Abstract

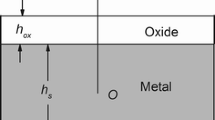

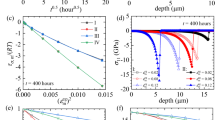

Stress is induced in a thermally grown oxide scale during high-temperature oxidation. Under certain conditions, the oxidation causes plastic deformation. An inhomogeneous growth strain formulation is proposed based on evolution equations. Using the inhomogeneous growth strain, a reaction–diffusion–stress coupling elastic–plastic model, which accounts for factors, such as the chemical reaction, kinetics of the oxide scale and diffusion of reactant species, is developed for the analysis of stress and effects of stress on these factors in the oxide scale during high-temperature oxidation. Numerical results reveal large compressive stresses and a significant stress gradient in the oxide scale with the largest compressive stress at the oxide/substrate interface and the lowest compressive stress at the oxygen/oxide interface, which is consistent with experimental observations. The stress developed in the oxide scale has an influence on the oxidation reaction rate and distribution of the reactant species concentration, which in return affects the stress distribution.

Similar content being viewed by others

References

U. Evans, Transactions of the Electrochemical Society 91, 547 (1947).

J. Stringer, Corrosion Science 10, 513 (1970).

V. Tolpygo and D. Clarke, Oxidation of Metals 49, 187 (1998).

T. Ueno, Transactions of Japan Institute of Metals 15, 167 (1974).

T. Mitchell, D. Voss and E. Butler, Journal of Materials Science 17, 1825 (1982).

R. Bedworth and N. Pilling, Journal of the Institute of Metals 29, 529 (1923).

F. Rhines and J. Wolf, Metallurgical Transactions 1, 1701 (1970).

V. Tolpygo, J. Dryden and D. Clarke, Acta Materialia 46, 927 (1998).

D. R. Clarke, Acta Materialia 51, 1393 (2003).

B. Panicaud, J. Grosseau-Poussard and J. Dinhut, Computational Materials Science 42, 286 (2008).

S. Maharjan, X. Zhang and Z. Wang, Oxidation of Metals 77, 93 (2012).

R. Krishnamurthy and D. J. Srolovitz, Acta Materialia 51, 2171 (2003).

H. Zhou, J. Qu and M. Cherkaoui, Mechanics of Materials 42, 63 (2010).

K. Loeffel, L. Anand and Z. M. Gasem, Acta Materialia 61, 399 (2013).

F. Yang, Materials Science and Engineering A 409, 153 (2005).

X. L. Dong, X. F. Fang, X. Feng and K. C. Hwang, Journal of the American Ceramic Society 96, 44 (2013).

Y. Suo and S. Shen, Journal of Applied Physics 114, 164905 (2013).

S. Hu and S. Shen, Acta Mechanica 224, 2895 (2013).

D. Zhu, J. H. Stout and D. A. Shores, in High Temperature Corrosion and Protection of Materials 4, Pts 1 and 2, (Transtec Publications Ltd, Zurich-Uetikon, 1997), p. 333.

D. H. Bradhurs and P. M. Heuer, Journal of Nuclear Materials 37, 35 (1970).

E. Kobeda and E. A. Irene, Journal of Vacuum Science & Technology B 6, 574 (1988).

B. Cox, Journal of Nuclear Materials 336, 331 (2005).

A. Atkinson, Reviews of Modern Physics 57, 437 (1985).

J. Li, Scripta Metallurgica 15, 21 (1981).

N. Swaminathan and J. Qu, Modelling and Simulation in Materials Science and Engineering 17, 16 (2009).

N. Swaminathan, J. Qu and Y. Sun, Philosophical Magazine 87, 1705 (2007).

F. Larche and J. Cahn, Journal of Research of the National Bureau of Standards 89, 467 (1984).

E. A. García and J. Kovacs, Journal of Nuclear Materials 210, 78 (1994).

J. Favergeon, T. Montesin and G. Bertrand, Oxidation of Metals 64, 253 (2005).

Acknowledgments

The supports from NSFC (Grants Nos. 11025209, 11372238, 11302161, 11321062 and 11302162) are appreciated.

Conflict of interest

The authors declare that they have no conflict of interest.

Ethical approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Informed consent

Additional informed consent was obtained from all individual participants for whom identifying information is included in this article.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, H., Suo, Y. & Shen, S. Reaction–Diffusion–Stress Coupling Effect in Inelastic Oxide Scale During Oxidation. Oxid Met 83, 507–519 (2015). https://doi.org/10.1007/s11085-015-9531-x

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11085-015-9531-x