Abstract

Iron oxide minerals are probable constituents of the sediments present in geothermal regions of the primitive earth. They might have adsorbed different organic monomers (amino acids, nucleotides etc.) and catalyzed polymerization processes leading to the formation of the first living cell. In the present work we tested the catalytic activity of three forms of iron oxides (Goethite, Akaganeite and Hematite) in the intermolecular condensation of each of the amino acids glycine and L-alanine. The effect of zinc oxide and titanium dioxide on the oligomerization has also been studied. Oligomerization studies were performed for 35 days at three different temperatures 50, 90 and 120°C without applying drying/wetting cycling. The products formed were characterized by HPLC and ESI-MS techniques. All three forms of iron oxides catalyzed peptide bond formation (23.2% of gly2 and 10.65% of ala2). The reaction was monitored every 7 days. Formation of peptides was observed to start after 7 days at 50°C. Maximum yield of peptides was found after 35 days at 90°C. Reaction at 120°C favors formation of diketopiperazine derivatives. It is also important to note that after 35 days of reaction, goethite produced dimer and trimer with the highest yield among the oxides tested. We suggest that the activity of goethite could probably be due to its high surface area and surface acidity.

Similar content being viewed by others

Introduction

Amino acid condensation catalyzed by inorganic oxide surfaces is a widely recognized scenario for the prebiotic peptide formation on the planets of the Earth-like group (Bujdak and Rode 1996; 1997a, b; 1999a, b; Lahav 1994; Lahav et al. 1978; Porter et al. 1998; Rode et al. 1999; Smith 1998; Zamaraev et al. 1997). Most of the works reported in such studies have involved clay minerals. The results obtained strongly support the heterogeneous condensation hypothesis, but at the same time gave poor insight into chemical mechanism on the role of different surfaces. This was probably due to the complexity involved in minerals surface chemistry, due to the presence of different active surface sites, surface functional groups to planes, layers, edges, etc. (Basiuk and Sainz-Rojas 2001). Metal oxides constitute an important component of the crust of the Earth and of other planets and their role in catalyzing different important reactions in the course of chemical evolution and origin of life cannot be ruled out. Synthetic ferrihydrite was found to act as amino acid adsorbent and promoter for peptide bond formation (Matrajit and Blanot 2004). Condensation of DL – glyceraldehydes to ketohexoses in the presence of iron (III) oxide hydroxide has also been reported (Weber 1992). The iron oxide hydroxide minerals, goethite and akaganeite were likely constituents of the sediments present in, for instance, geothermal regions of the primitive Earth. These might have adsorbed organics and catalyzed the condensation processes which eventually led to the origin of life. The binding and reactions of nucleotides and polynucleotides on iron oxide hydroxide polymorphs has been studied (Holm et al. 1993). Recently iron oxides (Goethite, Akaganeite and Hematite) were shown to catalyze the formation of nucleobases from formamide (Shanker et al. 2011).

In an effort to provide more insight into the catalytic activity of oxides (of Fe, Zn and Ti) on peptide bond formation, the oligomerization of glycine and alanine in the temperature range 50–120°C was carried out. The metal oxides chosen have different surface area, surface acidity which are vital factor to affect the catalytic activity of a catalyst.

Experimental

Materials and Methods

Ferric nitrate (Merck), potassium hydroxide (Merck), ferric chloride (Merck), glycine, L-alanine (≥99.5%) were purchased from Sigma. All other chemicals used were of analytical grade and were used without further purification. Millipore water was used throughout the studies.

Synthesis and Characterization of the Iron Oxides (Goethite, Akaganeite and Hematite)

We prepared iron oxides (goethite, akaganeite and hematite) as described by (Cornell and Schwertmann 2003). The oxides were characterized as pure materials by X-ray diffraction (XRD), FE-SEM (Field emission scanning electron microscopy) and analytical TEM (Transmission electron microscopy), by comparing the spectra and diffraction lines to those already published. The products thus synthesized were then used for the oligopeptide formation experiments. Details of the characterization (XRD spectra, diffraction lines, diffraction rings, FE-SEM and TEM images) were the same as reported earlier (Shanker et al. 2011).

