Abstract

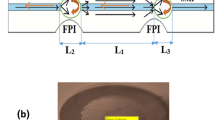

The detailed fabrication processes of fiber Mach-Zehnder interferometers (FMZIs) by nanosecond laser-induced micro-plasma and its simple micro-cavity size adjustment are proposed and demonstrated. The fabrication can be divided into 4 processes: (1) heat transfer, (2) micro-plasma formation, (3) micro-plasma expansion and ablation, (4) cooling down and micro-structure formation. The simple micro-cavity size adjustment is proposed based on the above understanding, instead of the “point processing” of femtosecond laser, here only the focus position is required to be moved. The fabricated FMZI exhibits a high sensitivity of -15,811 nm/RIU (refractive index unit) for the index sensing application.

Similar content being viewed by others

Data availability

No data is available for this work.

References

Albert, J., Shao, L.Y., Caucheteur, C.: Tilted fiber Bragg grating sensors. Laser Photonics Rev. 7(1), 83–108 (2013)

Chunyang, H., Hui, D., Xianli, L., Shaofei, D.: Temperature insensitive refractive index sensor based on single-mode micro-fiber Sagnac loop interferometer. Appl. Phys. Lett. 104(18), 181906 (2014)

Janik, M., Myśliwiec, A.K., Koba, M., Celebańska, A., Bock, W.J., Śmietana, M.: Sensitivity pattern of femtosecond laser micromachined and plasma-processed in-fiber Mach-Zehnder interferometers, as applied to small-scale refractive index sensing. IEEE Sens. J. 17(11), 3316–3322 (2017)

Jiang, L., Zhao, L., Wang, S., Yang, J., Xiao, H.: Femtosecond laser fabricated all-optical fiber sensors with ultrahigh refractive index sensitivity: modeling and experiment. Opt. Express. 19(18), 17591–17598 (2011)

Kostyuk, G., Sergeev, M., Zakoldaev, R., Yakovlev, E.: Fast microstructuring of silica glasses surface by NIR laser radiation. Opt. Lasers Eng. 68, 16–24 (2015)

Li, Z., Liao, C., Wang, Y., Dong, X., Liu, S., Yang, K., Wang, Q., Zhou, J.: Ultrasensitive refractive index sensor based on a Mach-Zehnder interferometer created in twin-core fiber. Opt. Lett. 39(17), 4982–4985 (2014)

Li, Z., Liao, C., Song, J., Wang, Y., Zhu, F., Wang, Y., Dong, X.: Ultrasensitive magnetic field sensor based on an in-fiber Mach-Zehnder interferometer with a magnetic fluid component. Photonics Res. 4(5), 197–201 (2016)

Li, Z., Liao, C., Chen, D., Song, J., Jin, W., Peng, G.-D., Zhu, F., Wang, Y., He, J., Wang, Y.: Label-free detection of bovine serum albumin based on an in-fiber Mach-Zehnder interferometric biosensor. Opt. Express. 25(15), 17105–17113 (2017)

Park, M., Lee, S., Ha, W., Kim, D.-K., Shin, W., Sohn, I.-B., Oh, K.: Ultracompact intrinsic micro air-cavity fiber Mach-Zehnder interferometer. IEEE Photonics Technol. Lett. 21(15), 1027–1029 (2009)

Rao, Y.-J.: In-fibre Bragg grating sensors. Meas. Sci. Technol. 8(4), 355 (1997)

Rao, Y.-J., Deng, M., Duan, D.-W., Yang, X.-C., Zhu, T., Cheng, G.-H.: Micro Fabry-Perot interferometers in silica fibers machined by femtosecond laser. Opt. Express. 15(21), 14123–14128 (2007)

Shuhao, C., Rymkevich, V., Sergeev, M., Samokhvalov, A.: Features of fused silica ablation by laser induced carbon microplasma. Opt. Quant. Electron. 52(2), 1–11 (2020)

Shuhao, C., Lijing, Z., Sergeev, M., Dmitriev, A., Jiang, Y., Petrov, A., Varzhel, S., Sheng, C., Li, L.: Fiber Mach-Zehnder interferometers fabricated by nanosecond pulses and applications in refractive index sensing.Optics Communications, 127150 (2021)

Sun, X.-Y., Chu, D.-K., Dong, X.-R., Li, H.-T., Hu, Y.-W., Zhou, J.-Y., Duan, J.-A.: Highly sensitive refractive index fiber inline Mach-Zehnder interferometer fabricated by femtosecond laser micromachining and chemical etching. Opt. Laser Technol. 77, 11–15 (2016)

Tian, Z., Yam, S.S., Loock, H.-P.: Refractive index sensor based on an abrupt taper Michelson interferometer in a single-mode fiber. Opt. Lett. 33(10), 1105–1107 (2008)

Veiko, V.P., Volkov, S.A., Zakoldaev, R.A., Sergeev, M.M., Samokhvalov, A.A., Kostyuk, G.K., Milyaev, K.A.: Laser-induced microplasma as a tool for microstructuring transparent media. Quantum Electron. 47(9), 842 (2017)

Wang, Y., Li, Y., Liao, C., Wang, D., Yang, M., Lu, P.: High-temperature sensing using miniaturized fiber in-line Mach-Zehnder interferometer. IEEE Photonics Technol. Lett. 22(1), 39–41 (2009)

Wang, Y.: Review of long period fiber gratings written by CO2 laser. J. Appl. Phys. 108(8), 11 (2010)

Wei, T., Han, Y., Tsai, H.-L., Xiao, H.: Miniaturized fiber inline fabry-perot interferometer fabricated with a femtosecond laser. Opt. Lett. 33(6), 536–538 (2008)

Zhao, L., Jiang, L., Wang, S., Xiao, H., Lu, Y., Tsai, H.-L.: A high-quality Mach-Zehnder interferometer fiber sensor by femtosecond laser one-step processing. Sensors. 11(1), 54–61 (2011)

Zhao, Y., Zhao, H., Lv, R., Zhao, J.: Review of optical fiber Mach-Zehnder interferometers with micro-cavity fabricated by femtosecond laser and sensing applications. Opt. Lasers Eng. 117, 7–20 (2019)

Acknowledgements

The author acknowledges the scholarship from the China Scholarship Council (201306840047). The authors also would like to thank Dr. Wang Dongdong at Nanjing University of Science and Technology, China, for insightful discussions and cordial help in the lab.

Funding

This work is supported by NSAF, China (No. U1830123), and the National Natural Science Foundation of China (No. 61627802).

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection and analysis were performed by Cai Shuhao. The first draft of the manuscript was written by Cai Shuhao, writing - review and editing were performed by Maksim Sergeev, Andrey Petrov, Sergey Varzhel, and Li Li, founding was acquired by Li Li. All authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no conflicts of interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Shuhao, C., Sergeev, M., Petrov, A. et al. The fabrication processes and simple micro-cavity size adjustment of fiber Mach-Zehnder interferometer by laser-induced micro-plasma. Opt Quant Electron 55, 321 (2023). https://doi.org/10.1007/s11082-023-04541-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11082-023-04541-1