science and Engineering: A 120, 139 (1989). https://doi.org/10.1016/0921-5093(89)90731-4.

V. Teixeira, Vacuum 64, 393 (2002). https://doi.org/10.1016/S0042-207X(01)00327-X.

B. F. Chen, J. Hwang, I. F. Chen, G. P. Yu and J. H. Huang, Surface and Coatings Technology 126, 91 (2000). https://doi.org/10.1016/S0257-8972(99)00669-6.

T. B. Massalski. Binary Alloy Phase Diagrams. vol. 3 (ASM International, 2874, 1992).

B. Lemmens, H. Springer, M. Peeters, I. De Graeve, J. De Strycker, D. Raabe and K. Verbeken, Materials Science and Engineering: A 710, 385 (2018). https://doi.org/10.1016/j.msea.2017.10.094.

C. J. Wang, Y. C. Chang and Y. H. Su, Oxidation of metals 59, 115 (2003). https://doi.org/10.1023/A:1023022100300.

R. W. Ashbrook and A. R. Marder, Metallurgical Transactions A 16, 897 (1985). https://doi.org/10.1007/BF02814841.

O. Underwood, J. Madison, R. M. Martens, G. B. Thompson, S. Welsh and J. Evans, Metallography, Microstructure, and Analysis 5, 302 (2016). https://doi.org/10.1007/s13632-016-0290-0.

M. Windmann, A. Röttger and W. Theisen, Surface and Coatings Technology 226, 130 (2013). https://doi.org/10.1016/j.surfcoat.2013.03.045.

L. Qian, S. Zhu, Y. Kagawa and T. Kubo, Surface and Coatings Technology 173, 178 (2003). https://doi.org/10.1016/S0257-8972(03)00429-8.

E. Tzimas and G. Papadimitriou, Surface and Coatings Technology 145, 179 (2001). https://doi.org/10.1016/S0257-8972(01)01323-8.

B. Fournier, M. Sauzay, C. Caës, M. Noblecourt, M. Mottot, A. Bougault, V. Rabeau and A. Pineau, International Journal of Fatigue 30, 663 (2008). https://doi.org/10.1016/j.ijfatigue.2007.05.008.

B. Fournier, M. Sauzay, C. Caës, M. Noblecourt, M. Mottot, A. Bougault and V. Rabeau, International Journal of Fatigue 30, 1797 (2008). https://doi.org/10.1016/j.ijfatigue.2008.02.006.

Acknowledgement

The authors are very grateful to the Ministry of Science and Technology of Republic of China for funding support Grant No. 107-2221-E-011-008-.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Liang, HC., Wang, CJ. Effect of Iron-Aluminide Coating on the Fracture Mechanism of Ferritic–Martensitic Steel in Coal-Fired Boilers Environment. Oxid Met 92, 457–470 (2019). https://doi.org/10.1007/s11085-019-09941-x

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11085-019-09941-x