Oligopeptide Formation

The oxides (goethite, akaganeite, hematite, zinc oxide and titanium dioxide; 0.1 g each) were separately weighed out into glass tubes (150 × 15 mm) and impregnated with an aqueous solution of each of the amino acids, glycine or L-alanine (0.1 ml, 0.01 M). Blank tubes containing no mineral were similarly prepared by adding amino acid solutions. The tubes and their contents were dried at 90°C for 3 h and used for the investigation of peptide bond formation. The samples were heated at three different temperatures of 50°C, 90°C, and 120°C for 1–35 days. The reaction was monitored after every 7 days. Fluctuating drying/wetting conditions were not studied.

The samples were heated at three different temperatures of 50°C, 90°C, and 120°C for 1–35 days. The reaction was monitored after every 7 days. The contents of the tubes were washed with 1 ml of 0.1 M calcium chloride solution to leach out adsorbed amino acids and related reaction products. The supernatant liquid was filtered and divided into two parts; one part of the filtrate was used for HPLC analysis while other for ESI-MS analysis.

HPLC Analysis

All solutions obtained from the reaction systems were analyzed with HPLC (Waters 2489, binary system) equipped with a column of Waters (Spherisorp 5 μm ODS2 4.6 mm × 250 mm). UV detection was performed at 200 nm wavelength. The mobile phase compositions were 10 mM sodium hexane sulphonate acidified with phosphoric acid to pH ~ 2.5 (solvent A) and acetonitrile of HPLC grade (solvent B) with a flow rate of 1 ml/min. Representative chromatograms are shown in Figs. 1, 2, 3 and 4. The reaction products were identified by retention times and co-injection method. Yields of the products were determined comparing peak area of products to the standards Figs. 5, 6, 7, 8 and 9.

Electrospray Ionization–Mass Spectrometry Analysis

A Bruker Esquire 4000 (Bruker Daltonic, Bremen, Germany) ion trap mass spectrometer interfaced to an electrospray ionization (ESI) source was used for mass analysis and detection. Ionization of analytes was carried out using the following setting of ESI: nebulizer gas flow 10 psi, dry gas 5 L min−1, dry temperature 300°C, capillary voltage 4,000 V. Calibration MSn spectra were obtained after isolation of the appropriate precursor ions under similar experimental conditions. Figures 10 represent the ESI MS spectra of products obtained when glycine and alanine were heated at 90°C for 35 days in the presence of goethite.

Results and Discussion

In the control experiments with glycine only formation of a trace of Cyclic (Gly)2 and (Gly)2 was observed after 35 days however, formation of a peptide in the blank experiment of alanine was not at all observed, similar to the results reported by Bujdak and Rode (1999a, b).

Table 1 lists the yields of products obtained by heating glycine and alanine in the presence of iron oxides (goethite, akaganeite and hematite) and zinc & titanium dioxide at temperatures 50°C, 80°C and 120°C for 35 days. Representative HPLC chromatograms are shown in Figs. 1, 2, 3 and 4. The reaction products were identified by retention times and co-injection method. The overall yield of products as the function of time and temperature are given by Figs. 5, 6, 7, 8 and 9. Yields of the products were determined comparing peak area of products to the standards.

Formation of peptides up to trimer was observed with glycine only whereas alanine afforded only its dimer. Glycine in the presence of Goethite afforded formation of (Gly)3 (11.7%) along with (Gly)2 (23.2%) and Cyclic(Gly)2 (7.3%) while alanine afforded (Ala)2 (10.65%) and Cyclic(Ala2) (2.2%) after 35 days of heating at 90°C. ZnO and TiO2 showed formation of dimer only of glycine or alanine after 35 days of heating at 90°C.

The results of formation of peptide bond at 50°C suggest that peptide formation can also occur at lower temperatures and do not require the presence of localized heat sources, such as volcanoes and hydrothermal vents. Thus, in the presence of iron oxides (which are one of the most distributed inorganic oxides in the Earth-like planets’ crust), abiotic peptide synthesis might be a highly feasible process at a very short astronomical time scale.

All the oxides afforded formation of cyclic anhydride along with dimer of amino acid. Trimer of glycine was found in the presence of goethite only.

