Abstract

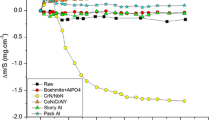

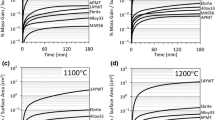

Steam oxidation of heat exchanger tubing is of growing interest as increasing the efficiencies of conventional pulverised fuel fired power plants requires higher steam temperatures and pressures. These new, more severe steam conditions result in faster steam oxidation reactions, which can significantly reduce the lifetime of boiler components. This paper reports some results from an investigation into the impact of steam flow rates and sample orientation on the steam oxidation of surface ground superheater tube materials. The results show that an increased steam flow rate not only causes faster oxidation rates but also a change in oxide scale morphology. In case of T23, it triggers formation of micro-layered inner oxide, whereas for T92 it promotes the formation of an outer haematite layer. For austenitic steels, the faster steam flow increases the formation of initially protective oxide scales, but also accelerates the growth of oxide nodules with prolonged exposure times.

Similar content being viewed by others

References

I. Wright and R. Dooley, International Materials Reviews 55, 129–167 (2010).

I. Wright and R. Dooley, Materials at High Temperatures 28, 40–57 (2011).

I. Wright, P. Tortorelli, and M. Schutze, Oxide growth and exfoliation on alloys exposed to steam, EPRI Technical Report No. 1013666 (EPRI, 2007).

R. Viswanathan and W. Bakker, Proc. of 2000 International Joint Power Conference, Miami (2000).

J. Sarver and J. Tanzosh, 28th International Technical Conference on Coal Utilisation and Fuel Systems (Clearwater, USA, 2003).

A. Hansson and M. Montgomery, Materials Science Forum 522–523, 181–188 (2006).

P. Ennis and W. Quadakkers, International Journal of Pressure Vessels and Piping 84, 82–87 (2007).

R. Viswanathan, J. Sarver and J. Tanzosh, Journal of Materials Engineering and Performance 31, 255–274 (2005).

J. Zurek, M. Michalik, F. Schmitz, T. Kern, L. Singheiser and W. Quadakkers, Oxidation of Metals 63, 401–422 (2005).

N. Cory, T. Herrington and L. Tomlinson, Corrosion Science 29, 939–965 (1989).

M. Nakai, K. Nagai, Y. Murata and M. Morinaga, Corrosion Science 48, 3869–3885 (2006).

X. Guo, Y. Sasaki, Y. Kashiwaya and K. Ishii, Metallurgical and Materials Trans B 35B, 517–522 (2004).

D. Young, Materials Science Forum 595–598, 1189–1197 (2008).

H. Asteman, J. Svensson, M. Norell and L. Johansson, Oxidation of Metals 54, 11–26 (1999).

H. Asteman, J. Svensson and L. Johansson, Oxidation of Metals 57, 193–216 (2002).

M. Halvarsson, J. Tang, H. Asteman, J. Svensson and L. Johansson, Corrosion Science 48, 2014–2035 (2006).

J. Ehlers, D. Young, E. Smaardijk, A. Tyagi, H. Penkalla, L. Singheiser and W. Quadakkers, Corrosion Science 48, 3428–3454 (2006).

A. Rahmel and J. Toborski, Corrosion Science 5, 333–340 (1965).

W. J. Quadakkers and J. Zurek, Oxidation in steam and steam/hydrogen environments, in Shreir’s Corrosion, ed. J. A. Richardson et al., Vol. 1 (Elsevier, Amsterdam, 2010), pp 407–456.

P. F. Tortorelli, A. S. Sabau, J. P. Shingledecker, and I. G. Wright, Overview of status and needs of EPRI-ORNL model for scale exfoliation in steam boilers, in EPRI-NPL Workshop on Scale Exfoliation from steam-touched surfaces (London, 2012).

D. J. Young, High Temperature Oxidation and Corrosion of Metals (Elsevier, 2008), pp. 455–495.

Acknowledgments

The authors would like to acknowledge the support of The Energy Programme, which is a Research Councils UK cross council initiative, and specifically the Supergen programme (Grants GR/S86334/01 and EP/F029748) and the following companies: Alstom Power Ltd., Doosan Babcock, E.ON, National Physical Laboratory, Praxair Surface Technologies Ltd., QinetiQ, Rolls-Royce plc, RWE npower, Siemens Industrial Turbomachinery Ltd., and Tata Steel.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lukaszewicz, M., Simms, N.J., Dudziak, T. et al. Effect of Steam Flow Rate and Sample Orientation on Steam Oxidation of Ferritic and Austenitic Steels at 650 and 700 °C. Oxid Met 79, 473–483 (2013). https://doi.org/10.1007/s11085-013-9358-2

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11085-013-9358-2