Abstract

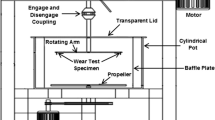

An investigation into the erosion–oxidation behavior of chromized–aluminized 9% chromium steel has been carried out in a fluidized-bed erosion–oxidation rig in air at temperatures of 550 °C to 700 °C for particle impact angles of 30° and 90°, at speeds of 7.0–9.2 m s−1. After exposure for 200 h, the mean-thickness changes were determined, and the specimens were examined and analyzed by scanning electron microscopy and X-ray diffraction.

The results show that the chromized–aluminized specimens experience only relatively small amounts of material loss for 30° particle impacts but greater amounts for 90° particle impacts; such angle dependence is typical of a brittle erosion process. Under both impact angles, the thickness losses increase with increase in speed, and also, in temperature up to 650 °C, but then decrease with further increase in temperature. This change in the behavior between 650 and 700 °C is due to an increase in ductility of the coating and a greater contribution from oxidation. The two coating layers (an outer Al13Cr2 and an inner α-chromium layer) show similar behavior, i.e., have lower material loss rates under 30° impacts than under 90° impacts. As the oxidation rate of the α-chromium layer is greater than that of the outer layer, the oxide scale plays a greater role in the erosion process for the former, particularly under 30° impacts. These observations are discussed in terms of the thickness changes and the morphologies of the damaged surfaces, with the emphasis being put on the relative roles of growth of the oxide scales and removal of such scales (and the underlying coating) by the impacting particles.

Similar content being viewed by others

References

R. Viswanathan, and W.T. Bakker, in Proceedings of International Joint Power Generation Conference 2000 Miami Beach, Florida, USA, (American Society of Mechanical Engineers, New Yours, USA, 2000) paper 15049.

J. P. T. Vossen, P. Gawenda, K. Rahts, M. Röhrig, M. Schorr, and M. Schütze, Materials at High Temperature 14, 387 (1997).

G. Wahl, Thin Solid Films 107, 417 (1983).

R. Mevrel, Materials Science and Engineering A120, 13 (1989).

F. J. Perez, F. Pedraza, M. P. Hierro, J. Balmain, and G. Bonnet, Oxidation of Metals 58, 563 (2002).

F. J. Perez, M. P. Hierro, F. Pedraza, M. C. Carpintero, C. Gomez, and R. Tarin, Surface and Coatings Technology 145, 1 (2001).

Y. Zhang, B. A. Pint, J. A. Haynes, and P. F. Tortorelli, Oxidation of Metals 62, 103 (2004).

K. Natesan, Materials Science and Engineering, A258, 126 (1998).

P. S. Liu, K. M. Liang, S. R. Gu, Surface and Coatings Technology 137, 60 (2001).

E. Huttunen-Saarivirta, F. H. Stott, V. Rohr, and M. Schütze, Materials at High Temperature 23, 1 (2006).

E. Huttunen-Saarivirta, F. H. Stott, V. Rohr, and M. Schütze, Corrosion Science 49, 2844 (2007).

C. Rosado, and M. Schütze, Materials and Corrosion 54, 831 (2003).

V. Rohr, Developpement de Revetements pour les Aciers D’Echangeurs Thermiques et Amelioration de leur Resistance a la Corrosion en Environnement Simulant les Fumees de Combustion de Charbon, PhD Thesis, Institut National Polytechnique de Toulouse (2005).

V. Rohr, M. Schütze, E. Fortuna, D. N. Tsipas, A. Milewska, and F. J. Perez, Materials and Corrosion 56, 874 (2005).

V. Rohr, and M. Schütze, Materials Science Forum 461, 401 (2004).

C. A. C. Sequeira, A. M. G. Pacheco, and C. M. G. S. Nunes, Surface Engineering 3, 247 (1987).

I. A. Menzies, and D. Mortimer, Corrosion Science 5, 539 (1965).

J.-W. Lee, and J. G. Duh, Surface and Coatings Technology 177–178, 525 (2004).

Y. Liu, and A. V. Levy, Surface and Coatings Technology 52, 119 (1992).

I. Finnie, in Corrosion-Erosion of Materials. K. Natesan, ed. (American Institute of Mining, Metallurgical and Petroleum Engineers, New York, USA) (1980).

R. Wellman, and J. R. Nicholls, Wear 256, 907 (2004)

A. Levy, and G. Hickey, Wear 108, 61 (1986).

M. Schütze in Corrosion and Environmental Degradation M. Schütze ed. Vol I. (Wiley-VCH Verlag GmbH, Weinheim Germany) (2000).

C. T. Kang, F. S. Pettit, and N. Birks, Metallurgical Transactions 18A, 1785 (1987).

M. M. Stack, F. H. Stott, and G. C. Wood, Wear 162(164), 706 (1993).

Acknowledgements

The authors wish to express their gratitude to the European Commission for the funding allocated to this study through a Research Training Network: SUNASPO (contract HPRN-CT-2001-00201). In addition, the Academy of Finland (decisions 105399 and 106160) and the Jenny and Antti Wihuri Foundation are acknowledged for further financial support to E. H.-S.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Huttunen-Saarivirta, E., Stott, F.H., Rohr, V. et al. Erosion–Oxidation Behavior of Chromized–Aluminized 9% Chromium Steel under Fluidized-Bed Conditions at Elevated Temperature. Oxid Met 68, 113–132 (2007). https://doi.org/10.1007/s11085-007-9064-z

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11085-007-9064-z