The formation of diketopiperazine was favored at higher temperature, 120°C (Table 1) with all the oxides because that the amount of adsorbed water (i.e. the thickness of hydrate layer at the oxides surface) was relatively low as compared to ambient temperatures that shift equilibrium of dehydration reactions. Under such conditions, the cyclization of gly2 and ala2 into diketopiperazine is much more favorable than peptide chain elongation. Thus it would be quite natural to detect gly3, at lower temperature 90°C, though the overall reaction rate decreases.

Figure 10 represents the ESI MS spectra of products obtained when glycine and alanine were each heated at 90°C for 35 days in the presence of Goethite. In the MS spectra of glycine, mass 76.1 corresponds to [Gly+H]+, 115 for [CycGly2+H]+, 132.9 for [Gly2+H]+ and 189.9 for [Gly3+H]+ . The ms spectra of alanine mass 90.1 corresponds to [Ala+H]+, 115 for [CycAla2+H]+ and 160.9 for [ala2+H]+.

The results of oligomerization of simple amino acids supports the view of Holm et al. that β-FeOOH.Cln is an interesting candidate as prebiotic replication matrix (Holm et al. 1983). Akaganeite is of particular interest as it appears to have a structure suitable for catalytic effects and is the main solid Fe(III) phase crystallizing during oxidation of hydrothermal brines. The Red Sea and other sea floors are proposed as spreading centers and possess most of the characteristics that are necessary for prebiotic formation of organic substances (Ingrmanson and Dowler 1977). Under such conditions catalytic polymerization of prebiotic molecules after sorption of the monomeric organic molecules like amino acids on crystalline host structures may have an important role.

It is important to note that among the three iron oxides, goethite is the most efficient, as it produced longer oligomers of amino acids as well as high yield of both glycine and alanine. Akaganeite and hematite produced glycine and alanine oligomers in comparatively low yields. Hematite favored the formation diketopiperazine derivatives. The observed yield of the products with three iron oxides studied followed the trend;

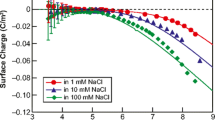

Catalytic efficiency of iron oxides can be explained on the basis of surface area and surface acidity of the catalyst used. The observed results clearly reflect the role of surface area of the catalysts having potent chemical functional groups. The most reasonable explanation for the formation of oligopeptides at the surface of iron oxides is the specific surface area and surface acidity of surface hydroxyl groups. The observed trend is in conformity with the decreasing surface area of iron oxides. As could be observed from the data of surface area that goethite, having maximum surface area (57.40 m2/g) is the most effective compared to akaganeite (30.37 m2/g) and hematite (7 m2/g). Besides surface area, surface acidity of iron oxides might also be responsible for the higher yield. Free hydroxyl groups on the surface of an iron oxide in aqueous environment are chemically highly potent and could catalyze the reaction through intermolecular H-bonding. These surface hydroxyl groups may easily interact with the amino acids. The higher the number of surface hydroxyl groups, the more will be the interaction with the amino groups. Further, the number of surface hydroxyl groups exposed directly depends on the specific surface area of the materials. In the case of goethite, the surface area is the highest compared to akaganeite and hematite, with a higher number of surface hydroxyl groups to interact with amino acids and hence produced the greatest yield of products.

In the presence of ZnO and TiO2, formation of oligopeptides also occurs under similar conditions. Glycine and alanine both afforded dimer. After 35 days yield remained approximately constant. Formation of oligopeptides was suggested to take place by the interaction between Lewis acid Ti4+ centers with negatively charged oxygens of amino acids.

Conclusions

-

1.

Iron oxides (goethite, akaganeite and hematite), ZnO and TiO2 are able to catalyze the formation of peptide bonds from glycine or alanine without applying drying/wetting cycling.

-

2.

Formation of peptide bond was observed even at 50°C after 7 days of heating. High temperature favored formation of diketopiperazine derivatives.

-

3.

Glycine on goethite produced Cyclic (Gly)2, (Gly)2 and (Gly)3, and with alanine, Cyclic (Ala)2 and (Ala)2. Akaganeite also produced the same products but in lesser yield, while hematite produced cyclic anhydride of glycine and alanine with a trace amount of dimer.

-

4.

Titanium dioxide and zinc oxides were also found to afford oligopeptides (dimer of glycine and alanine) after 35 days of heating.

