Abstract

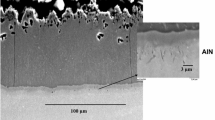

Severe sulfidation problems of water-wall tubes made from low-alloy steels for pulverized coal-fired boilers have been often recognized recently, due to the evolution to a strongly reducing atmosphere, which contains H2S, SO2. In an actual operating boiler, gas composition is not constant; it fluctuates between oxidizing and sulfidizing (reducing) atmospheres. There is still much uncertainty about the effect of the alternation between oxidizing and sulfidizing atmospheres to sulfidation behavior of water-wall tube materials. In this research, we try to clarify the effect of fluctuations in atmospheres on the sulfidation behavior of water-wall tube materials such as low-alloy steels. Corrosion tests of specimens which were made of low-alloy steels (STBA20, STBA22 and STBA24) were conducted by periodically switching the gas feed between supplying a sulfidizing atmosphere and an oxidizing atmosphere. After corrosion testing, it was revealed that the effect of oxidation/sulfidation fluctuation on the corrosion behavior was very small for the lowly sulfidizing atmosphere and air alternation. However, for the highly sulfidizing atmosphere and air alternation, the mass changes increase as fluctuation dwell-times increased. A thick porous outer layer of scale formed on the specimen exposed to long-term fluctuations and the most of the scale was spalled. Scale spallation became more pronounced in more highly sulfidizing atmospheres and as the fluctuation dwell-time increased. During long-term fluctuations between a highly sulfidizing atmosphere and air, the iron sulfides that form initially are oxidized, and that this reaction reduces the volume of the scale and increases its porosity. Oxidation of the sulfides produced shrinkage only on gas side of the scale, and the resulting stress made the scales curl and eventually spallation. Specimens exposed to short-term fluctuations between a highly sulfidizing atmosphere and air were tend to form a thin iron oxide layer because the oxidation of iron sulfides proceeds more rapidly than the sulfidation of iron oxides. The corrosiveness of sulfidizing atmosphere influence to the sulfidation rate of iron oxides.

Similar content being viewed by others

References

S. C. Kung and W. T. Bakker, Corrosion 2000, (NACE International, Houston, Paper No. 246, 2000).

S. C. Kung, Mater. Perform. 36, 36 (1997).

S. Najima and M. Morinaga, CRIEPI Research Report, (No. Q10018, 2011).

S. Najima, M. Morinaga and H. Shirai, Mater. Sci. Forum 696, 260 (2011).

S. Najima and M. Morinaga, CRIEPI Research Report, (No. Q10019, 2011).

V. Behrani and P. M. Singh, Corrosion 64, 883–890 (2008).

F. Gesmundo, C. Roos, F. Viani and D. Oquab, High Temp. Mater. Process 17, 145 (1998).

W. Sun and S. Nesic, Nace Corrosion 2007, (Paper No. 07655, 2007).

A. S. Khanna, Introduction to High Temperature Oxidation and Corrosion, (ASM International, Materials Park, 2002).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Najima, S., Morinaga, M. & Hayashi, S. Effect of Atmospheric Fluctuations on the Sulfidation Behavior of Low-Alloy Steel in Simulated Pulverized-Coal Combustion Environments. Oxid Met 84, 633–646 (2015). https://doi.org/10.1007/s11085-015-9592-x

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11085-015-9592-x