Abstract

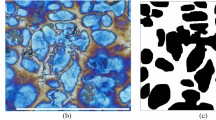

Engine cylinder blocks and heads, made of compacted graphite iron, are subjected to prolonged periods of cyclic heating and cooling. These conditions may give rise to the decomposition of the pearlite matrix accompanied by the formation of lower-density graphite and oxides, which will lead to an increase of material volume. The microstructural instability deteriorates the physical and mechanical properties of CGI and accordingly the thermal fatigue properties. In the present work it was shown that the extent and mechanism of volume change are drastically affected by the presence of an oxide atmosphere. It was found that after annealing under atmospheric conditions internal oxidation largely inhibited the progress of pearlite decomposition and therefore much smaller growth rates were obtained as compared to those observed under vacuum conditions in the dilatometer. After 16 h of annealing time at 700 °C in vacuum, the CGI samples exhibited 6 times faster growth kinetics as compared to annealing in open atmosphere.

Similar content being viewed by others

References

J.R. Davis (Ed.), Cast irons. ASM Specialty Handbook, ASM International, Materials Park, OH 44073-0002, 407 (1996) .

V. M. Yuzvak, I. P. Volchok and V. I. Gontarenko, Metal Science and Heat Treatment 25, 569 (1983).

S. Y. Buni, N. Raman and S. Seshan, Sadhana 29, (1), 117 (2004).

K. R. Ziegler and J. F. Wallace, AFS Transactions 92, 735 (1984).

K. Roehrig, AFS Transactions 78–02, 75–88 (1978).

D.G. White, L. I. M., A. C. T., Growth and Scaling Characteristics of Cast Irons with Undercooled and Normal Flake Graphite, BCIRA Journal, 11(Report 689), 223 (1963).

H. D. Merchant, Oxid Metals 2, (2), 145 (1970).

J.R. Kattus and B. McPherson, Report on Properties of Cast Iron at Elevated Temperatures, ASTM Special Technical Publication No. 248. Philadelphia, (1959).

D. Jedrzejczyk, M. Hajduga, R. Lorek, High Temperature Oxidation as the Method of Surface Treatment of Cast Iron, METAL (2008), 13–15 May, Hradec nad Moravici

C. F. Walton and T. J. Oper (eds.), Text Book, Iron Casting Handbook, (Iron castings society, Cleveland, 1981).

D. Brandon and W. D. Kapplan, Text book, Microstructural Characterization of Materials, 2nd ed, (Wiley, Hoboken, 2008).

S.Ghodrat, Thermo-Mechanical Fatigue of Compacted Graphite Iron (CGI) in Diesel Engine Components, Chapter 4, Delft university of Technology, PhD Thesis, 2013.

J. Kucera and K. Stransky, Diffusion in Iron, Iron Solid Solutions and Steels. Materials Science and Engineering 52, 1 (1982).

Acknowledgments

This research was carried out under project number MC2.06270 in the framework of the Research Program of the Materials innovation institute M2i (www.m2i.nl). Authors would like to thank DAF Trucks N.V. Central Laboratories for their contributions and provision of material for this research.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ghodrat, S., Janssen, M., Kestens, L.A.I. et al. Volume Expansion of Compacted Graphite Iron Induced by Pearlite Decomposition and the Effect of Oxidation at Elevated Temperature. Oxid Met 80, 161–176 (2013). https://doi.org/10.1007/s11085-013-9406-y

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11085-013-9406-y