References

Basiuk VA, Sainz-Rojas J (2001) Catalysis of peptide formation by inorganic oxides: high efficiency of alumina under mild conditions on the earth-like planets. Adv Space Res 27:225–230

Bujdak J, Rode BM (1996) The effect of smectite composition on the catalysis of peptide bond formation. J Mol Evol 43:326–333

Bujdak J, Rode BM (1997a) Silica, alumina, and clay-catalyzed alanine peptide bond formation. J Mol Evol 45:457–466

Bujdak J, Rode BM (1997b) Glycine oligomerization on silica and alumina. React Kinet Catal Lett 62:281–286

Bujdak J, Rode BM (1999a) The effect of clay structure on peptide bond formation catalysis. J Mol Catal A 144:129–136

Bujdak J, Rode BM (1999b) Silica, alumina and clay catalyzed peptide bond formation: enhanced efficiency of alumina catalyst. Orig Life Evol Biosph 29:451–461

Cornell RM, Schwertmann U (2003) The iron oxides: structure, properties, reactions, occurrences and uses, 2nd edn. Wiley-VCH GmbH& Co. KGaA, Weinheim, pp 525–537

Holm NG, Dowler MJ, Wadsten T, Arrhenius G (1983) β-FeOOH.Cln (akaganéite) and Fe1−xO (wüstite) hot brine from the Atlantis II Deep (Red Sea) and uptake of amino acids by synthetic β-FeOOH.Cln. Geochim Cosmochim Acta 47:1465–1470

Holm NG, Ertem G, Ferris JP (1993) The binding and reactions of nucleotide and polynucleotide on iron oxide hydroxide polymorphs. Orig life Evol Biosph 23:195–215

Ingrmanson DE, Dowler MJ (1977) Chemical evolution and the evolution of the Earth’s crust. Orig Life 8:221–224

Lahav N (1994) Minerals and the origins of life: hypotheses and experiments in heterogeneous chemistry. Heterogen Chem Rev 1:159–186

Lahav N, White D, Chang S (1978) Peptide formation in the Prebiotic era: thermal condensation of glycine in fluctuating clay environments. Science 201:67–69

Matrajit G, Blanot D (2004) Properties of synthetic ferrihydrite as an amino acid adsorbent and a promoter of peptide bond formation. Amino Acids 26:153–158

Porter TL, Eastman MP, Hagerman ME, Price L, Shand RF (1998) Site-specific Prebiotic Oligomerization reactions of Glycine on the surface of Hectorite. J Mol Evol 47:373–377

Rode BM, Son HL, Suwannachot Y, Bujdak J (1999) The combination of salt-induced peptide formation reaction and clay catalysis: a way to higher peptides under primitive earth conditions. Orig Life Evol Biosph 29:273–286

Shanker U, Bhushan B, Bhattacharjee G, Kamaluddin A (2011) Formation of nucleobases in the presence of iron oxides: implication in chemical evolution and origin of life. Astrobiology 11:225–233

Smith JV (1998) Biochemical evolution. I. Polymerization on internal, Organophilic silica surfaces of Dealuminated Zeolites and Feldspars. Proc Natl Acad Sci USA 95:3370–3375

Weber AL (1992) Prebiotic sugar synthesis: Hexose and hydroxyl acid synthesis from glyceraldehydes catalyzed by Iron (III) hydroxide oxide. J Mol Evol 35:1–16

Zamaraev KI, Romannikov VN, Salganik RI, Wlasoff WA, Khramtsov VV (1997) Modelling of the Prebiotic synthesis of Oligopeptides: silicate catalysts help to overcome the critical stage. Orig Life Evol Biosph 27:325–337

Acknowledgement

This work was supported by the Indian Space Research Organization (ISRO), Bangalore, India. One of the authors, Uma Shanker is thankful to the Ministry of Human Resource and Development (MHRD), New Delhi, India for the award of a fellowship.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shanker, U., Bhushan, B., Bhattacharjee, G. et al. Oligomerization of Glycine and Alanine Catalyzed by Iron Oxides: Implications for Prebiotic Chemistry. Orig Life Evol Biosph 42, 31–45 (2012). https://doi.org/10.1007/s11084-012-9266-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11084-012-9266-5